Independent pitch variable system for proportional valve-controlled hydraulic motor

An independent pitch, hydraulic motor technology, applied in the control of wind turbines, wind power generation, wind turbines, etc., can solve the problems of poor maintainability, complex control mechanism, etc., and achieve high torque, high control accuracy, and easy synchronous control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

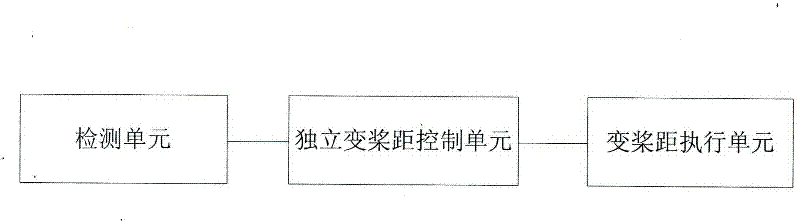

[0026] see figure 1 , the proportional valve-controlled hydraulic motor independent pitch control system in this embodiment includes a detection unit, an independent pitch control unit and a pitch execution unit:

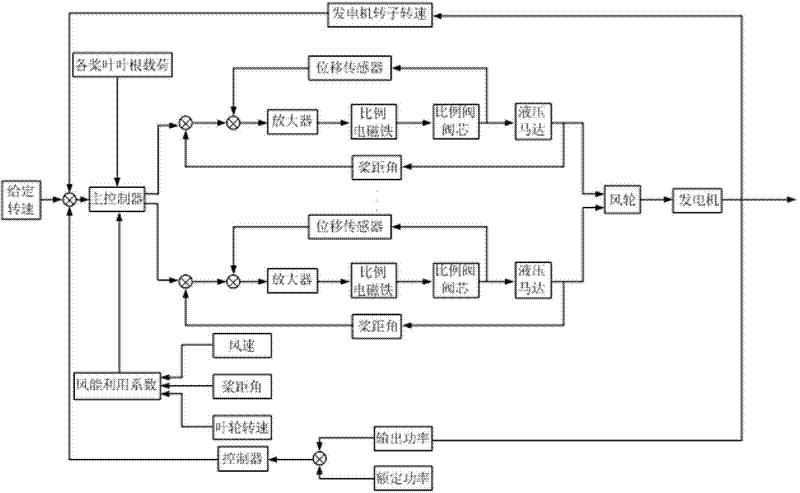

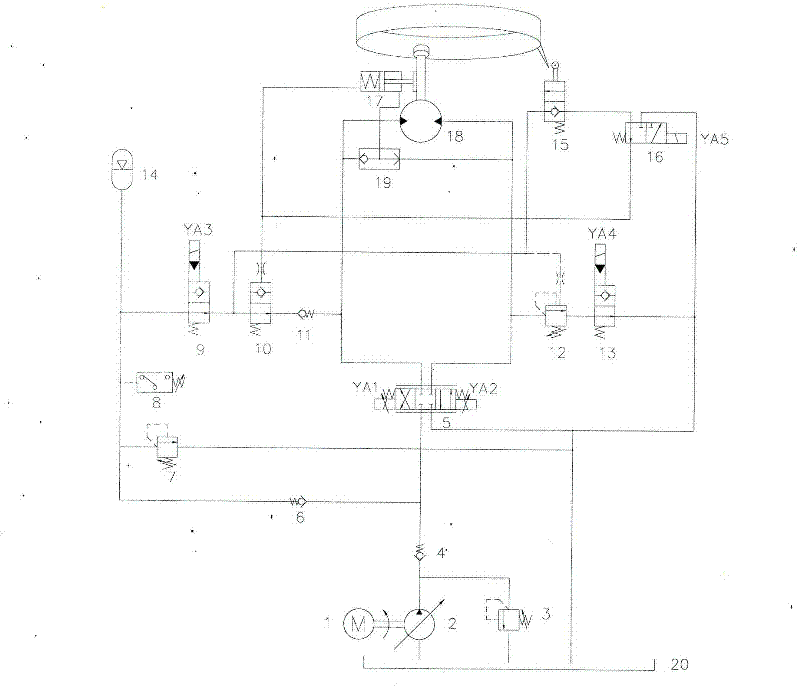

[0027] The detection unit is used to detect the pitch angle of the blade, the rotational speed of the wind rotor and the rotational speed of the generator rotor, and specifically includes an anemometer, an angular velocity sensor, a rotary encoder and a torque sensor. The anemometer is used to detect the wind speed signal; the angular velocity sensor is used to detect the generator rotor speed and the wind wheel speed; the rotary encoder is used to detect the spindle angle of the hydraulic motor in the proportional valve-controlled hydraulic system; the The torque sensor is used to detect the torque of the main shaft of the generator, and the angular velocity sensor and the torque sensor can realize the detection of the output power of the generator.

[0028] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com