High-temperature fuel cell stack, fuel cell system, and system control method

A high-temperature fuel cell and fuel technology, which is applied in the field of fuel cell systems and system control, and high-temperature fuel cell stacks, can solve the problems of anode catalyst poisoning, deterioration of battery stability, deterioration of battery performance, etc., to achieve stable operating conditions, The effect of reducing the decay rate and increasing the reformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

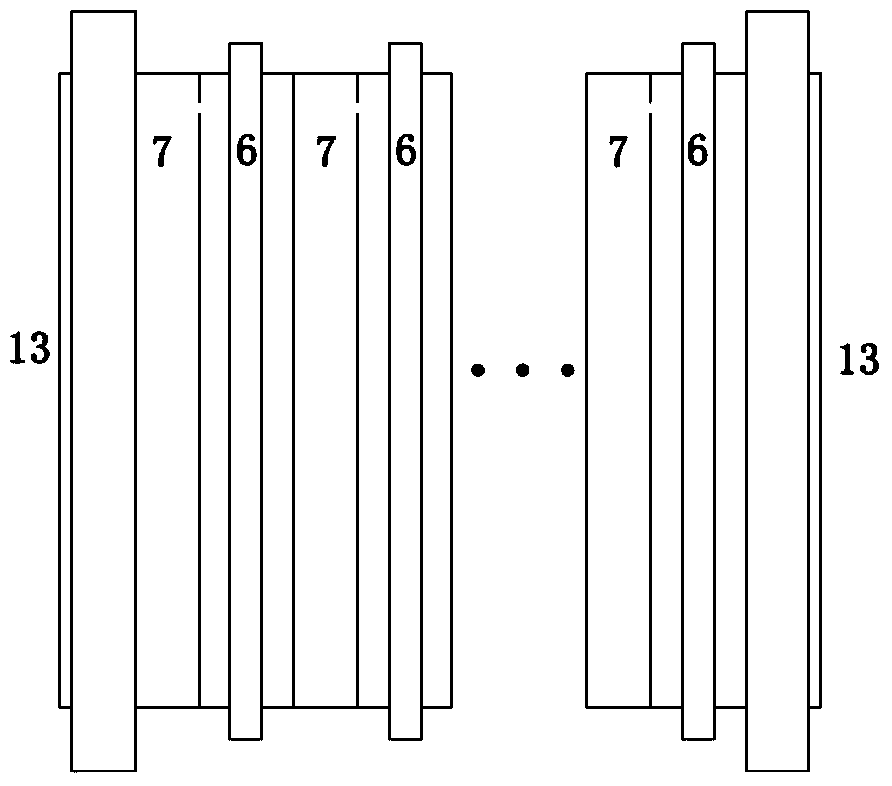

[0038] The first specific embodiment includes: fuel pretreatment device, fuel pretreatment; high temperature fuel cell stack, after the pretreated fuel undergoes water vapor shift reaction in the high temperature fuel cell stack, it is transported to the anode of the high temperature fuel cell stack for Catalytic reaction to generate electric energy; fuel storage and supply unit, providing the reaction fuel to the high-temperature fuel cell stack, and air supply unit, providing air to the single cells and fuel processing units in the fuel cell stack, And auxiliary heating components for heating the high temperature fuel cell stack.

specific Embodiment approach 2

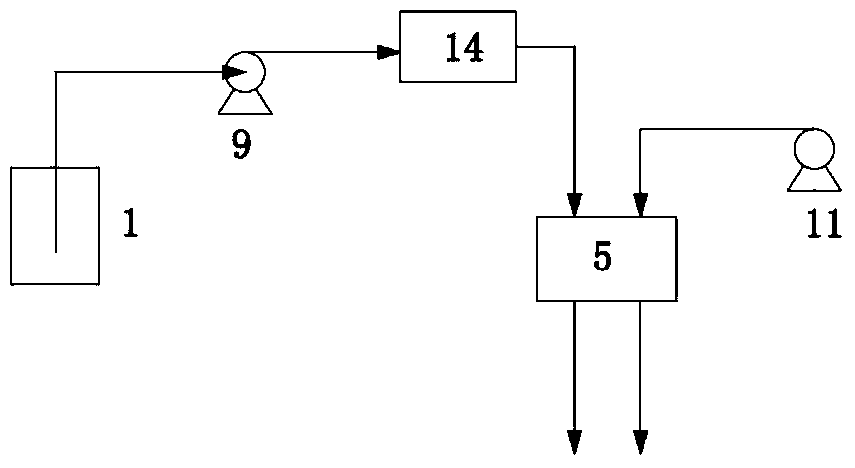

[0039] The second specific embodiment includes: fuel pretreatment device, fuel pretreatment; high-temperature fuel cell stack, reforming the pretreated fuel into anode fuel, and using the generated fuel to carry out catalytic reaction to generate electric energy; fuel storage and supply unit, The reaction fuel is provided to the high-temperature fuel cell stack, the air supply unit supplies air to the single cells and fuel processing units in the fuel cell stack, and the auxiliary heating component is used to heat the high-temperature fuel cell stack.

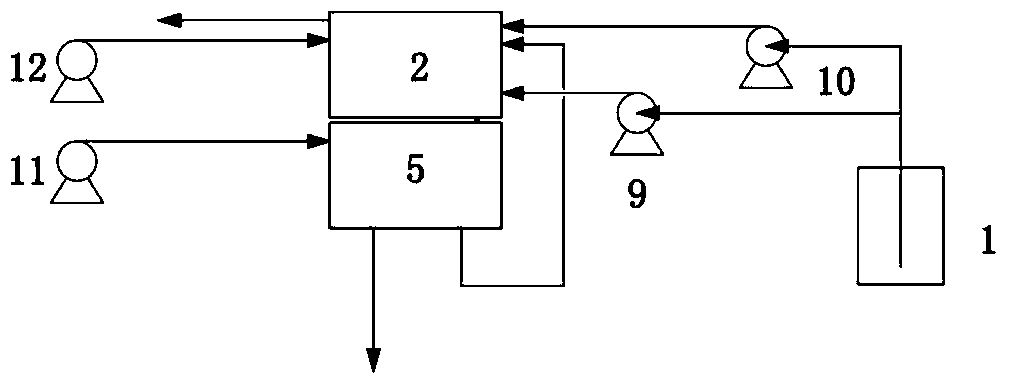

[0040] Specific implementation mode one:

[0041] The input port of the fuel reforming unit 3 of the fuel pretreatment device 2 communicates with the outlet of the fuel storage unit 1 through a pipeline, and a fuel supply unit 9 is arranged on the pipeline;

[0042] The output port of the fuel reforming unit 3 of the fuel pretreatment device 2 is close to the fuel processing unit 7 of the high-temperature fuel cell stack 5, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com