Thin film spray coating machine and thin film preparation method

A technology of spraying machine and thin film, which is applied in the direction of coating, spraying device, liquid spraying device, etc. It can solve the problems of affecting the quality of the film, changing the surface morphology of the film, damaging the film, etc., and achieves good film forming repeatability and is convenient for the laboratory. And small-scale industrial film production, good repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

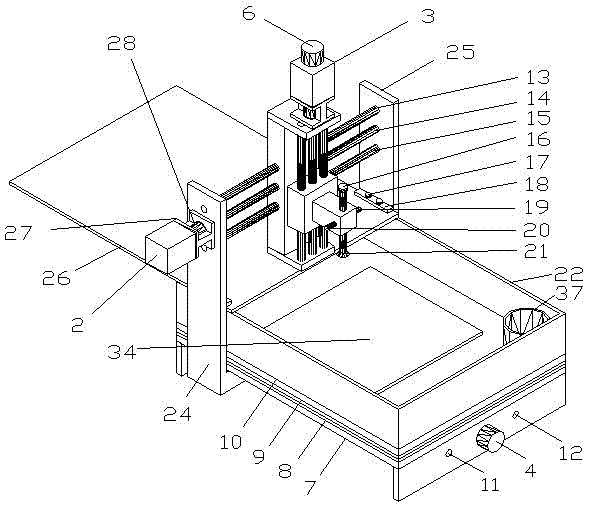

[0044] Such as Figure 3 to Figure 5 As shown, the film spraying machine involved in the present invention is mainly composed of a three-dimensional electric adjustment frame, a post-processing tank 22, a cover plate 26, and a controller 36. The first motor 1, the second motor 2 and the third motor 3 are controlled by the controller 36, so as to realize the movement of the nozzle 21 in three-dimensional space; the opening of the ultrasonic generator 23 and / or the electric heating jacket 39 is controlled by the controller 36; The opening and closing of the nozzle is controlled by the air solenoid valve 32 ; the temperature of the film-forming substrate 34 is controlled by the temperature sensor (not shown in the figure) and the electric heating plate 9 .

[0045] Such as Figure 5 As shown, the solution pipe interface 19 is connected to the solution bottle 31, one end of the air solenoid valve 32 is connected to the compressed air pipe interface 20, and the other end is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com