Low-alkali reactive dye and its dyeing method

A technology for reactive dyes and dyeing methods, applied in the field of low-alkali reactive dyes and their dyeing, can solve the problems of not meeting ecological requirements and environmental protection requirements, consuming a lot of human and material resources, consuming soda ash and dyes, etc., and achieving excellent compatibility. and dyeing stability, ensuring dyeing reproducibility, and reducing dyeing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

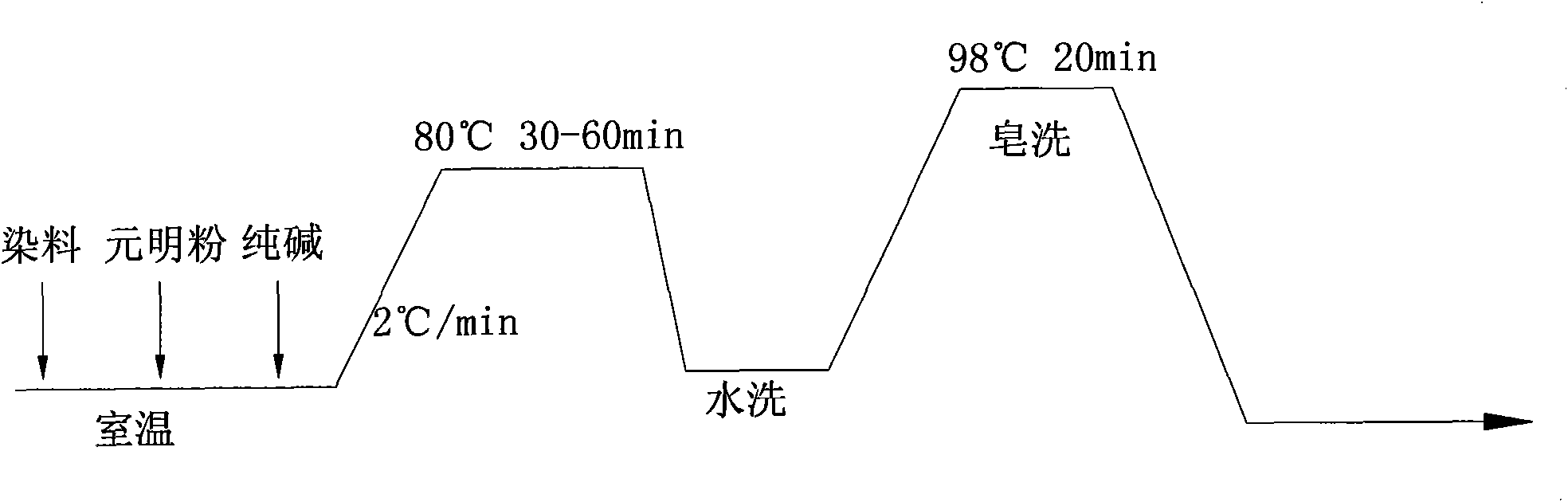

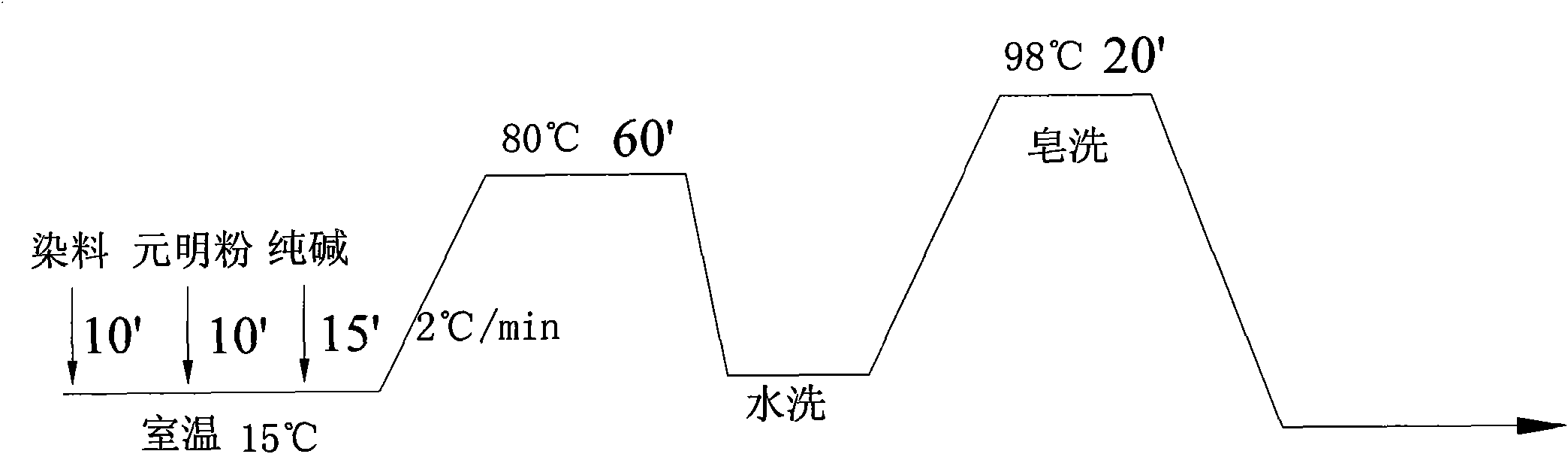

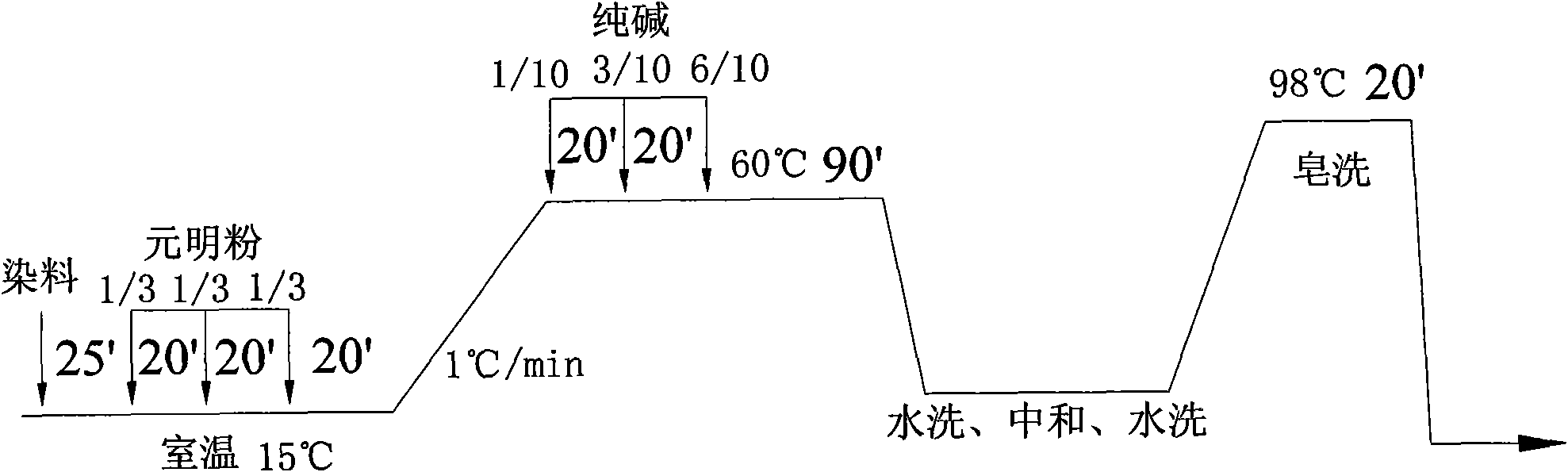

[0031] Such as figure 1 As shown, the present embodiment discloses the general technical process of the present invention, and the method comprises:

[0032] (1) the step of adding low-alkali reactive dyes, sodium sulfate, and soda ash to the dye vat successively under normal temperature conditions; the concentration of soda ash added in the adding step is 1 to 5 grams per liter;

[0033] Among them, 10-100 grams per liter of sodium sulfate, X% of low-alkali reactive dyes, the amount of X% of reactive dyes is directly proportional to the amount of sodium sulfate, and its proportional relationship is common sense in this industry, so it will not be done here Too much narrative.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com