Pressing suction element with powder falling prevention device and preparation method for suction element

A component and anti-dropping technology, which is applied in the field of electric vacuum getter element preparation, can solve the problems of inability to meet the requirements of electric vacuum devices, decrease in strength performance of elements, decrease in element getter performance, etc., and achieve excellent getter performance and low forming pressure. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

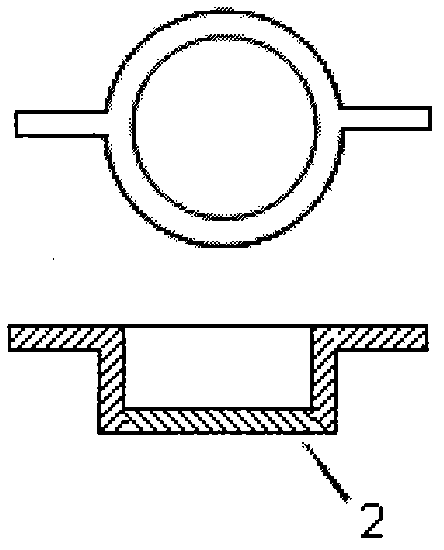

[0048] Such as figure 2 As shown, take a 0.15mm thick pure nickel sheet and punch it into a dish-shaped container 2 with an outer edge. The diameter of the outer edge is Φ12mm, the diameter of the container mouth is Φ10mm, and the depth of the container is 2mm. The length of ° is 5mm and the width is two support bars of 1.5mm.

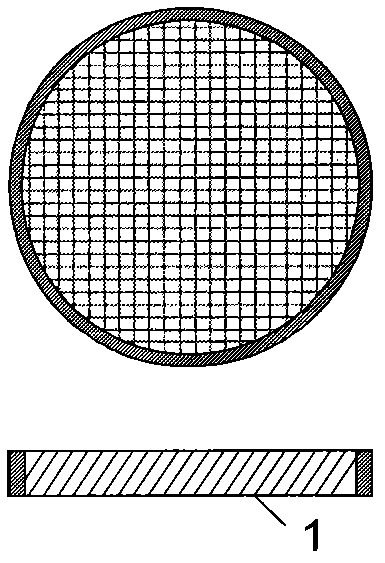

[0049] Such as figure 1 As shown, a pure molybdenum sheet with a thickness of 0.02mm is selected, and the pure molybdenum porous net is prepared into a disc shape of Φ11.6mm. The edge of the disc is a metal ring with a width of 0.8mm, and the diameter of the porous net 1 is Φ10mm. The pore size is 30 μm.

[0050] Binder preparation: Dissolve 100g of Canadian gum in 1000ml of absolute ethanol, and place it for 12h to prepare a thick binder solution.

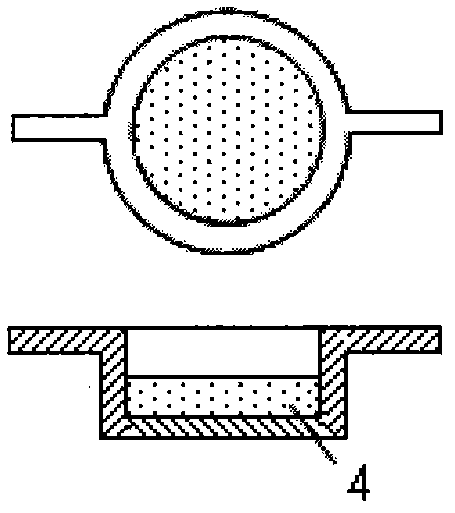

[0051] Such as image 3 As shown, take -200 mesh to +300 mesh ZrVFe alloy powder, mix it with the binder solution at a weight ratio of 9:1 to prepare a getter alloy powder mixed with a binder, and add...

Embodiment 2

[0055] The operating method and process conditions are basically the same as those in Example 1, except that the only difference is that the particle size of the ZrVFe powder used in Example 2 is -300~+400 mesh. The air-absorbing element with the anti-powder dropping device prepared in Example 2 was tested for air-absorbing performance according to national standards. The activation temperature was 500°C, and the holding time was 10 minutes. The air-absorbing performance was tested, and the air-absorbing rate at room temperature was S 10 =1353ml / s·g, the total amount of inspiration in 30min is 1083Pa·ml / g. Vibration test on the suction element with a frequency of 60Hz, an amplitude of 1.2mm, and a time of 60min. After vibration, check under a magnifying glass of 5 times that there is no powder falling off.

Embodiment 3

[0057] The operating method and process conditions are basically the same as those in Example 1, except that the only difference is that the average pore diameter of the porous mesh used in Example 3 is 40 μm. The air-absorbing element with the anti-powder dropping device prepared in Example 3 was tested for air-absorbing performance according to national standards. The activation temperature was 500°C, and the holding time was 10 minutes. The air-absorbing performance was tested, and the air-absorbing rate at room temperature was S 10 =1246ml / s·g, the total amount of inhalation in 30min is 1027Pa·ml / g. Vibration test on the suction element with a frequency of 60Hz, an amplitude of 1.2mm, and a time of 60min. After vibration, check under a magnifying glass of 5 times that there is no powder falling off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap