Heat treatment method of martensite stainless steel forge piece for nuclear power reactor internals pressure spring

A technology of martensitic stainless steel and heat treatment method, which is applied in the field of heat treatment of martensitic stainless steel forgings used for compression springs of nuclear power reactor internal components, can solve problems such as difficult production and unsatisfactory performance, and achieve the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

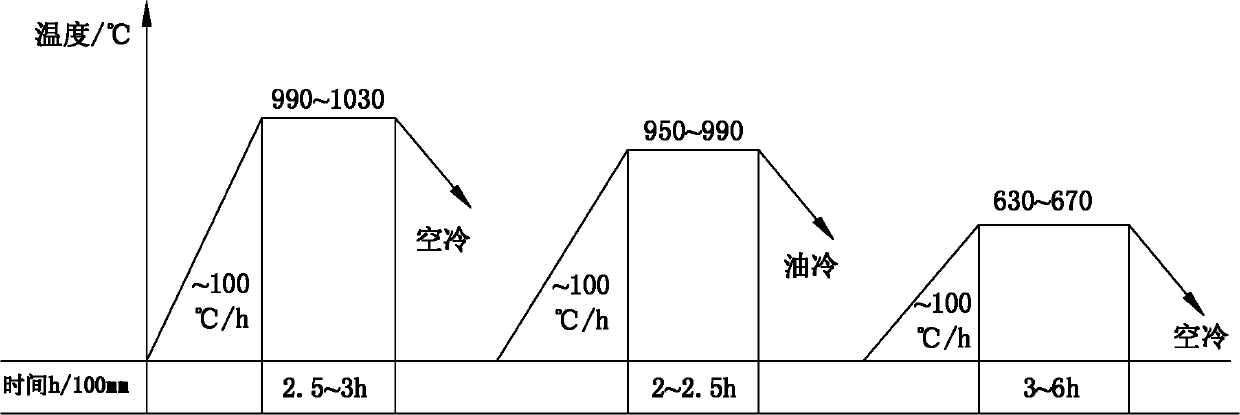

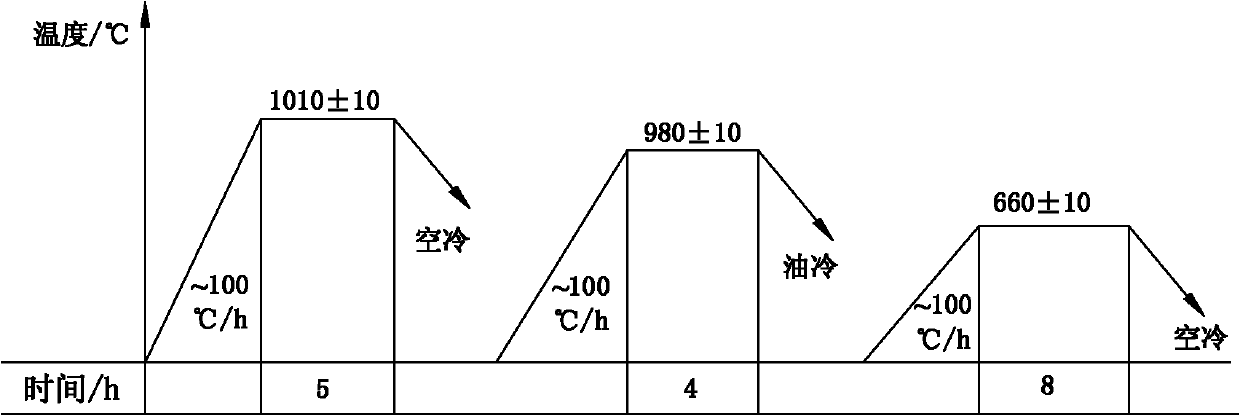

[0020] Such as figure 1 As shown, the heat treatment method of the martensitic stainless steel forging used for the compression spring of the internal component of the nuclear power reactor of the present invention comprises the following steps:

[0021] The first step, preparatory heat treatment (air quenching);

[0022] Let the workpiece enter the heating furnace, and rapidly heat it to a high temperature of 990-1030°C at a speed of 100±10°C / hour, austenitize and fully dissolve chromium carbide; heat preservation, heat preservation time is 2.5-2.5 to 100mm per heat treatment equivalent thickness 3 hours to confirm; after that, the workpiece is lifted out of the heating furnace and air-cooled to obtain a structure of lath-shaped martensite + a small amount of ferrite;

[0023] The second step, quenching (oil quenching);

[0024] Make the workpiece enter the heating furnace and heat it up to 950-990°C at a speed of 100±10°C / hour; heat preservation, the heat preservation time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com