Method for preparing hollow polymer microcapsules based on millifluidics device

A technology of polymers and microcapsules, applied in the field of preparation of hollow polymer microcapsules, can solve the problems of wide diameter distribution of microcapsules, low operating costs, microcapsule bubbles, etc., and achieves low cost, easy control, and reduced solution volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

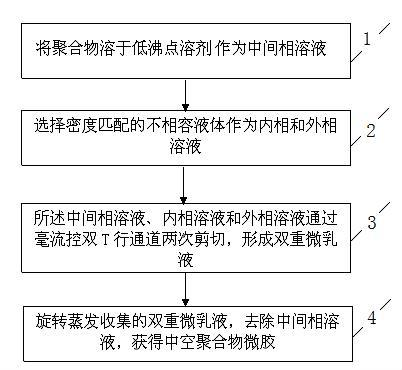

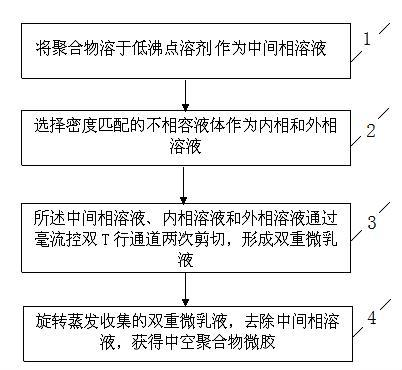

[0039] see figure 2 Shown, a kind of preparation method based on millifluidic hollow polymer microcapsules is characterized in that, comprises the following steps:

[0040] 1) Dissolving the polymer in a low boiling point solvent as a mesophase solution;

[0041] 2) Select incompatible liquids with matching densities as the inner and outer phase solutions;

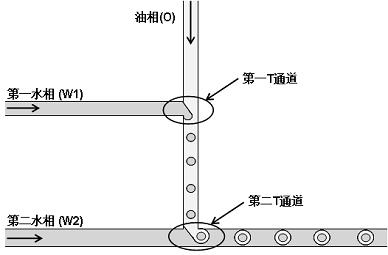

[0042] 3) The intermediate phase solution, the internal phase solution and the external phase solution are sheared twice through the millifluidic double T-line channel to form a double microemulsion;

[0043] 4) The collected double microemulsion was rotary evaporated to remove the mesophase solution to obtain hollow polymer microcapsules.

[0044] Further, in step 1, a surfactant may also be added.

[0045] Implementation column 1:

[0046] Preparation of hollow polyacrylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com