Highly efficiently luminescent electroluminescent device

An electroluminescent device, high-efficiency technology, applied in the direction of electro-solid devices, electrical components, semiconductor devices, etc., can solve the problems of equipment short circuit, complex, unable to effectively increase the output of light, etc., to improve the efficiency of light output and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

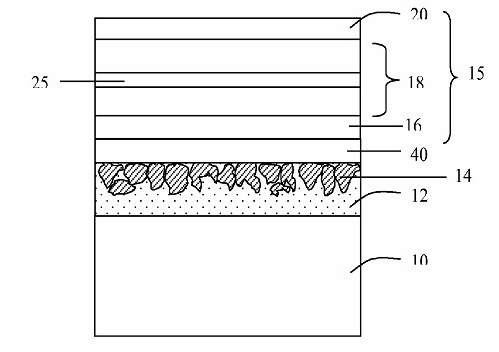

[0081] like figure 1 As shown, the electroluminescent device of this embodiment includes a transparent substrate 10, a light-enhancing structure, and an LED unit 15. The LED unit 15 includes a transparent electrode layer 16, a light-emitting element 18 with a light-emitting layer 25, and a reflective electrode layer 20. The structure includes a light scattering layer 14 with a layer of high refractive index particles, a surface smoothing layer 40 with a high refractive index, and a protective layer 12 .

Embodiment 2

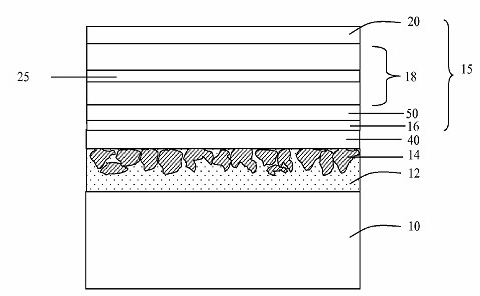

[0083] like figure 2 As shown, the electroluminescent device of this embodiment includes a transparent substrate 10, a light-enhancing structure, and an LED unit 15. The LED unit 15 includes a transparent electrode layer 16, an anti-short-circuit layer 50, a light-emitting element 18 with a light-emitting layer 25, and a reflection The electrode layer 20 has a light-enhancing structure including a light-scattering layer 14 with a layer of high-refractive-index particles, a surface-smoothing layer 40 with a high-refractive index, and a protective layer 12 .

Embodiment 3

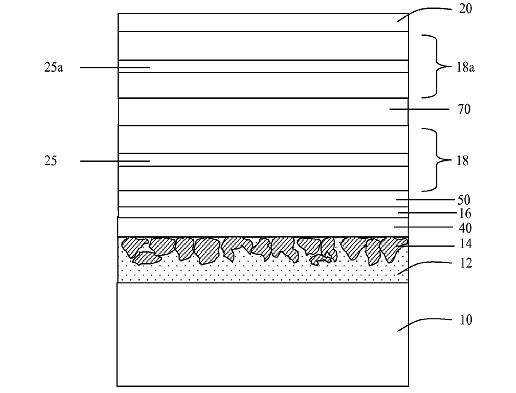

[0085] like image 3 As shown, the electroluminescent device of this embodiment includes a transparent substrate 10, a light-enhancing structure and an LED unit 15. The LED unit 15 includes a transparent electrode layer 16, an anti-short-circuit layer 50, a light-emitting element 18 with a light-emitting layer 25, a connection The unit 70, the light emitting element 18a with a light emitting layer 25a and the reflective electrode layer 20, the light enhancement structure includes a light scattering layer 14 with a layer of high refractive index particles, a surface smoothing layer 40 with a high refractive index and a protective layer 12.

[0086] The connecting units enable electrons of two adjacent organic light-emitting units to be injected into the electron transport layer, and holes to be injected into the hole transport layer. Preferably, the connecting unit is transparent and is connected in series on the OLED. Also preferably, the connection unit does not have much in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com