PET (Polyethylene terephthalate) base material used for filter membrane, preparation method as well as filter membrane and display screen comprising PET base material

A filter film and base material technology, applied in the field of optical film materials, can solve the problems of discoloration, reduce the resistance of filter film, etc., and achieve the effect of improving color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

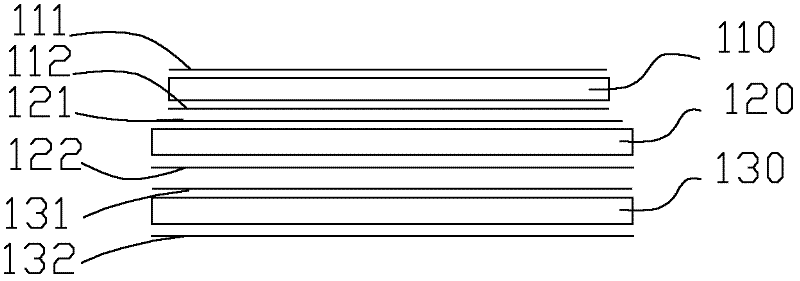

[0026] According to another aspect of the present invention, there is provided a method for preparing any one of the above PET substrates, comprising the following steps: 1) heating the transparent PET material to obtain molten PET; 2) mixing inorganic pigments, organic pigments and dyes One or more of them are added to the melted PET obtained in step 1); 3) Add dispersant and stabilizer to the product of step 2), and mix uniformly to obtain a colored PET substrate. The transparent PET substrate used in the preparation method is a commercially available PET substrate, and its preparation method is well known to those skilled in the art. Heat the commercially available transparent PET material, and when it becomes molten, add one or more of inorganic pigments, organic pigments and dyes, and also need to add some dispersants, such as white oil, DOP, turpentine , phosphates, glyceryl palmitate, glyceryl stearate and dibutyl ester, in addition, it is necessary to add a stabilizer,...

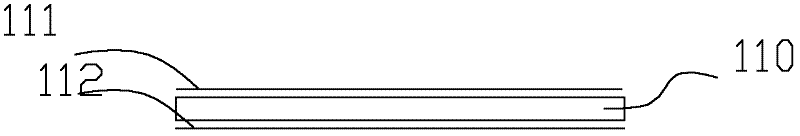

Embodiment 1

[0034] 99% of the transparent PET material (this PET material is a commercially available transparent material) is heated to a molten state, 0.1% of carbon black is added thereto, and after stirring evenly, 0.7% of glyceryl palmitate is added as a dispersant, 0.2% CaSt is used as a stabilizer, the above-mentioned substances are fully mixed, and the colored PET film is pulled out. An AR layer is deposited on the obtained colored PET film, and a pressure-sensitive adhesive PSA layer is deposited on the lower surface to obtain a final product filter film.

Embodiment 2

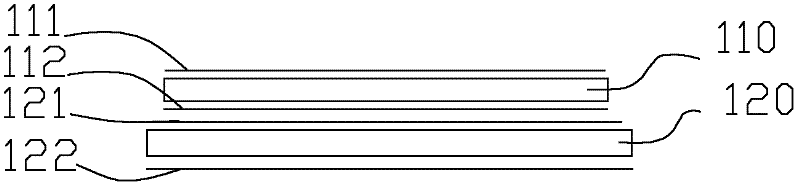

[0036] 87% of the transparent PET material (this PET material is a commercially available transparent material) is heated to a molten state, and 8% of quinophthalone and 2% of oxanaphthalene are added thereto, and 2.0% of turpentine is added after stirring As a dispersant, 1.0% MgSt is used as a stabilizer, the above substances are mixed well, and the colored PET film is pulled out. A layer of EMI function layer is deposited on the obtained colored PET film, and a pressure-sensitive adhesive PSA layer is deposited on the lower surface to obtain the final product filter film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com