Method for preparing aluminium magnesium silicon alloy rod base and preparing high-strength aluminium magnesium silicon alloy conductor

A technology of aluminum alloy rods and aluminum-silicon intermediate alloys, which is applied in the field of electrical engineering, can solve problems such as artificial aging treatment and unsatisfactory material properties, and achieve the effects of stable performance and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Aluminum ingots, aluminum-silicon master alloys, aluminum-rare earth alloy aluminum ingots, aluminum-boron master alloys, and aluminum-magnesium master alloys are selected as raw materials.

[0040] The aluminum ingot is an electrician aluminum ingot with the brand name Al99.7E, and the specific composition (percentage, wt%) of the aluminum ingot is as follows: Fe<0.20, Si<0.07, Cu<0.01, Mg<0.02, Zn<0.04, B<0.01 0.04, Cr<0.004, (Mn+Ti+Cr+V)<0.02, the content of each other impurity element shall not be greater than 0.03wt%, and the total content of impurity elements shall not be greater than 0.30wt%.

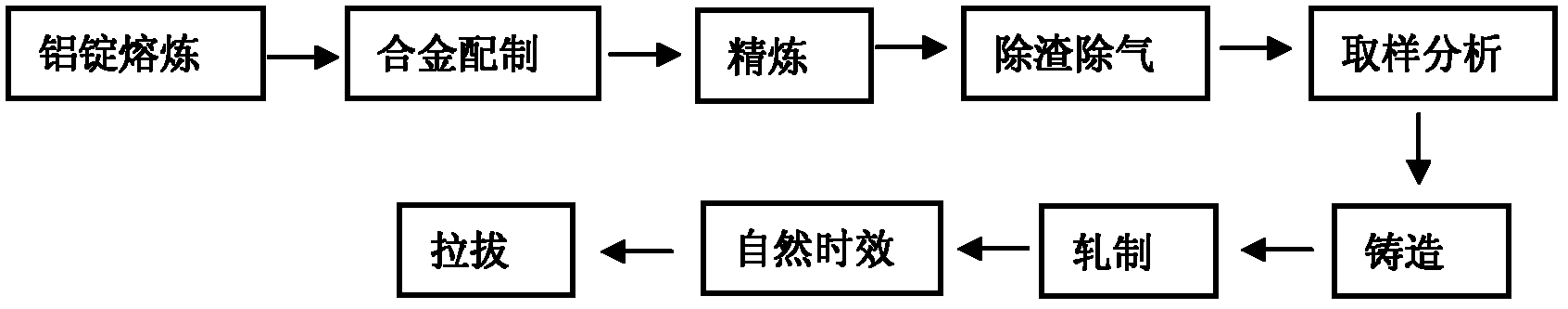

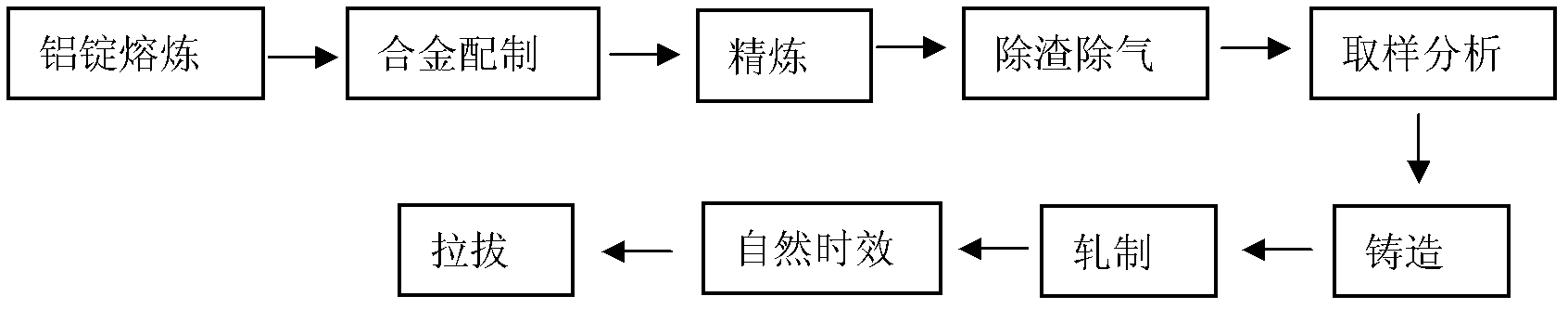

[0041] The silicon content in the aluminum-silicon master alloy is 11wt%; the aluminum-rare earth alloy contains 10wt% of mixed rare earths, and the cerium content in the mixed rare earths is not less than 45wt%; the boron content in the aluminum-boron master alloy is 1wt%; the aluminum-magnesium master alloy The content of magnesium in the medium is 50wt%. Such as figur...

Embodiment 2

[0044] Aluminum ingots, aluminum-silicon master alloys, aluminum-rare earth alloy aluminum ingots, aluminum-boron master alloys, and aluminum-magnesium master alloys are selected as raw materials.

[0045] The aluminum ingot is an electrician aluminum ingot with the brand name Al99.7E, and the specific composition (percentage, wt%) of the aluminum ingot is as follows: Fe<0.20, Si<0.07, Cu<0.01, Mg<0.02, Zn<0.04, B<0.01 0.04, Cr<0.004, (Mn+Ti+Cr+V)<0.02, the content of each other impurity element shall not be greater than 0.03wt%, and the total content of impurity elements shall not be greater than 0.30wt%.

[0046] The silicon content in the aluminum-silicon master alloy is 12wt%; the aluminum-rare earth alloy contains 8wt% of mixed rare earths, and the cerium content in the mixed rare earths is not less than 45wt%; the boron content in the aluminum-boron master alloy is 1wt%; the aluminum-magnesium master alloy The content of magnesium in the medium is 55wt%. Such as figure...

Embodiment 3

[0049] Aluminum ingots, aluminum-silicon master alloys, aluminum-rare earth alloy aluminum ingots, aluminum-boron master alloys, and aluminum-magnesium master alloys are selected as raw materials.

[0050] The aluminum ingot is an electrician aluminum ingot with the brand name Al99.7E, and the specific composition (percentage, wt%) of the aluminum ingot is as follows: Fe<0.20, Si<0.07, Cu<0.01, Mg<0.02, Zn<0.04, B<0.01 0.04, Cr<0.004, (Mn+Ti+Cr+V)<0.02, the content of each other impurity element shall not be greater than 0.03wt%, and the total content of impurity elements shall not be greater than 0.30wt%.

[0051] The silicon content in the aluminum-silicon master alloy is 9wt%; the aluminum-rare earth alloy contains 11wt% of mixed rare earths, and the cerium content in the mixed rare earths is not less than 45wt%; the boron content in the aluminum-boron master alloy is 1.5wt%; The content of magnesium in the alloy is 45wt%. Such as figure 1 As shown, the aluminum ingots ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com