Method for removing impurity trichlorosilane from silicon tetrachloride

A technology of trichlorosilane and silicon tetrachloride, applied in the direction of silicon halide compounds, halosilanes, etc., to achieve a complete and easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

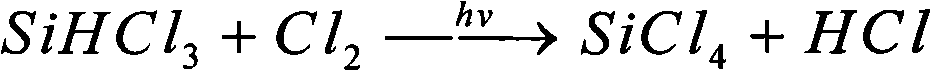

Problems solved by technology

Method used

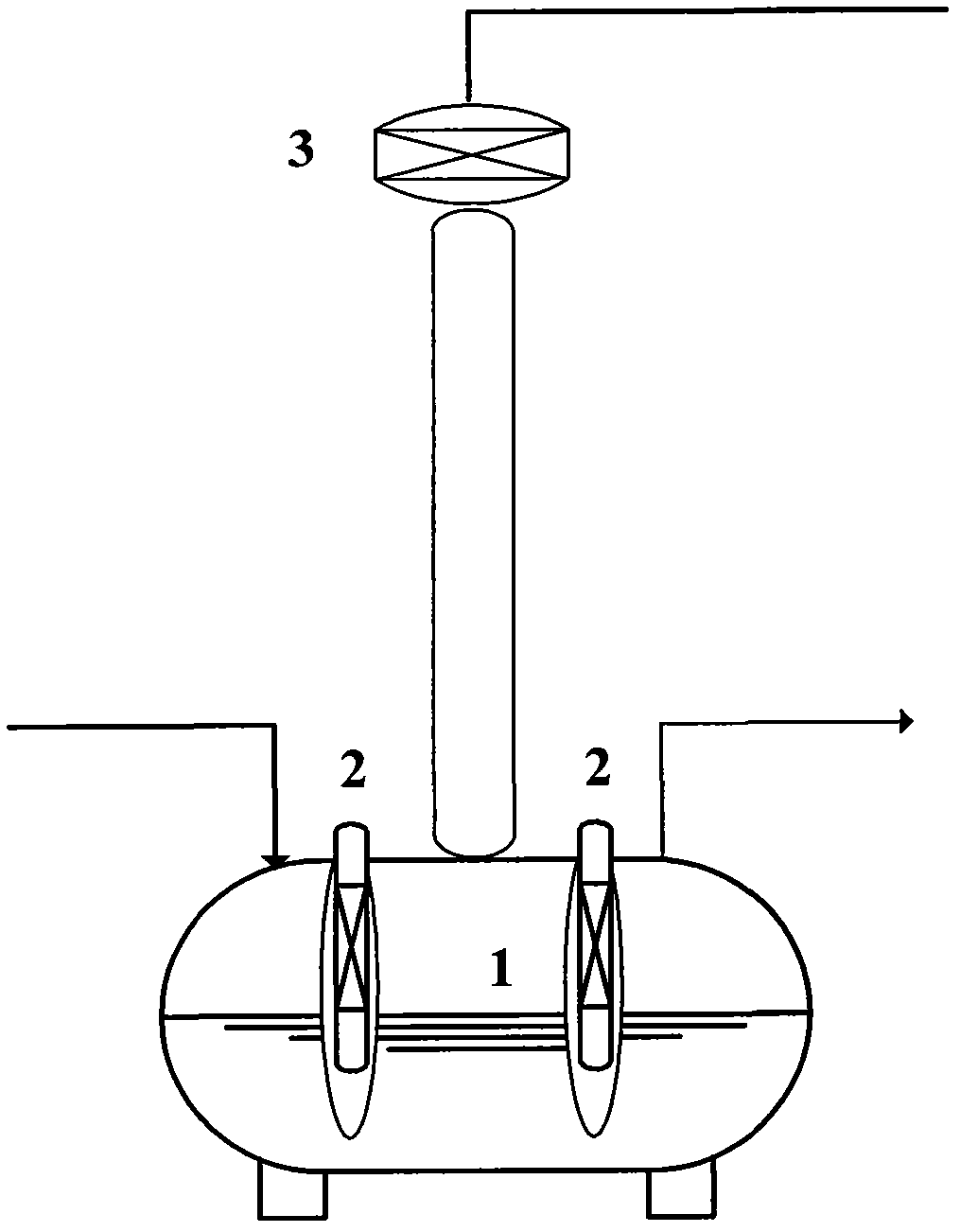

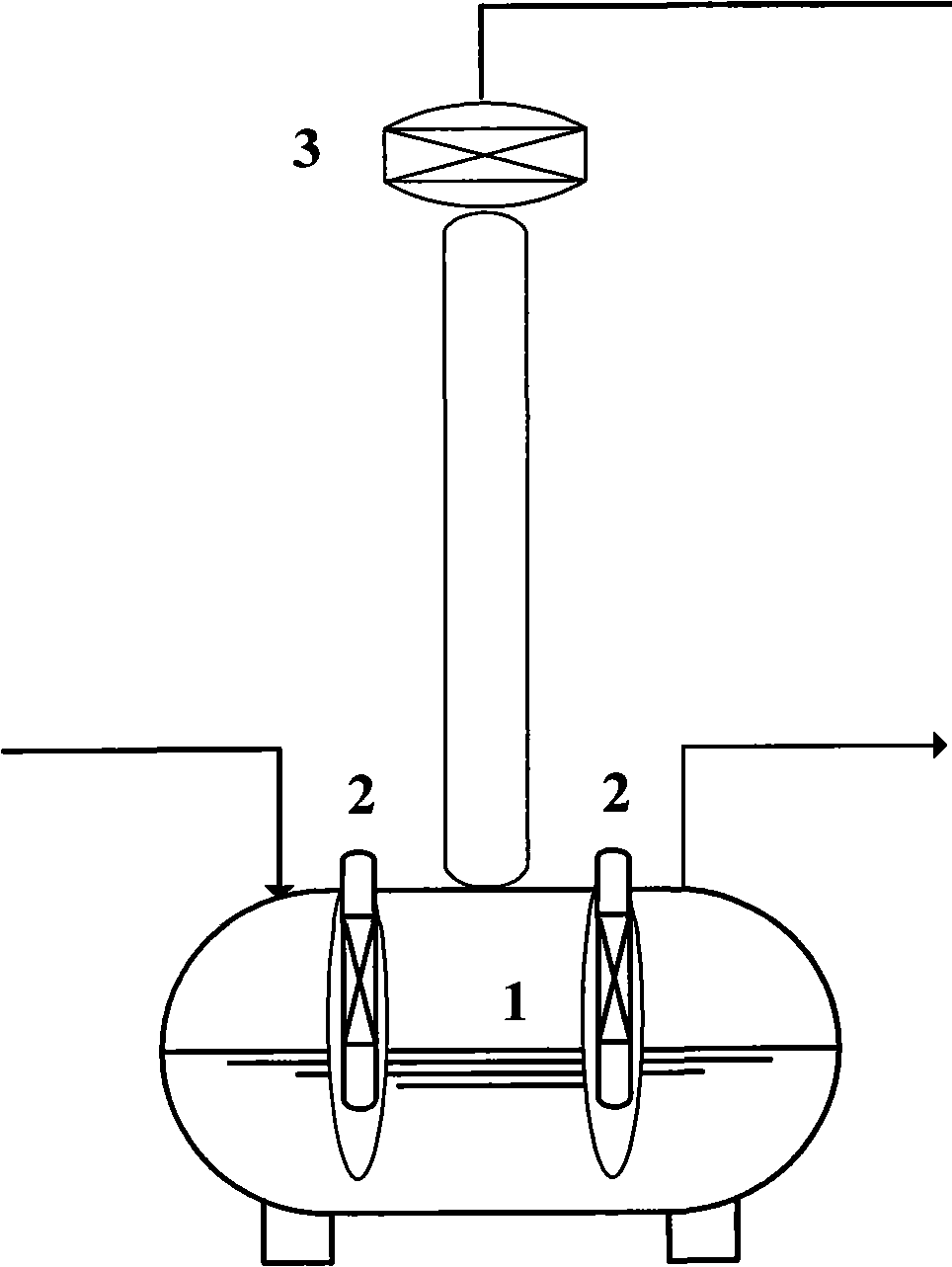

Image

Examples

Embodiment 1

[0026] Press 3.5 L of crude silicon tetrachloride raw material into the reaction vessel, and feed nitrogen into the system as a protective atmosphere. Pass excessive chlorine gas into the raw material, and illuminate under the mercury lamp for 2 hours and 30 minutes. Turn off the light source, stop the light.

Embodiment 2

[0028] Press 5 L of crude silicon tetrachloride raw material into the reaction vessel, and feed argon into the system as a protective atmosphere. Pass excessive chlorine gas into the raw material, and irradiate under mercury lamp for 3 hours and 25 minutes. Turn off the light source, stop the light.

[0029] Silicon tetrachloride purified according to the above process conditions has no absorption at the fundamental frequency of trichlorosilane in its infrared spectrum, which fully meets the requirements of silicon tetrachloride for optical fiber on the content of trichlorosilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com