Fiber fabric with high buckling resistance and method for preparing fiber composite material part with high buckling resistance

A technology of fiber composite materials and fiber fabrics, which is applied in the field of fiber composite materials, can solve the problems that the buckling resistance has not been optimized to the maximum, the fiber bearing capacity has not been fully utilized, and buckling damage has achieved strong designability and is beneficial to Mass production, the effect of improving buckling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

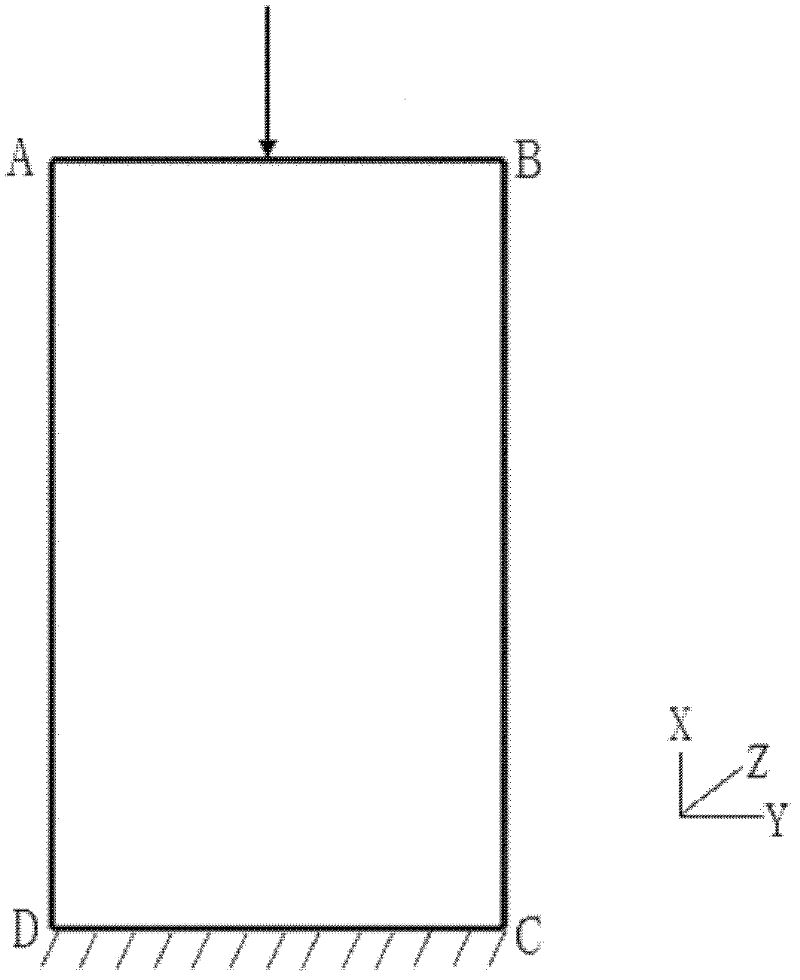

Embodiment 1

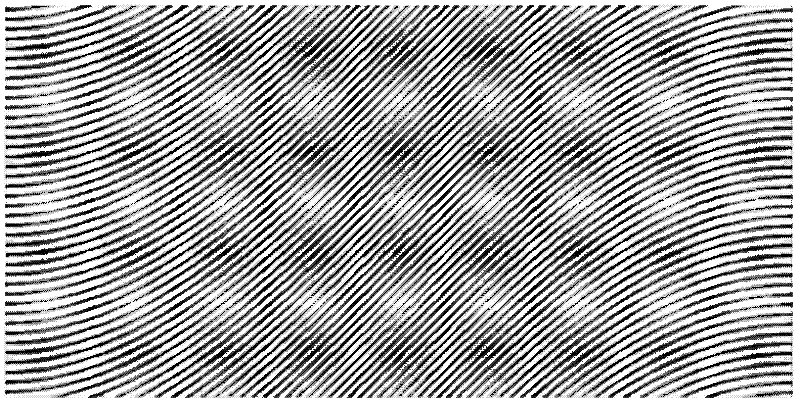

[0044]In this implementation, the shape, size and raw materials of the carbon fiber / epoxy resin composite laminate are exactly the same as those of Comparative Example 1. The difference is that in the carbon fiber / epoxy resin composite laminate, the carbon fiber fabric formed by the carbon fiber prepreg tape under the action of the adhesive has a certain shape of the fiber track, which is composed of a series of fiber tracks along a certain direction (y Axes) translation of the sinusoidal curve, its function equation expression is:

[0045] the y n =asinbx+K n (1)

[0046] Where a and b are both positive real numbers, n is a positive integer, and K n is a positive real number and K n ≠ K n+1 .

[0047] The preparation method of the above-mentioned carbon fiber / epoxy resin composite laminate is as follows:

[0048] Step 1: According to the shape and size of the rectangular carbon fiber / epoxy resin composite laminate with a size of 400mm×200mm, design a rec...

Embodiment 2

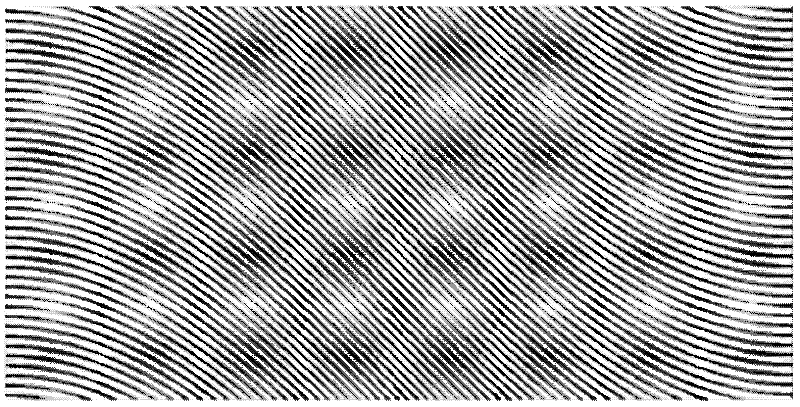

[0083] In this implementation, the shape and size of the carbon fiber / epoxy resin composite laminate is exactly the same as that of Comparative Example 2. The difference is that in the carbon fiber / epoxy resin composite laminate, the carbon fiber fabric formed by the carbon fiber prepreg tape under the action of the adhesive has a certain shape of the fiber track, which is composed of a series of fibers along a certain direction (y axis) translation obtained cosine curve, its function equation expression is:

[0084] the y n =acosbx+K n (1)

[0085] Where a and b are both positive real numbers, n is a positive integer, and K n is a positive real number and K n ≠ K n+1 .

[0086] The preparation method of the above-mentioned carbon fiber / epoxy resin composite laminate is as follows:

[0087] Step 1: prepare pre-impregnated epoxy resin, the pre-impregnated epoxy resin formula is: (1) resin: epoxy resin E-20 and epoxy resin E-54 mass ratio is 1: 1; (2) curing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com