Paint, preparation method thereof and coating moulding method

A coating and coating technology, used in coatings, polyester coatings, and devices for coating liquids on the surface, etc., can solve the problems of peeling and delamination, and the sealing coating is easy to foam, and achieves coating adhesion. The effect of stability, good impact and friction resistance, and excellent coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

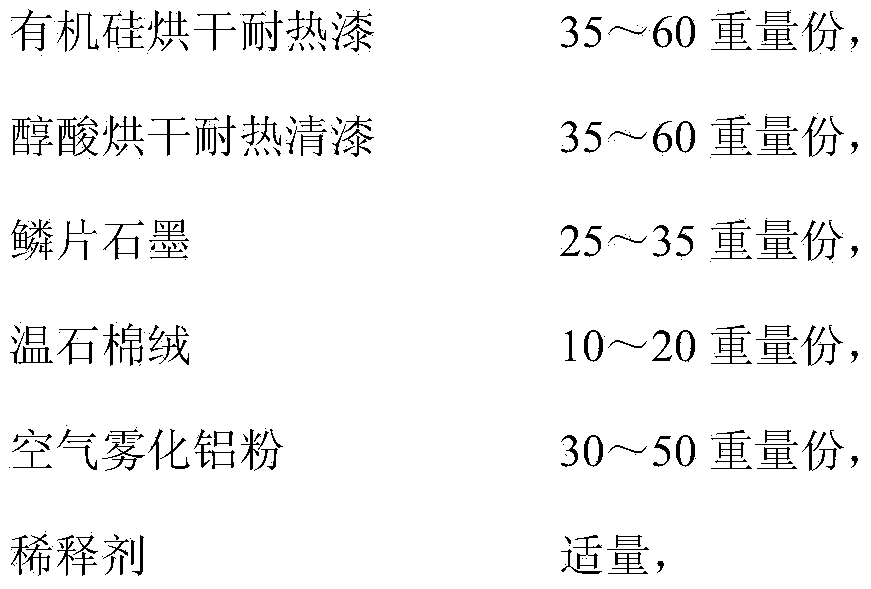

[0024] The coating of the present invention includes: 50 parts by weight of organic silicon baking heat-resistant paint, 50 parts by weight of alkyd baking heat-resistant varnish, 28 parts by weight of flake graphite, 16 parts by weight of chrysotile wool, and 40 parts by weight of air atomized aluminum powder And an appropriate amount of diluent, the diluent is preferably amino paint diluent.

[0025] The coating preparation method: weigh 50 parts by weight of organic silicon drying heat-resistant paint, 50 parts by weight of alkyd drying heat-resistant varnish, 28 parts by weight of flake graphite, 16 parts by weight of chrysotile wool and 40 parts by weight of air atomized aluminum powder Put the parts into the container and mix evenly; then add an appropriate amount of amino paint thinner, first stir with a wooden stick, and then mechanically stir until it is evenly paste. Preferably, before mixing and stirring, the flake graphite is placed in a 250°C temperature environment ...

Embodiment 2

[0027] The coating of the present invention includes: 35 parts by weight of organic silicon baking heat-resistant paint, 35 parts by weight of alkyd baking heat-resistant varnish, 25 parts by weight of flake graphite, 10 parts by weight of chrysotile wool, and 30 parts by weight of air atomized aluminum powder And an appropriate amount of diluent, the diluent is preferably amino paint diluent.

[0028] The preparation method of the coating: weigh 35 parts by weight of organic silicon drying heat-resistant paint, 35 parts by weight of alkyd drying heat-resistant varnish, 25 parts by weight of flake graphite, 10 parts by weight of chrysotile wool and 30 parts by weight of air atomized aluminum powder Put the parts into the container and mix evenly; then add an appropriate amount of amino paint thinner, first stir with a wooden stick, and then mechanically stir until it is evenly paste. Preferably, preferably, prior to mixing and stirring, the flake graphite is placed in a 200°C tem...

Embodiment 3

[0030] The coating of the present invention includes: 60 parts by weight of organic silicon baking heat-resistant paint, 60 parts by weight of alkyd baking heat-resistant varnish, 35 parts by weight of flake graphite, 20 parts by weight of chrysotile wool, and 50 parts by weight of air atomized aluminum powder With an appropriate amount of diluent, the diluent is preferably xylene.

[0031] The coating preparation method: weigh 60 parts by weight of organic silicon drying heat-resistant paint, 60 parts by weight of alkyd drying heat-resistant varnish, 35 parts by weight of flake graphite, 20 parts by weight of chrysotile wool and 50 parts by weight of air atomized aluminum powder Put the parts into the container and mix evenly, add an appropriate amount of xylene, and stir well until it becomes a paste. Preferably, before mixing and stirring, the flake graphite is placed in a 300℃ temperature environment for baking for 1.5 hours, and then sieved with a 250 mesh screen; before mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com