Liquid conveying system

A delivery system and liquid input technology, which is applied in the direction of non-variable pumps, pump devices, machines/engines, etc., can solve the problems of equipment efficiency reduction, waste of electric energy, mixed oil and gas transmission, etc., and achieve strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

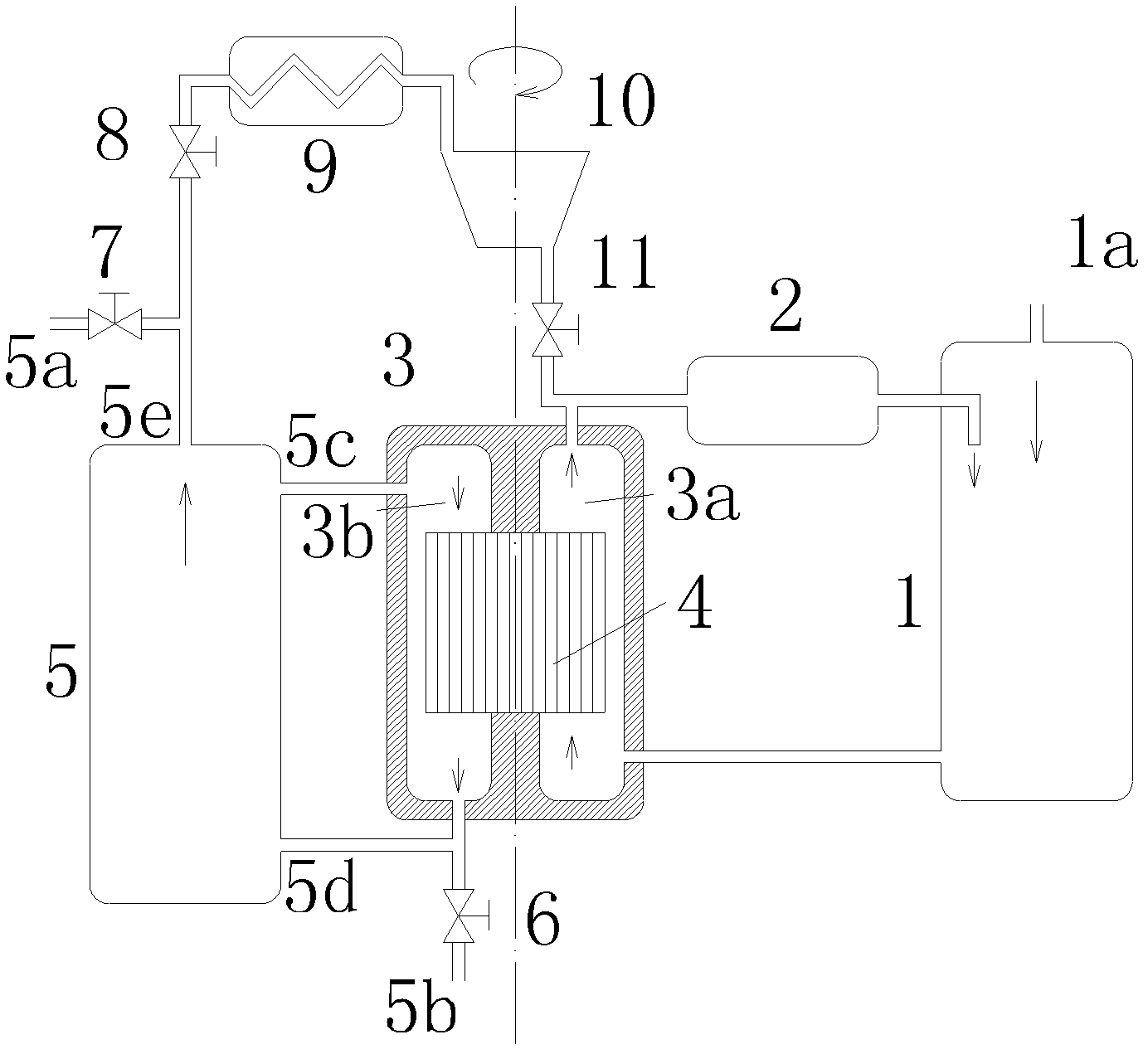

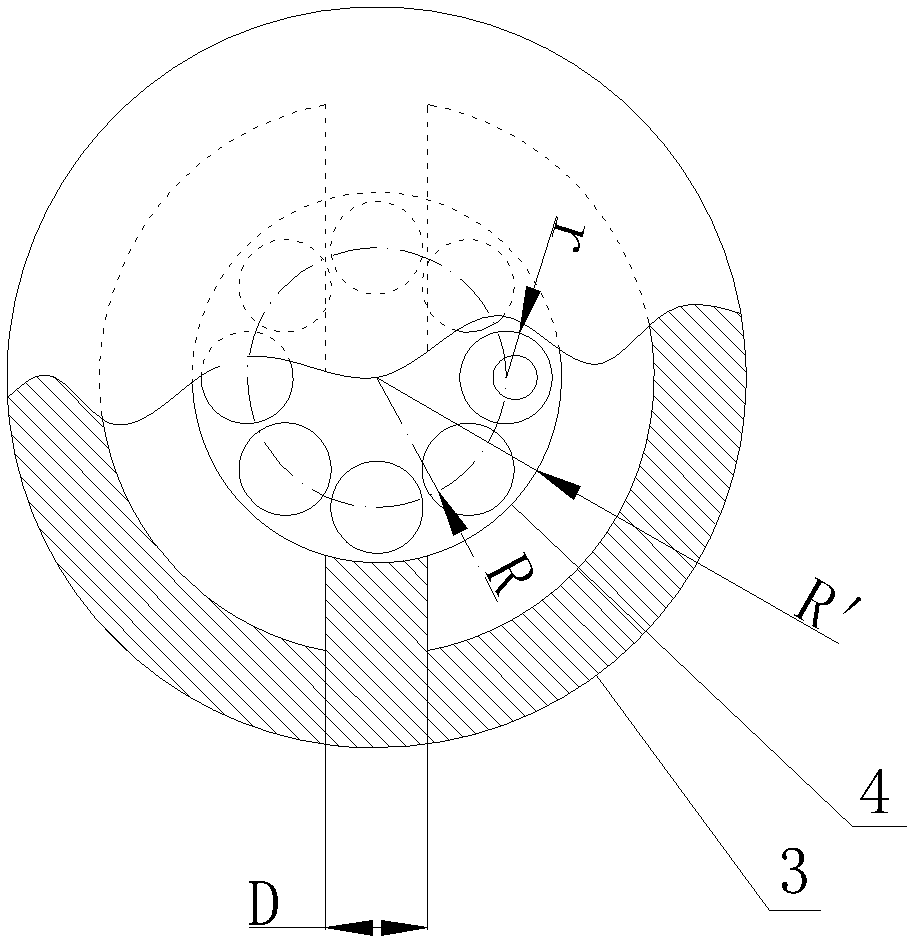

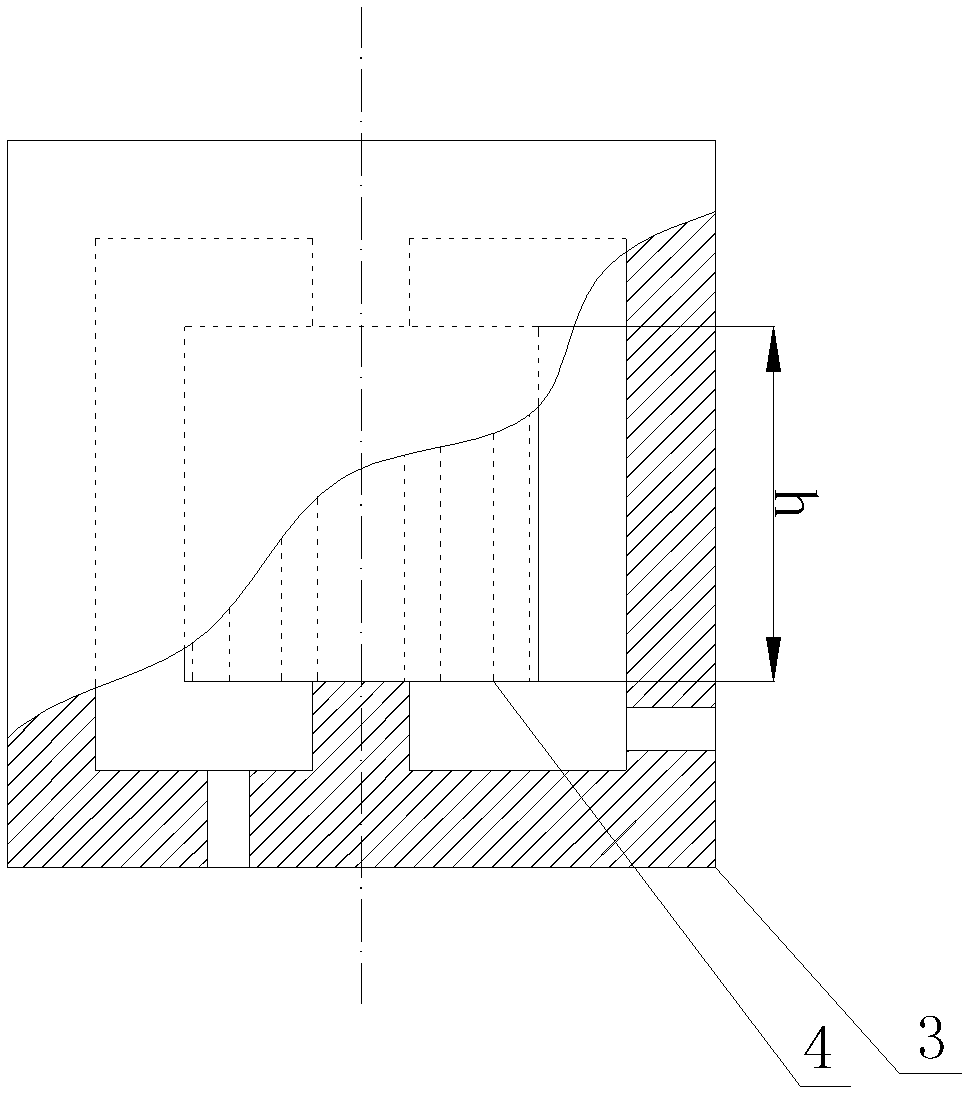

[0034] Such as figure 1 As shown, a liquid delivery system includes a liquid storage tank 1, a condenser 2, a stator 3, a rotor 4, a high pressure generator 5, a first control valve 6, a second control valve 7, a third control valve 8, and a superheater 9. Expander 10, fourth control valve 11. The top of the liquid storage tank 1 has a liquid input port 1a, the bottom of the high-pressure generator 5 has a liquid output port 5b, and the top has a gas outlet 5c and a top outlet 5e. The high-pressure generator 5 is used to vaporize the liquid. The stator 3 has a high-pressure chamber 3b and a low-pressure chamber 3a isolated from each other; wherein, the bottom and top of the high-pressure chamber 3b communicate with the bottom liquid outlet 5d and the gas outlet 5c of the high-pressure generator 5 respectively, and the bottom of the low-pressure chamber 3a communicates with the liquid storage tank 1 is communicated with the bottom, and the top of the low-pressure chamber 3a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com