Hollow laminated glass assembly for photovoltaic curtain wall and manufacturing method thereof

A laminated glass and hollow technology, which is applied in the field of hollow laminated glass components for photovoltaic curtain walls and its manufacturing, can solve the problems of frost and condensation, high cooling energy consumption, large thermal conductivity, etc., and achieve good sealing effect and good sound insulation Effect, the effect of excellent thermal insulation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The structure and manufacturing method of the laminated glass assembly for photovoltaic curtain wall of the present invention will be further described through specific examples below.

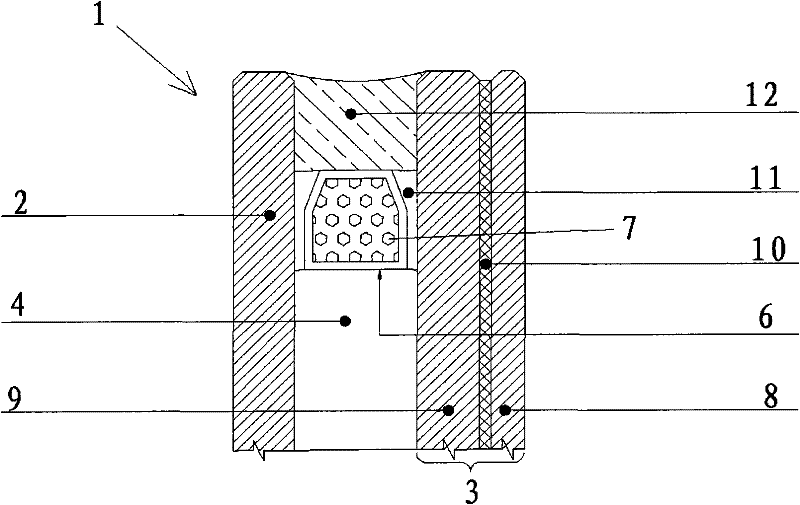

[0061] figure 1 It is a schematic side view of the laminated glass assembly structure for photovoltaic curtain wall according to the present invention. Such as figure 1 As shown, the hollow laminated glass assembly represented by the reference numeral 1 as a whole includes: a silicon-based thin-film photovoltaic cell panel 3 as a double-glass laminated outer glass; an inner glass 2; a photovoltaic junction box 5 (see figure 2 and 3 ); and a hollow layer 4 is formed between the photovoltaic cell panel 3 and the inner sheet glass 2; the aluminum spacer 6 packaged with a desiccant 7 is bonded together with the photovoltaic cell panel 3 and the inner sheet glass 2 in the hollow layer 4; The hollow laminated glass assembly 1 has the function of heat preservation. The aluminum spacer 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com