Hydrolysis treatment method of straw hemicellulose

A technology of straw cellulose and hemicellulose, applied in the production of sugar, sugar production, food science, etc., can solve the problem of low efficiency of hydrolysis equipment, reduce the burden of purification process, save manpower and material resources, save The effect of removing manpower and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

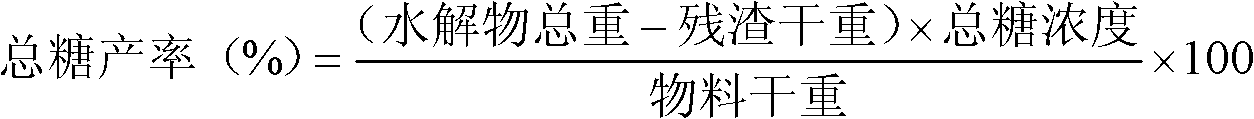

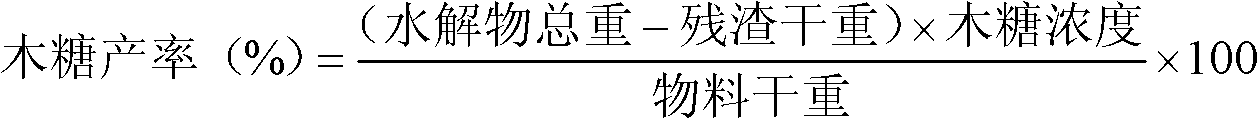

[0031] According to solid: liquid = 1: 10, add 1.8% sulfuric acid to the pulverized material, hydrolyze for 90min at 121°C, measure the total sugar and xylose of the hydrolyzate by HPLC, calculate the productive rate of total sugar and xylose according to the following formula, and use this Serve as a reference standard for comparison between different hydrolysis conditions.

[0032]

[0033]

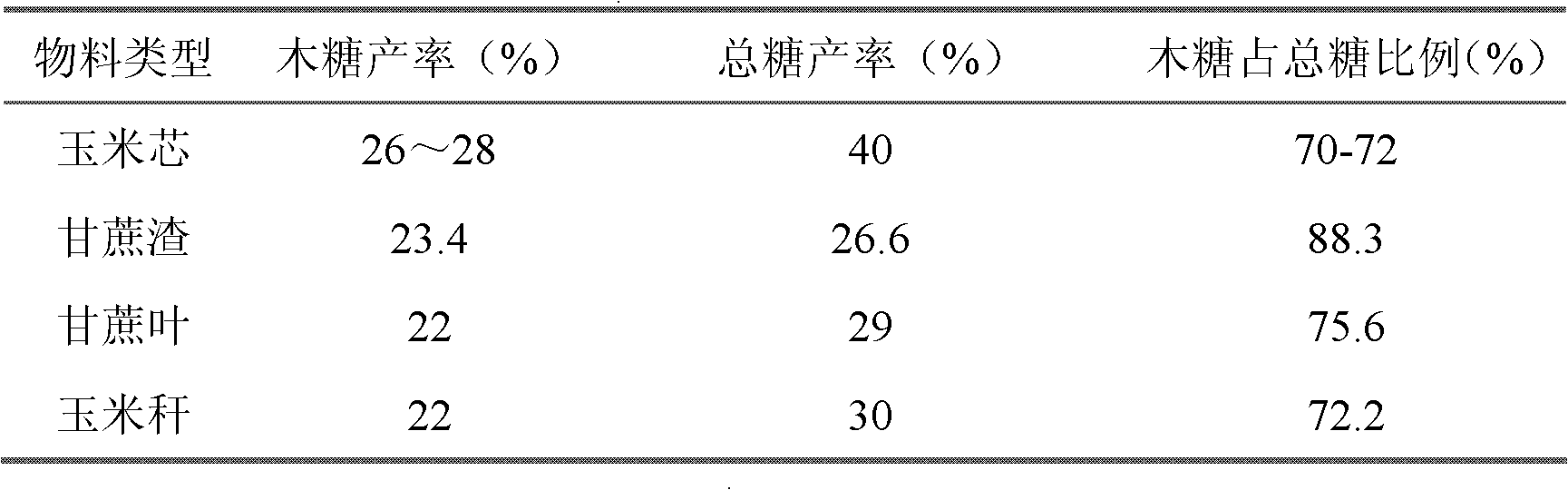

[0034] Table 1 Total sugar and xylose yields of dilute acid hydrolyzates of different straw raw materials

[0035]

Embodiment 2

[0036] The method of embodiment 2 quick pickling of stalks

[0037] The main obstacle affecting the pickling speed is the air in the material. If the air inside the corncob tissue is removed, or the pressure of the pickling solution is extracted, and the acid is directly pressed into the inside of the corncob, the pickling efficiency should be accelerated. In this example, taking corn cobs with complete morphology as the object, the effects of four different pickling methods on pickling were compared and studied in a 50L hydrolysis tank. Method 1, pickling in vacuum, that is, evacuating the hydrolysis tank full of materials to -0.9Mpa, then injecting acid solution (1.5% sulfuric acid) to soak the materials, and maintaining normal pressure for pickling for a certain period of time. Method two, vacuum-pressure pickling. After vacuumizing the material, inject acid solution, and directly use a pump to pressurize to 0.04Mpa for pickling for a certain period of time. Method three,...

Embodiment 3

[0043] Example 3 Corn cob hydrolysis in a conventional pot

[0044] After obtaining a 50L hydrolysis tank with corncobs in a regular density pot, an applicable pickling method and basic hydrolysis conditions, a 1t hydrolysis tank was used for verification in this example.

[0045] 1t hydrolysis tank (stainless steel) single-tank corn cob (water content about 14%) 116-120kg, the pressure swing pickling process is basically the same as the conditions of the 50L tank. The specific process is: after charging, use a pump to inject acid solution (1.3% sulfuric acid) until the acid solution flows out of the overflow port, close the overflow valve and continue to pump the acid solution to 0.2MPa, and open the overflow valve to drain to 0.2MPa after maintaining pressure for 15 minutes. 0MPa, pump the acid solution to 0.2MPa for the second time and maintain the pressure for 45 minutes, open the overflow valve to drain to 0MPa, and pump the acid solution to 0.2MPa for the third time and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com