Preparation method of porous composite material for reducing harmful substances in flue gas

A technology of porous composite materials and harmful components, applied in chemical instruments and methods, tobacco, smoke oil filter elements, etc., can solve the problems of increasing the cost of cigarettes, surface deposition and inactivation, etc., and achieve high reaction selectivity, easy-to-obtain products, The process is simple and easy to grasp the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Accurately measure tetraethyl orthosilicate: Fe(NO 3 ) 3 9H 2 O: Ce(NO 3 ) 3 ·6H 2 O: NaOH: cetyltrimethylammonium bromide: sodium laurate: water=1: 0.02: 0.02: 0.5: 0.2: 0.02: 70, stirred in the reactor for 3 hours to obtain a gelatinous mixture at 150 ℃ for 20-24 hours in a high-pressure reactor, and then adjust the pH of the reactant in the kettle to 8 with NaOH, then continue heating for 48 hours, and take out the reactant after cooling to room temperature. The reactants were washed with deionized water and dried, and then calcined at a high temperature of 600° C. for 3 hours, and the calcined products were pulverized and passed through a 150-mesh sieve to obtain the porous composite material.

Embodiment 2

[0024] Accurately measure tetraethyl orthosilicate: Fe(NO 3 ) 3 9H 2 O: Ce(NO 3 ) 3 ·6H 2 O: NaOH: cetyltrimethylammonium bromide: sodium laurate: water=1: 0.02: 0.02: 0.5: 0.2: 0.02: 70, stirred in the reactor for 1 hour, and obtained the gel-like mixture at 100 ℃ for 20-24 hours in a high-pressure reactor, then adjust the pH of the reactant in the kettle to 10 with NaOH, then continue heating for 2 days, and take out the reactant after cooling to room temperature. The obtained reactants were washed and dried, and then calcined at a high temperature of 500° C. for 8 hours, and the calcined products were pulverized and passed through a 200-mesh sieve to obtain the porous composite material.

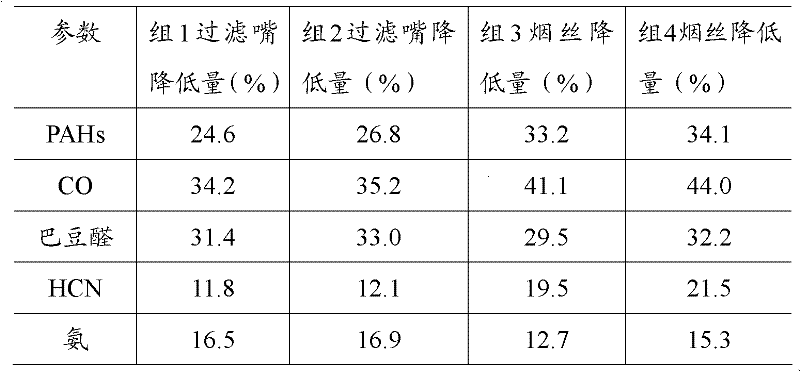

[0025] Choose 10 filter tips with the porous composite material added and 10 cigarettes with the porous composite material of Example 2 added to the shredded tobacco. Among them, 5 add 0.5% of the porous composite material based on the total weight of tobacco leaves in the filter ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com