Lubricating varnish for coating a metal component or applied to a metal component

A metal component, coating technology, applied in the field of lubricating paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

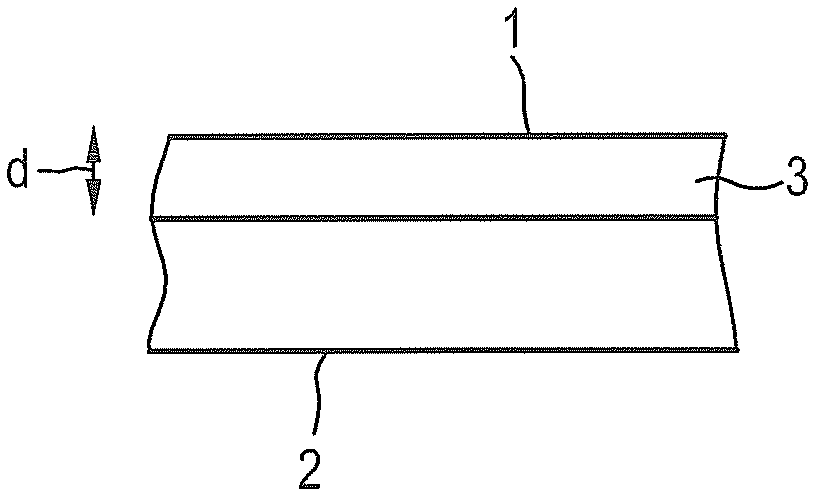

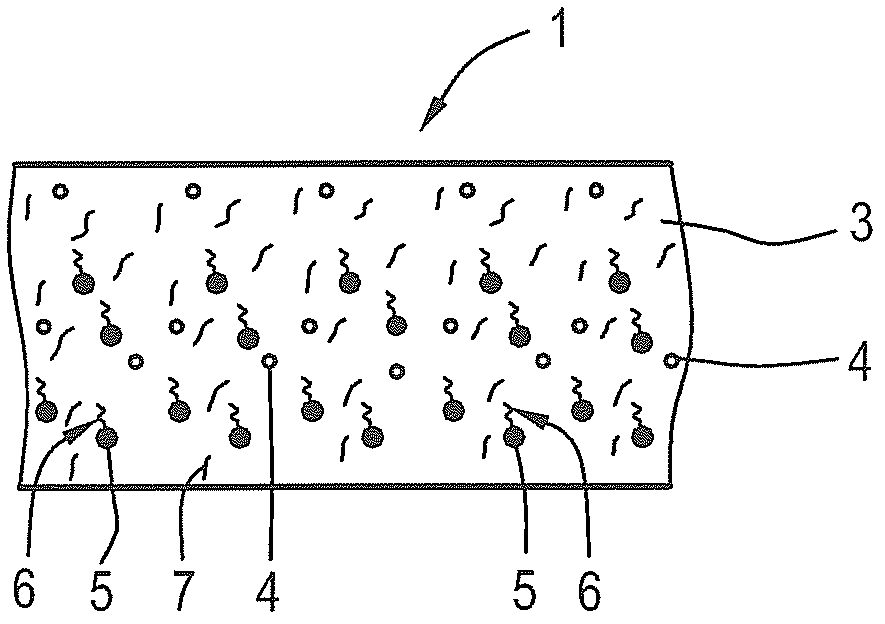

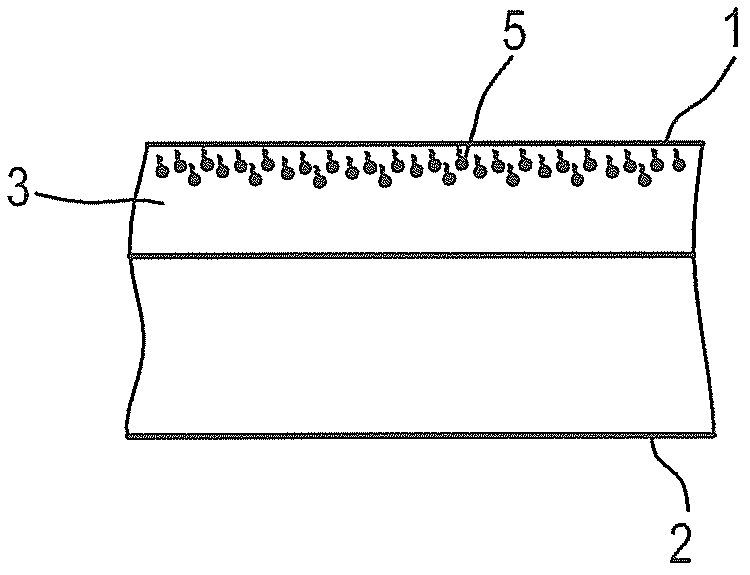

[0089] figure 1 The lubricant varnish 1 according to the invention is shown in the form of a coating on a component 2 , in particular a metal component. Here, the component 2 does not have to have a flat surface, but can also have any shape, for example a curved or angled shape. Furthermore, the component 2 can be three-dimensionally structured on its surface. For example, a certain roughness can be intentionally provided so that the lubricating paint 1 adheres better to the surface of the component 2 . Between the component 2 and the lubricant varnish 1 there is a relatively stable, preferably insoluble composite formed by the matrix 3 of the hardened lubricant varnish 1 . Hardening of the matrix 3 can take place, for example, by heating or UV radiation, NIR radiation, IR radiation or particle radiation. In this embodiment, the layer thickness of the lubricant varnish 1 is approximately 25 μm. The tribological properties of the component 2 are significantly improved by ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com