Multifunctional module combined ocean platform and use method

An ocean platform, multi-functional technology, applied in the direction of floating buildings, etc., can solve the problems of inability to achieve batch production, assembly line, inability to reach the work site by itself, and inability to further improve performance, so as to improve material storage capacity and expand deck operations Area, the effect of realizing assembly line production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings.

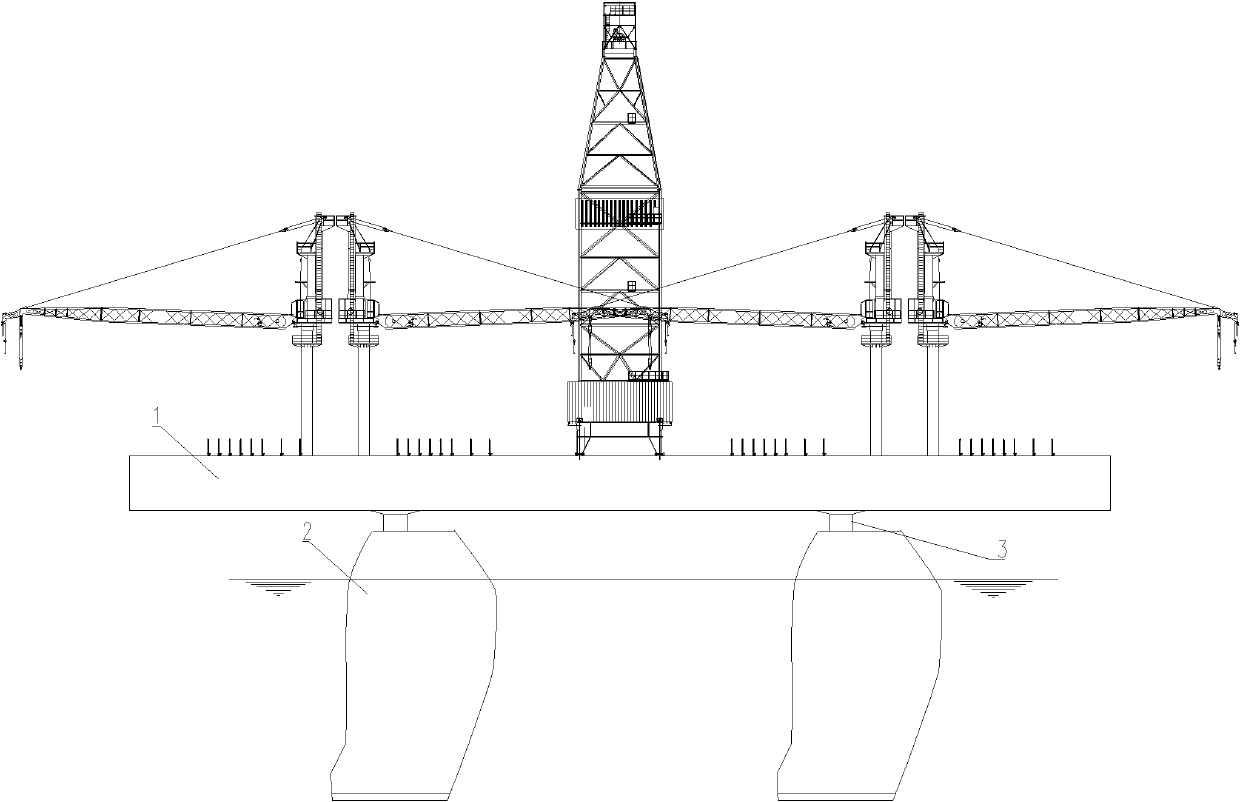

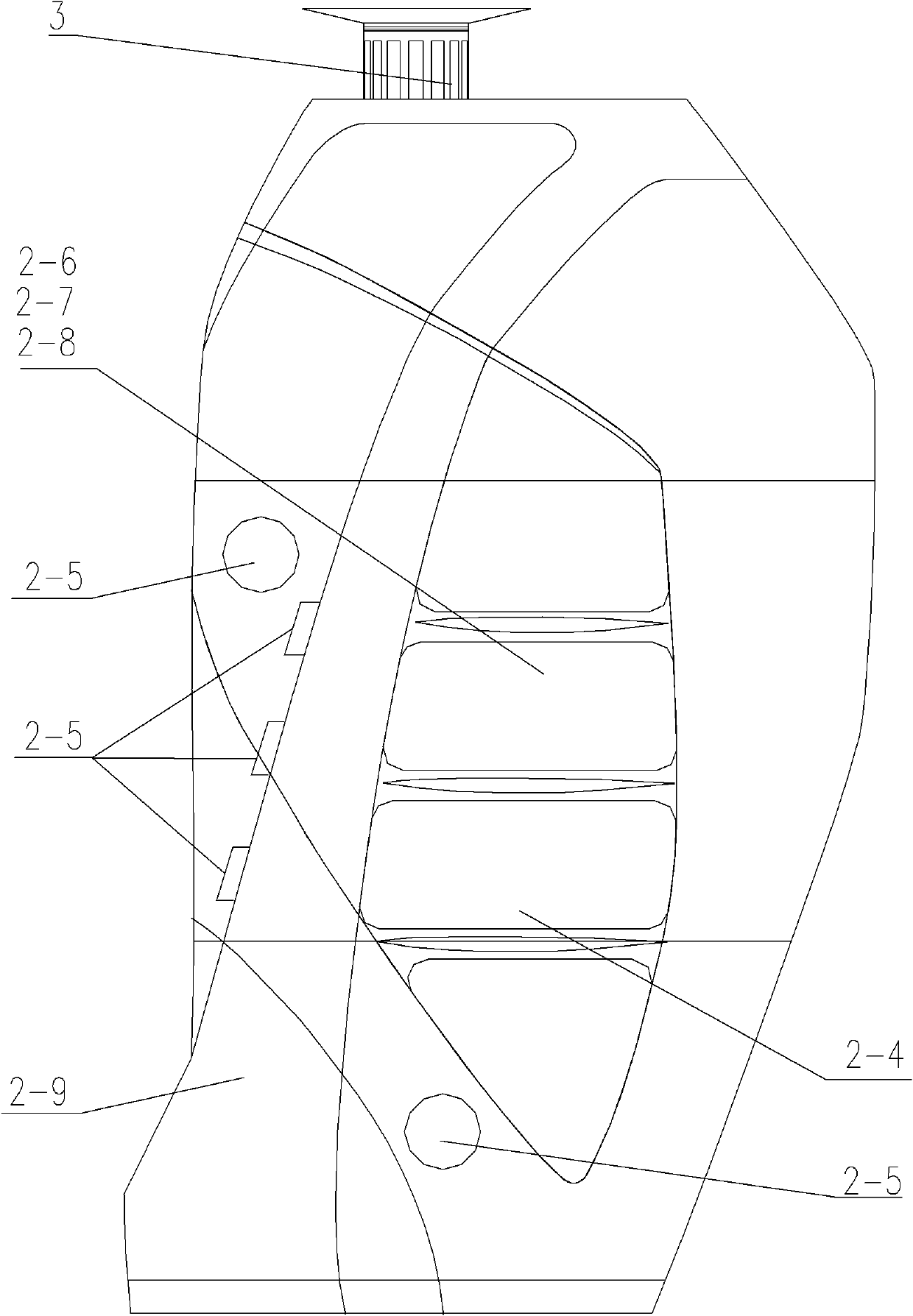

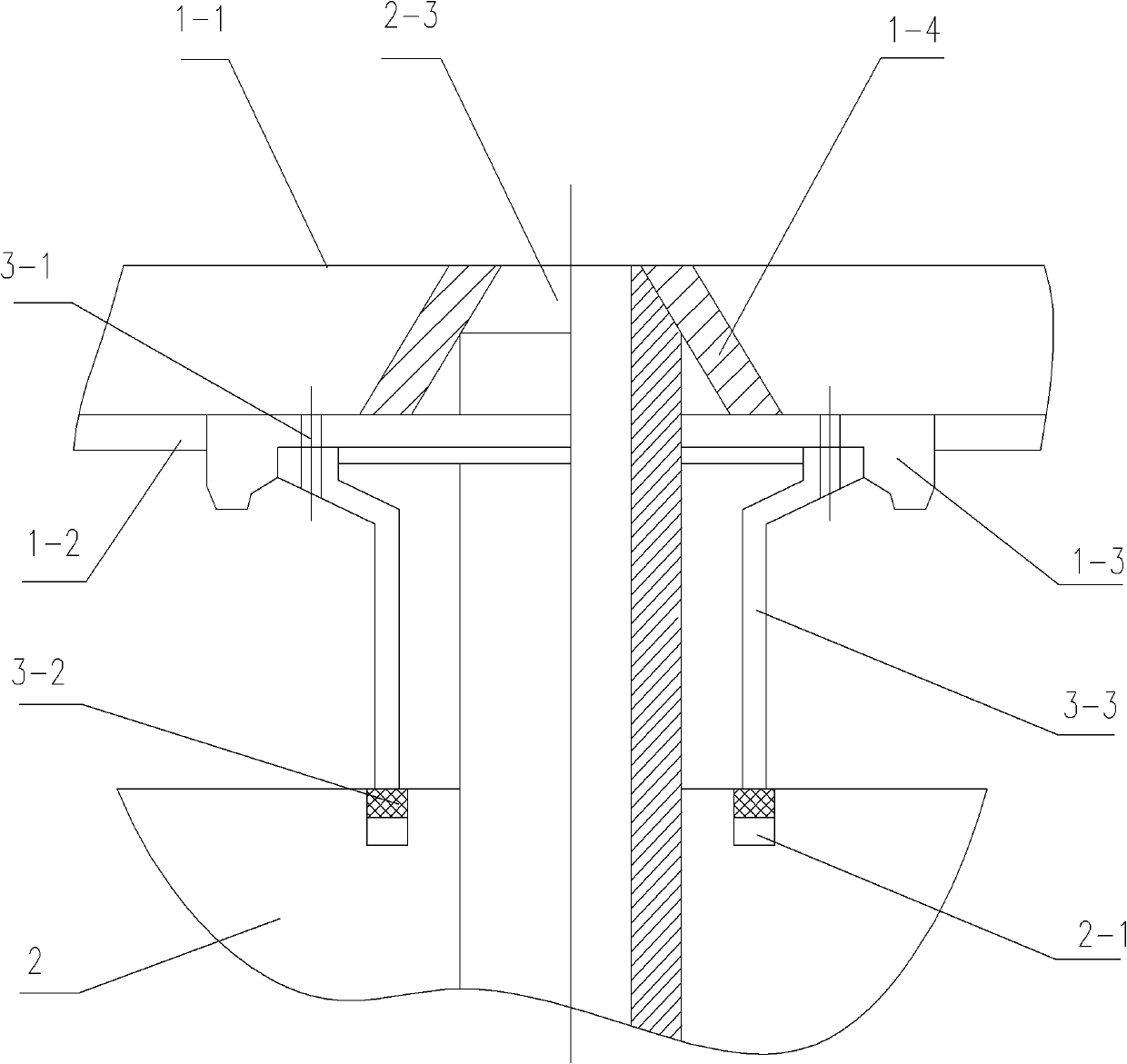

[0050] A multifunctional modular combined offshore platform, including a functional deck module 1 floating on the water surface, an auxiliary single module 2 supported by the lower part, and a connecting module 3 connecting the two; the functional deck module 1 is a non-powered flat plate structure , the operating equipment is arranged on the flat plate; the auxiliary monomer module 2 is a cylindrical structure with a circular or polygonal horizontal section, the module has a built-in power generation device, and an electric pump provides a driving water jet propulsion device, and the auxiliary monomer module 2 It is divided into a power auxiliary single module for providing power, a material auxiliary single module for placing materials, and a residential auxiliary single module with living facilities. The multifunctional modular combined offshore platform can choose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com