Large-scale indium column generation method for infrared focal plane detector

An infrared focal plane and growth method technology, which is applied in the field of indium column growth of large-scale infrared focal plane detectors, can solve the problems of blind elements in the detector and easy residues in the indium column, and achieve good shape consistency and improve connectivity Rate, reduce the effect of blind rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

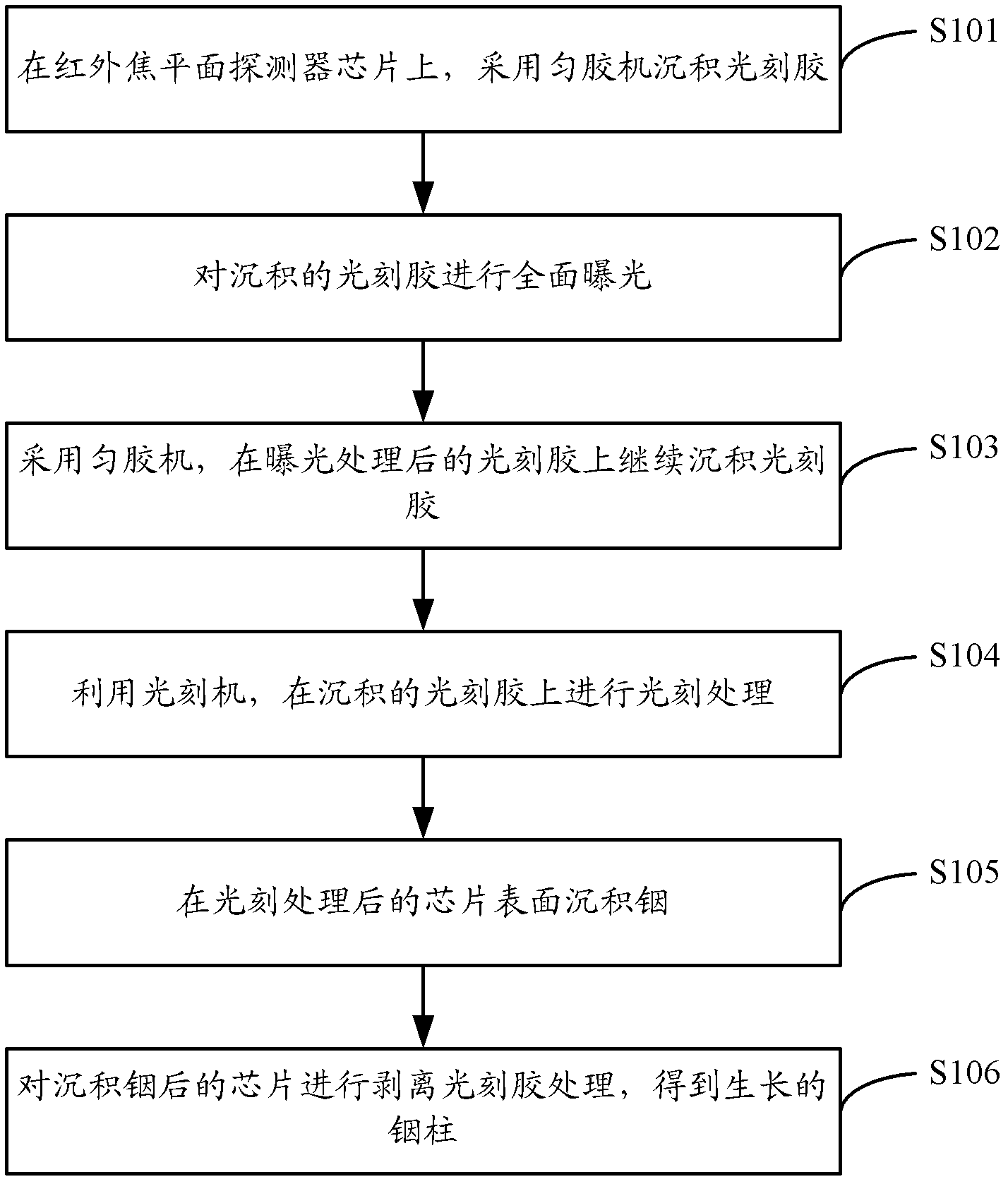

[0033] An embodiment of the present invention provides a large-scale infrared focal plane detector indium column growth method, such as figure 1 shown, including the following steps:

[0034] Step S101, depositing photoresist on the infrared focal plane detector chip by using a coater;

[0035] In this step, the photoresist is deposited with a thickness of 10-20 microns.

[0036] Step S102, fully exposing the deposited photoresist;

[0037] In this step, the exposure time for full exposure is 15-30s;

[0038] In this step, the method of fully exposing the deposited photoresist is preferably but not limited to: placing the chip on which the photoresist is deposited on a photolithography machine, and using the photolithography machine to expose the coated photoresist without installing a photoresist plate. The photoresist is exposed to light.

[0039] Step S103, using a coater to continue depositing photoresist on the exposed photoresist;

[0040] In this step, the photores...

Embodiment 2

[0048] An embodiment of the present invention provides a method for growing an indium column for a large-scale infrared focal plane detector, which is a specific implementation of the method described in Embodiment 1. The method described in this embodiment includes:

[0049] Step 1, on the infrared focal plane detector chip, use a homogenizer to deposit a photoresist with a thickness of 12 μm; the chip for depositing the photoresist is as follows figure 2 As shown, "1" in the figure is the photoresist.

[0050] In step 2, the chip deposited with photoresist is placed on the exposure table of the exposure machine, and the photoresist is exposed by using the photolithography machine without a photoresist plate; in this embodiment, the exposure time is 20s.

[0051] Step 3: Deposit a photoresist with a thickness of 12 μm on the chip by using a homogenizer; the chip where the photoresist is deposited again is as follows image 3 As shown, "2" in the figure represents the photor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com