High-current baffleless magnesium electrolytic tank

A magnesium electrolytic cell without separator technology, which is applied in the field of magnesium electrolysis, can solve the problems of research and development lag, poor sealing, serious corrosion, etc., and achieve obvious energy saving effects and lower tank pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

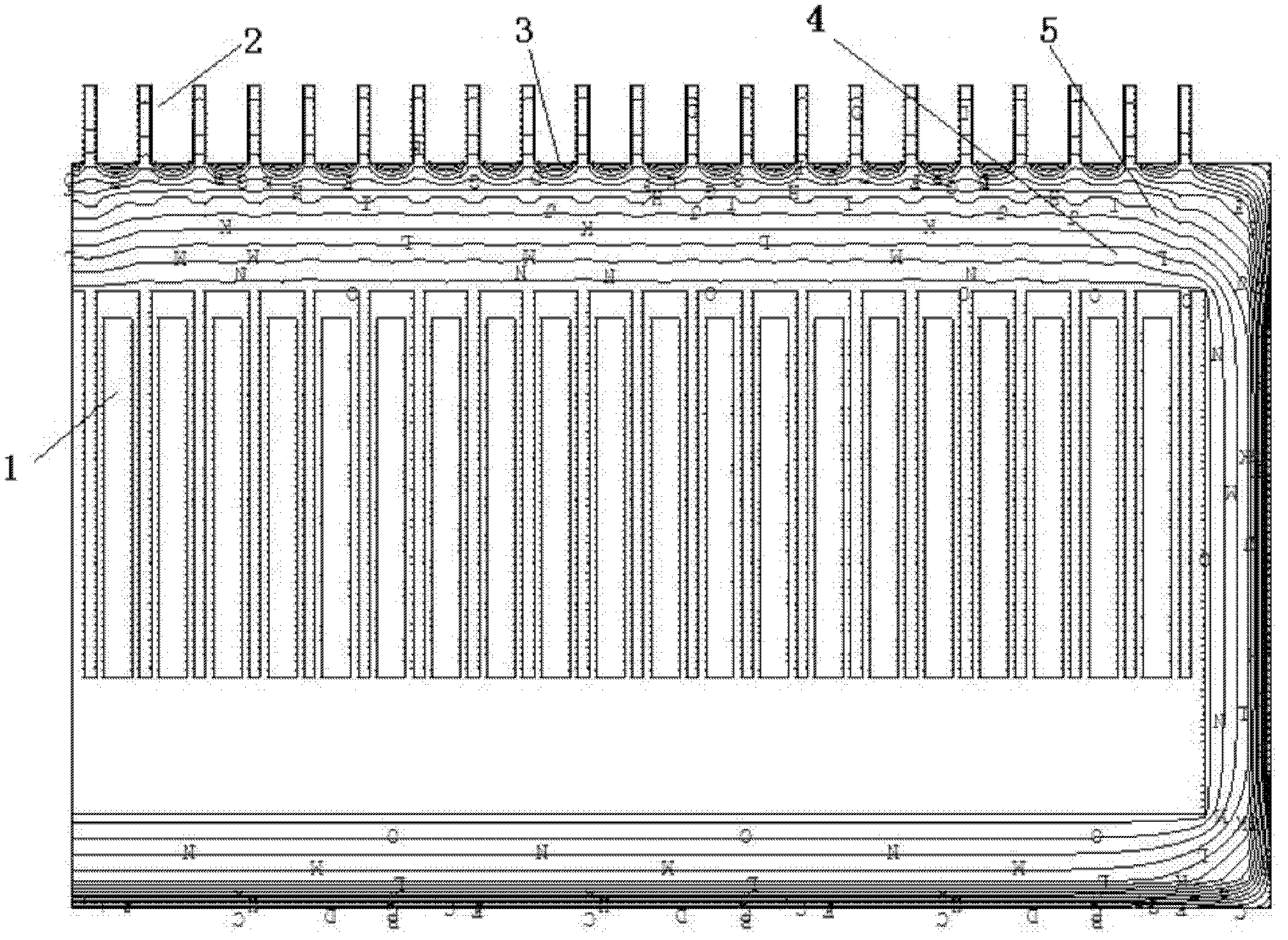

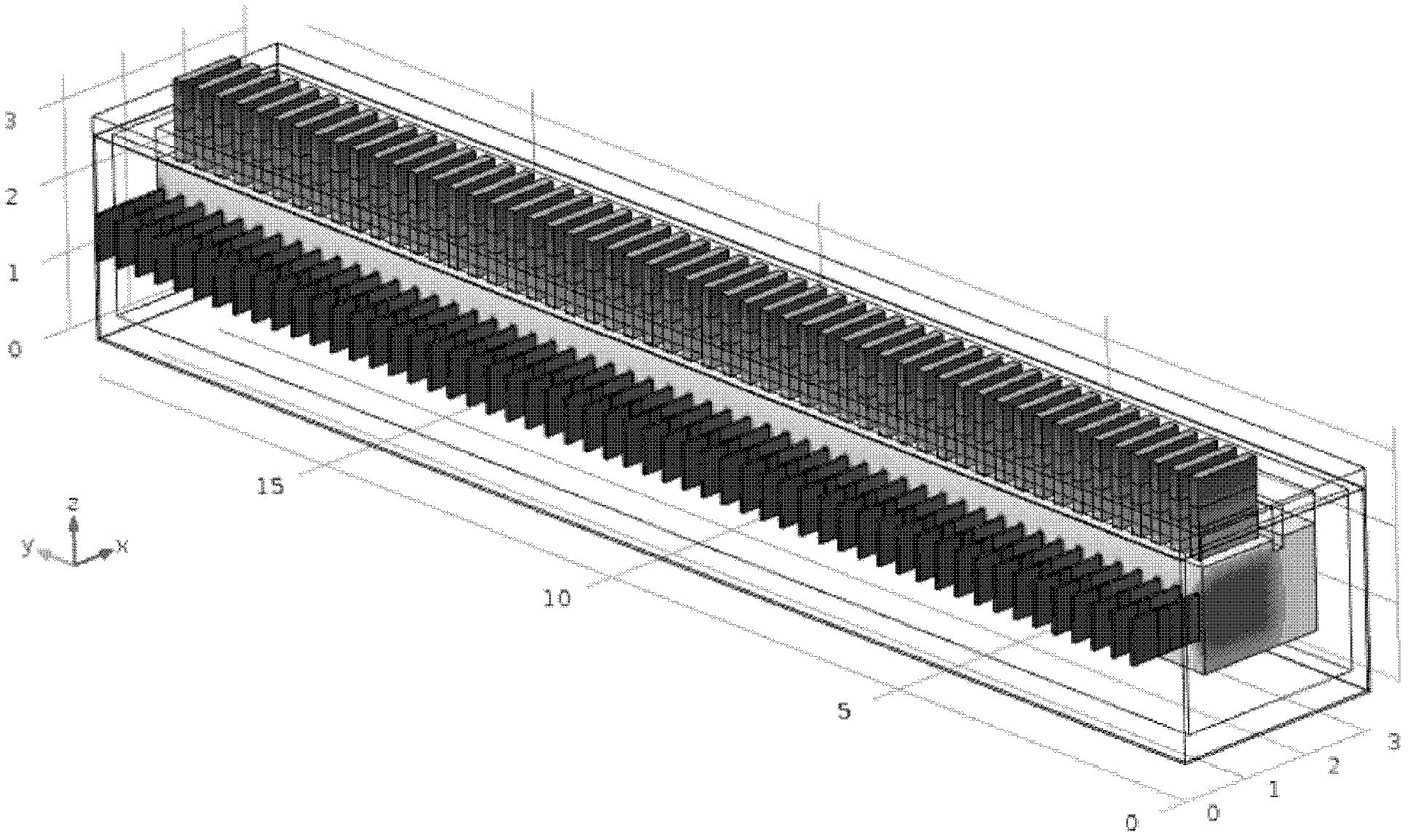

[0022] See attached Figure 1-3 , This kind of high-current magnesium electrolytic cell without separators, its basic components are anode 1, cathode 2, tank shell 3, refractory layer 4, insulation layer 5. After optimizing the electric field, thermal field and flow field, a separatorless magnesium electrolytic cell with a current intensity of 300kA was designed. The current efficiency of the electrolytic cell can reach 90% by calculation. The total length of the electrolytic cell is 12.7 meters. A total of 40 anodes and 41 cathodes are designed. The design current intensity is 300kA, the electrolysis design temperature is 700℃, the anode and cathode distance of the electrolytic cell is 0.04 meters, the cathode is 0.5m longer than the anode in the depth direction of the electrolytic cell, 0.1m longer in the direction of the magnesium chamber, and the electrolyte level is away from the cathode. The top is 0.2m, and the overall cell pressure drop is 4.5 volts. The temperature dis...

Embodiment 2

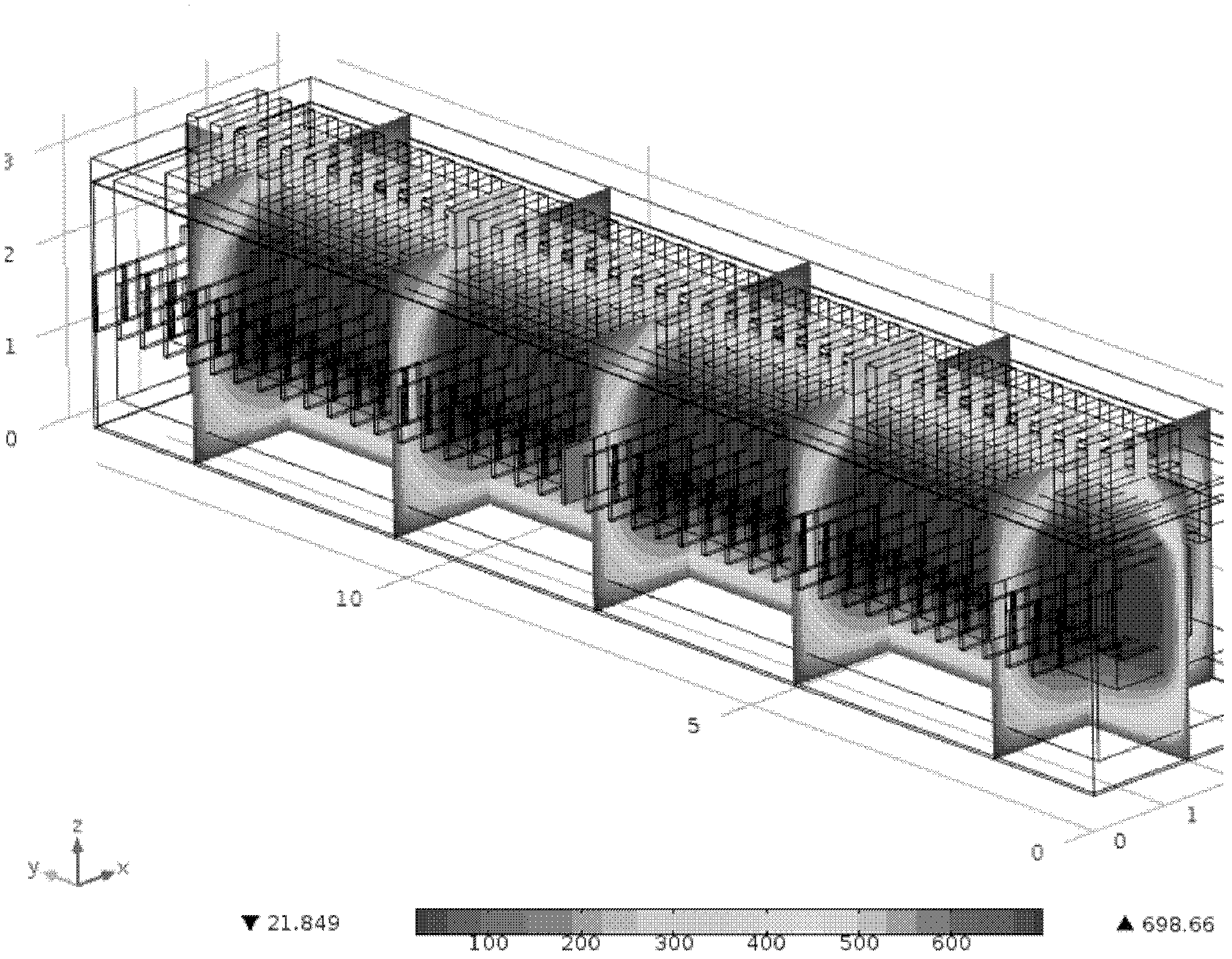

[0025] After optimizing the electric field, thermal field, and flow field, a separatorless magnesium electrolytic cell with a current intensity of 400kA was designed. The current efficiency of the electrolytic cell can reach 93% by calculation. A total of 54 anodes and 55 cathodes are designed, and the design current intensity is 400kA. The electrolysis design temperature is 700℃, the cathode and anode distance of the electrolytic cell is 0.04m, the cathode is 0.4m longer than the anode in the depth direction of the electrolysis cell, 0.2m longer in the direction of the magnesium chamber, and the electrolyte level is 0.3m from the top of the cathode. The voltage drop is 5V, and the voltage distribution of the electrolytic cell is calculated as image 3 :

[0026] by image 3 It can be seen that in the electrolytic cell, the anode head has the highest voltage because it is a voltage input, which is 5V, which is shown in red in the figure. The current flows out of the electrolytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com