SOI (silicon on insulator) based electrooptical modulator based on symmetrical and vertical grating coupling

An electro-optical modulator and vertical coupling technology, which is applied in instruments, optics, nonlinear optics, etc., can solve problems such as large size and insertion loss, process and temperature sensitivity, and large optical bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

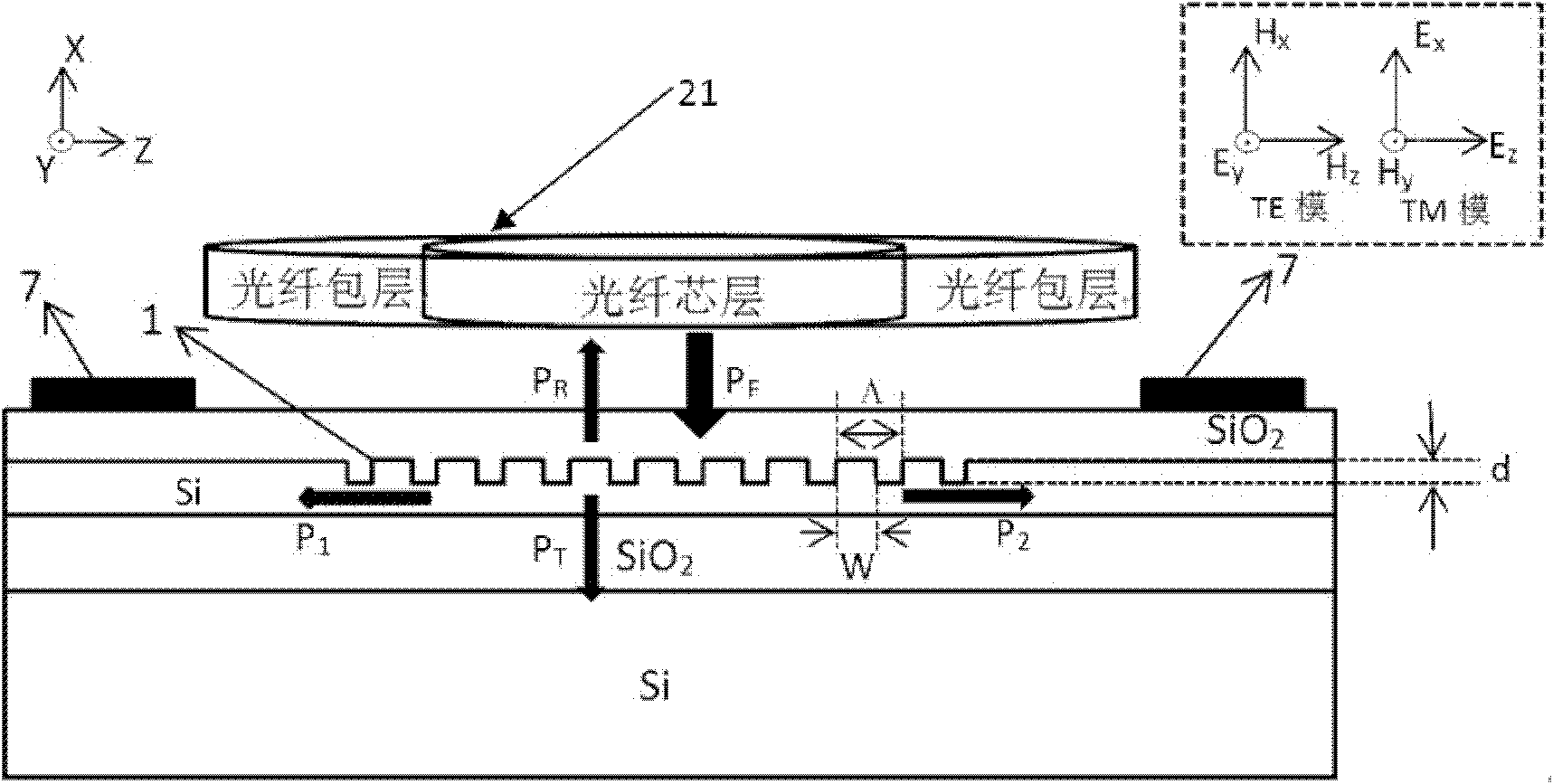

[0021] Since the present invention is a silicon-based electro-optical modulator based on SOI substrate material design, for different buried oxide layer thicknesses and top layer silicon thicknesses, the corresponding optimal design is also different to achieve functional requirements. Therefore, for convenience of description, the substrate of the present invention The bottom material defaults to specific implementation parameters, that is, the thickness of the buried oxide layer is 2 μm, and the thickness of the top silicon layer is 220 nm.

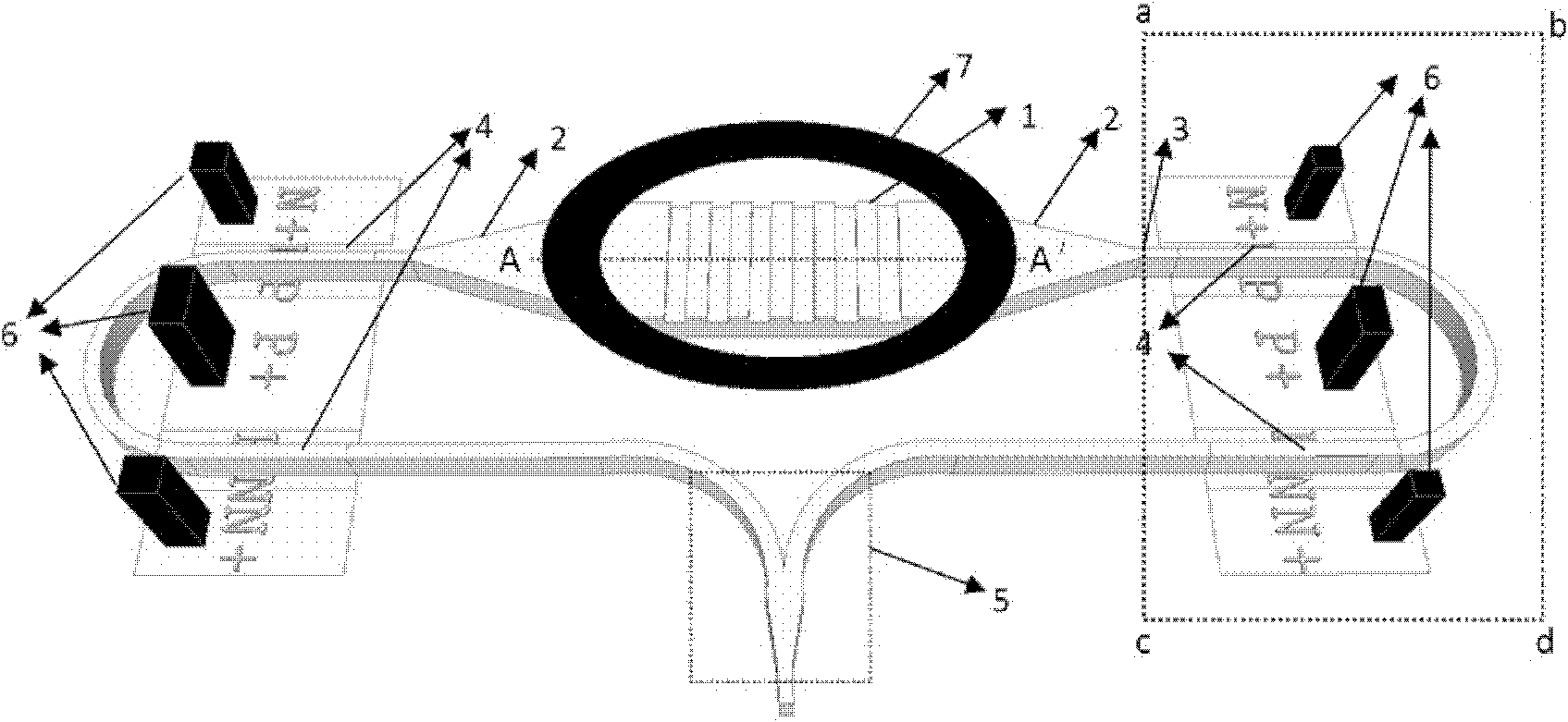

[0022] see figure 1 and figure 2 , the present invention provides an SOI-based electro-optic modulator based on symmetrical vertical grating coupling, comprising:

[0023] A symmetrical vertical coupling grating 1, as SOI-based electro-optic modulator and optical fiber 21 ( figure 2 ) interface or coupler and 3-dB optical beam splitter at the input of the SOI-based electro-optic modulator;

[0024] Two mode converters 2, as the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com