Structure for connecting braided coaxial cable and connector to realize low passive inter-modulation performance

A coaxial cable, passive intermodulation technology, applied in the direction of conductive connection, connection where permanent deformation works, connection, etc. Suitable for large-scale application, extended braided cable application, low passive intermodulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

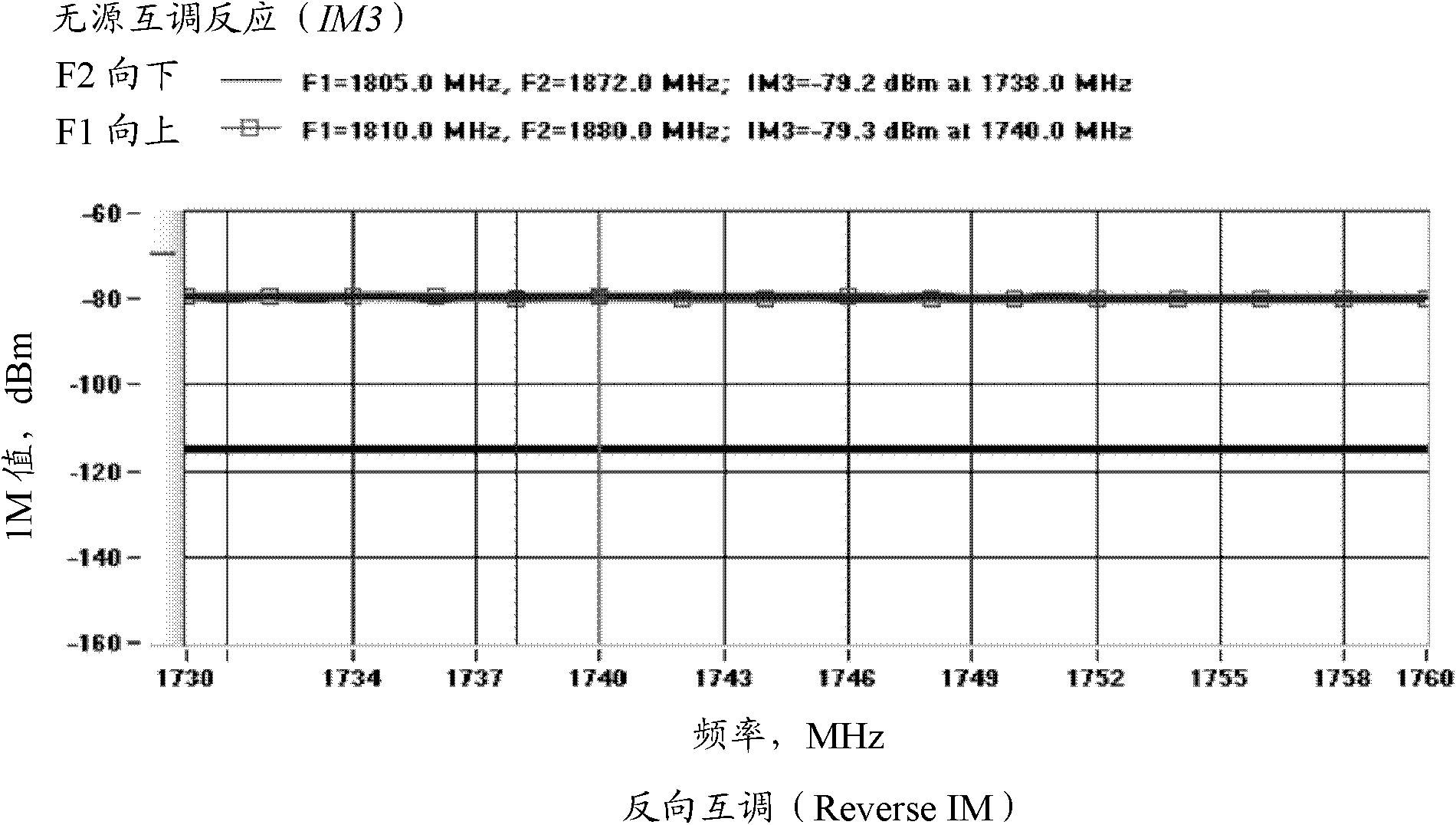

[0029] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. In this case, the same components are provided with the same reference numerals. Regarding the PIM test method, in accordance with IEC-62037-6, test 15ea cables with soldered or crimped connectors at the ends to run a complete test, fully compliant with IEC-61169-1 and IEC60096-1 general tests for RF connectors and cables Require.

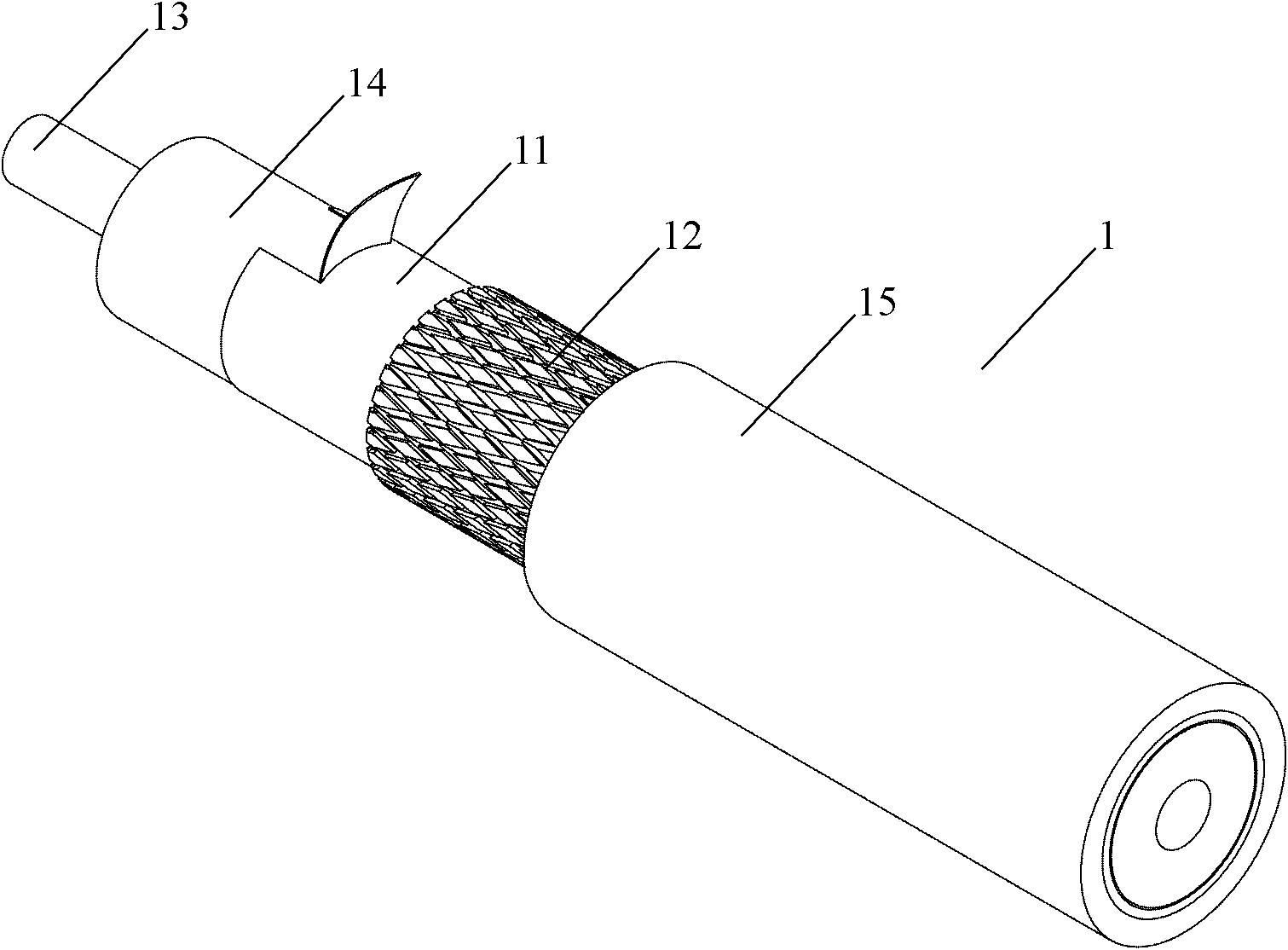

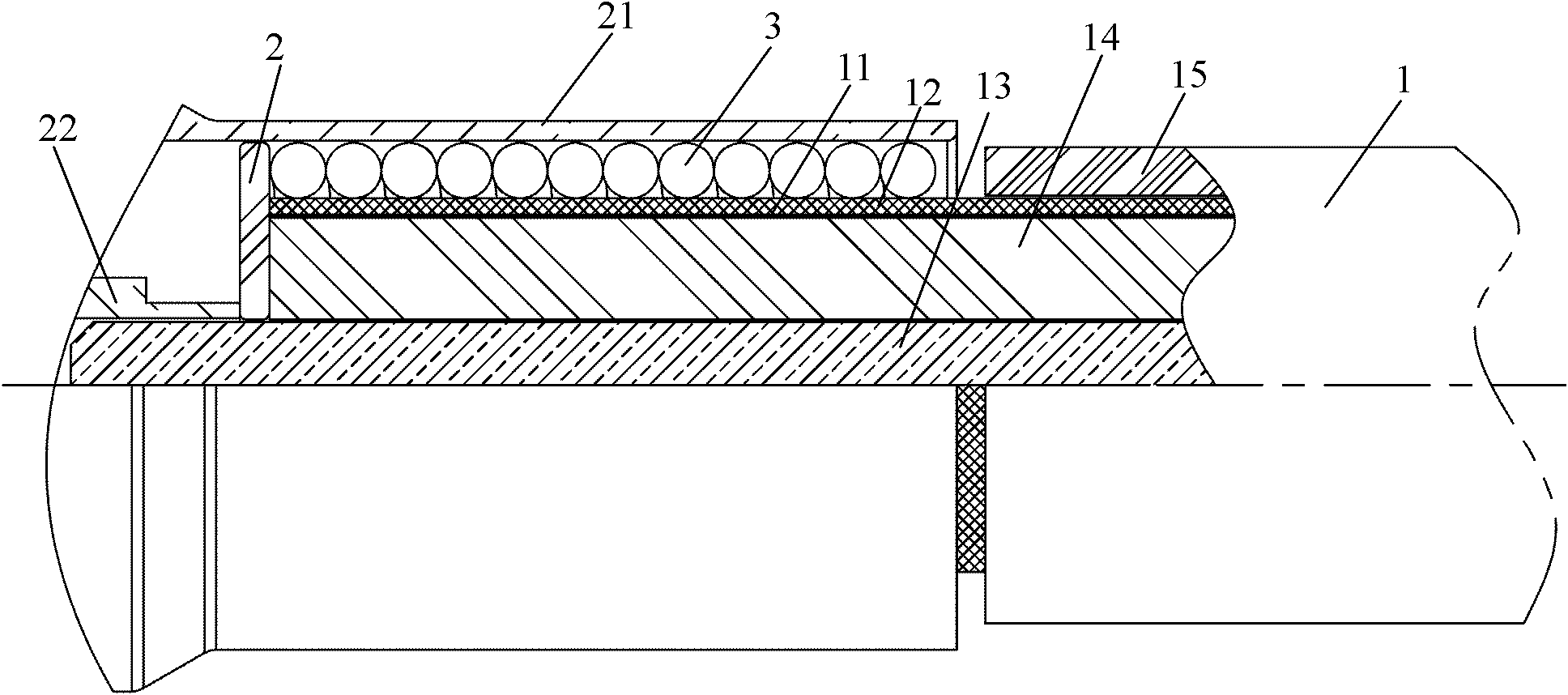

[0030] See image 3 as shown, image 3 Shown is a specific embodiment of the connection structure between the braided coaxial cable and the connector to achieve low passive intermodulation performance of the present invention, including a braided coaxial cable 1 and a connector 2, the braided coaxial cable 1 has an aluminum foil Layer 11 and braided layer 12, the connector 2 has a connector outer conductor 21, the aluminum foil layer 11 is a single-layer aluminum foil, and the connection structure between the bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com