Heat insulation curtain wall

A curtain wall and curtain wall panel technology, applied in the direction of walls, building components, insulation, etc., can solve the problems of poor environmental protection performance, reduce heat insulation effect, affect the overall appearance of the curtain wall, etc., achieve the improvement of heat insulation performance, improve the overall aesthetics, improve The effect of the factor of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

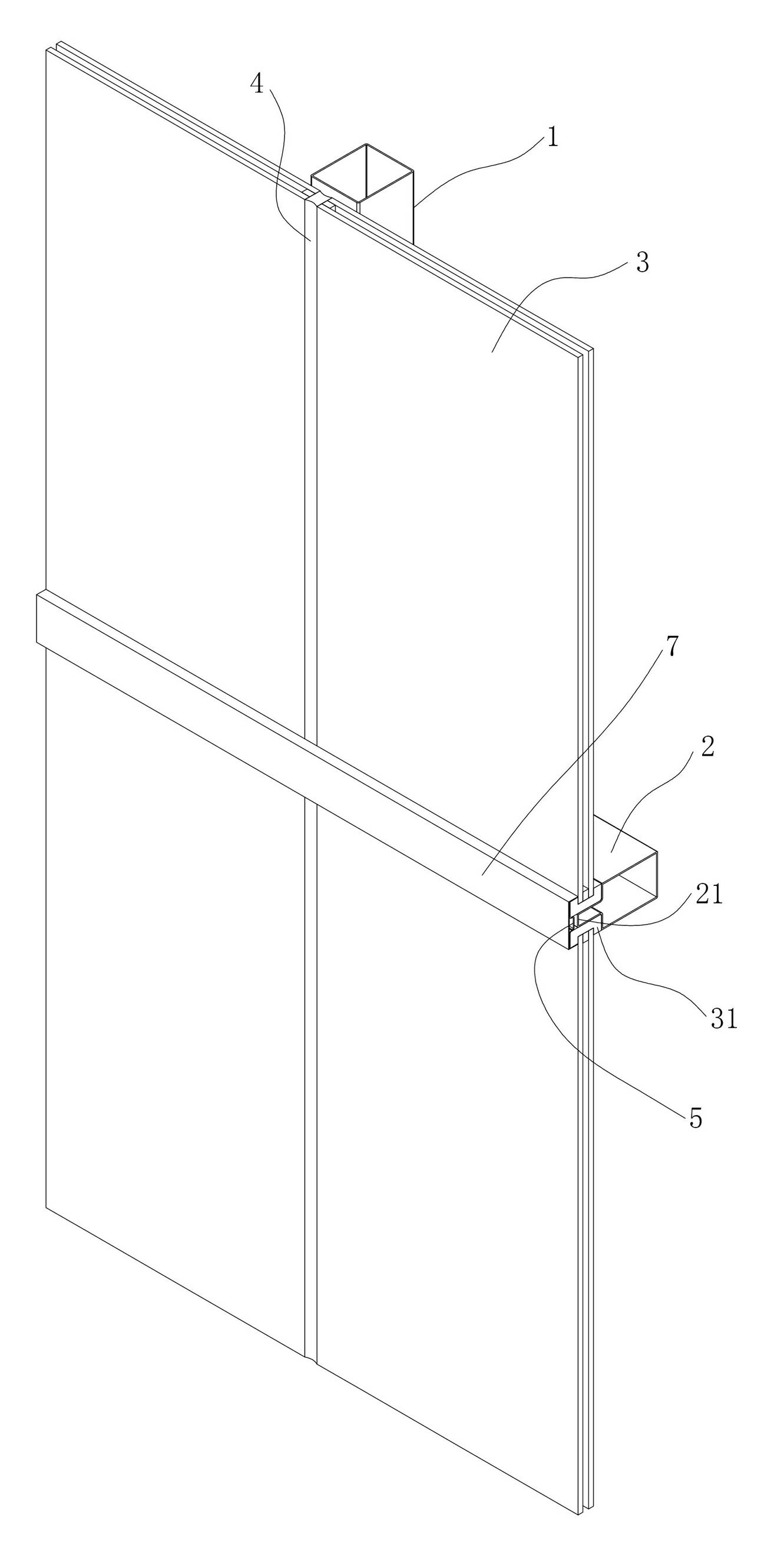

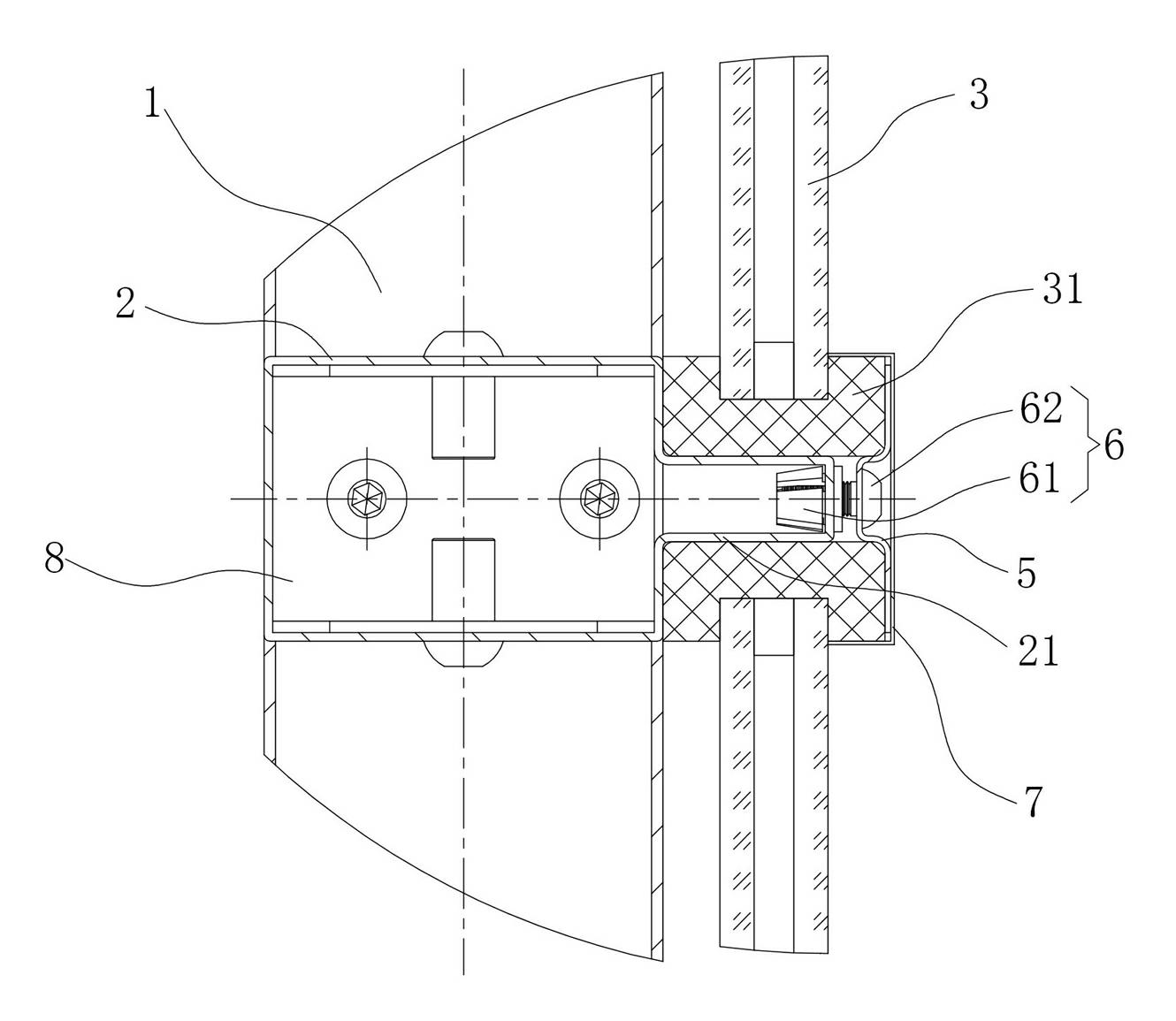

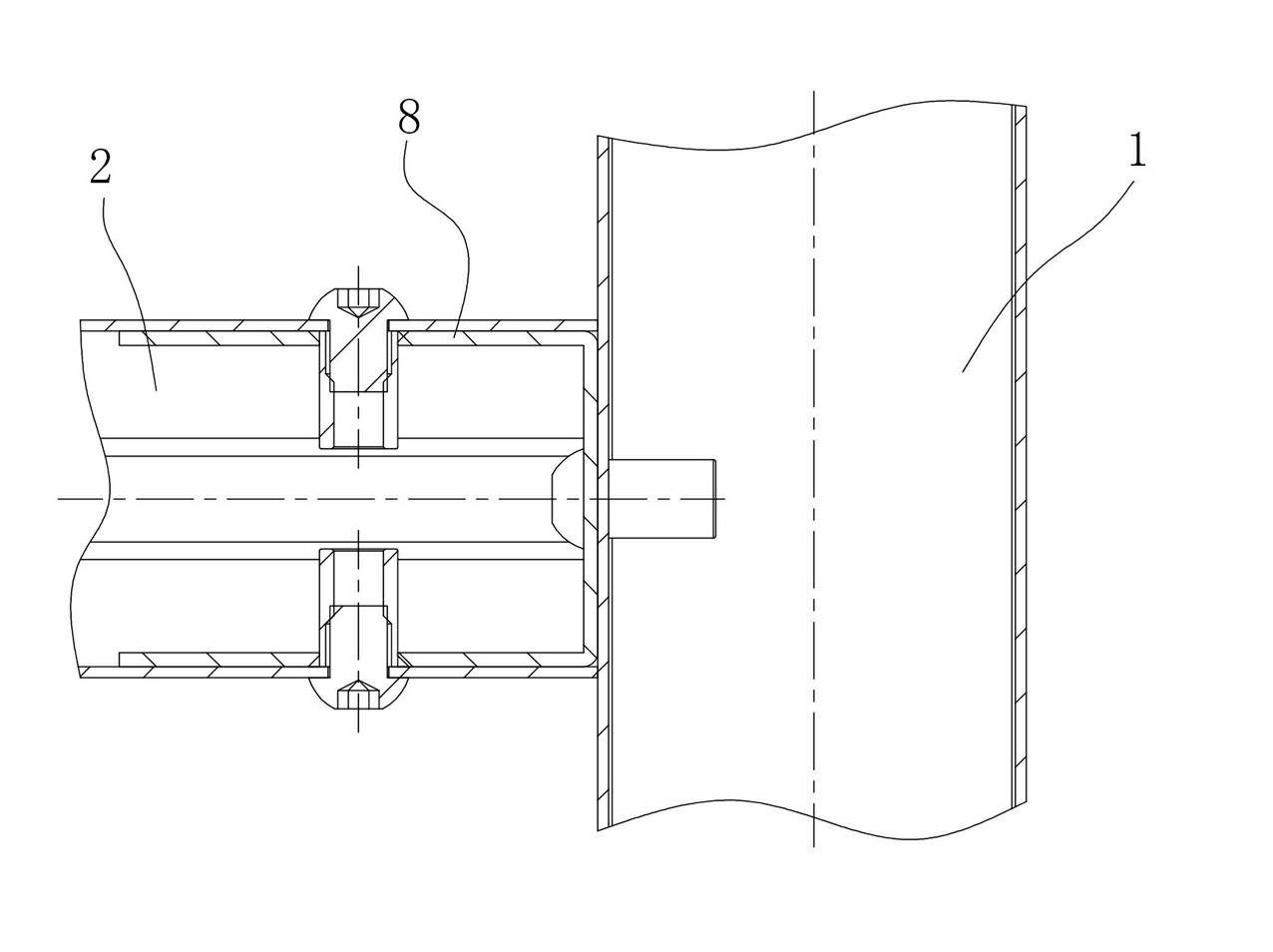

[0020] Figure 1 to Figure 3 It shows an embodiment of a thermal insulation curtain wall of the present invention, the curtain wall includes a vertical keel 1, a horizontal keel 2, several thermal insulation curtain wall panels 3 and in-wall fasteners arranged on the building wall, the vertical keel 1 passes through the The wall fasteners are fixed on the building wall, the horizontal keel 2 is connected between the adjacent vertical keels 1, the upper and lower ends of the thermal insulation curtain wall panel 3 are offset by the upper and lower horizontal keel 2 through the thermal insulation strip 31, and the upper and lower two Adjacent heat insulating rubber strips 31 of the heat insulating curtain wall panel 3 are compressed by a gland 5, and the gland 5 is connected and fixed to the transverse keel 2, which avoids direct exposure of the metal keel to the outdoor air and greatly improves the insulation of the heat insulating curtain wall. Thermal insulation effect and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com