Turning tool and ball screw nut roller path machining method by using same

A processing method and technology of ball screw pair, which are applied in the accessories of tool holders, thread cutting tools, metal processing equipment, etc., can solve the problems of long production cycle and low processing efficiency, and achieve smoothness, improve processing efficiency, shorten the The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

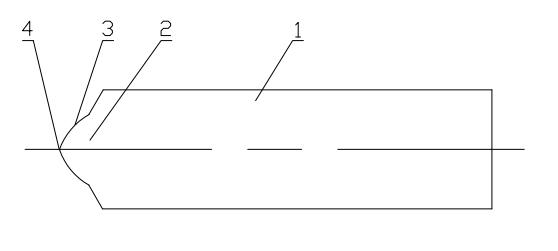

[0016] Depend on image 3 As shown, the forming turning tool includes a handle 1 and a cutter head 2, and the cutting edge 3 of the cutter head 2 includes two arcs, and the two arcs are connected at a common end 4, and the cutting edge of the forming turning tool 3 shapes with figure 2 The nut raceway tooth profile shown in .

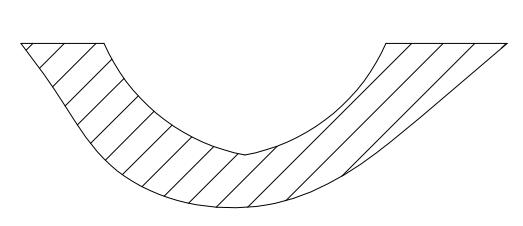

[0017] Depend on figure 1 As can be seen from the flow chart of the ball screw pair nut raceway processing process of the present invention, it includes the following steps: using the cutting edge 3 to machine the nut made of free-cutting steel to turn out the nut raceway, and obtain the intermediate piece after the turning process is completed Nuts, intermediate nuts are heat-treated and changed to obtain finished nuts, so that the tooth shape of the raceway of the finished nuts meets the requirements of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com