Construction method of extruded polystyrene foamed plastic insulation boards in house energy-saving materials

A technology of extruded polystyrene and energy-saving materials, applied in the processing of building materials, thermal insulation, building components, etc. The construction quality is safe and reliable, the crack resistance is excellent, and the operation steps are reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A construction method for residential energy-saving material extruded polystyrene foam insulation board, characterized in that it includes the following steps:

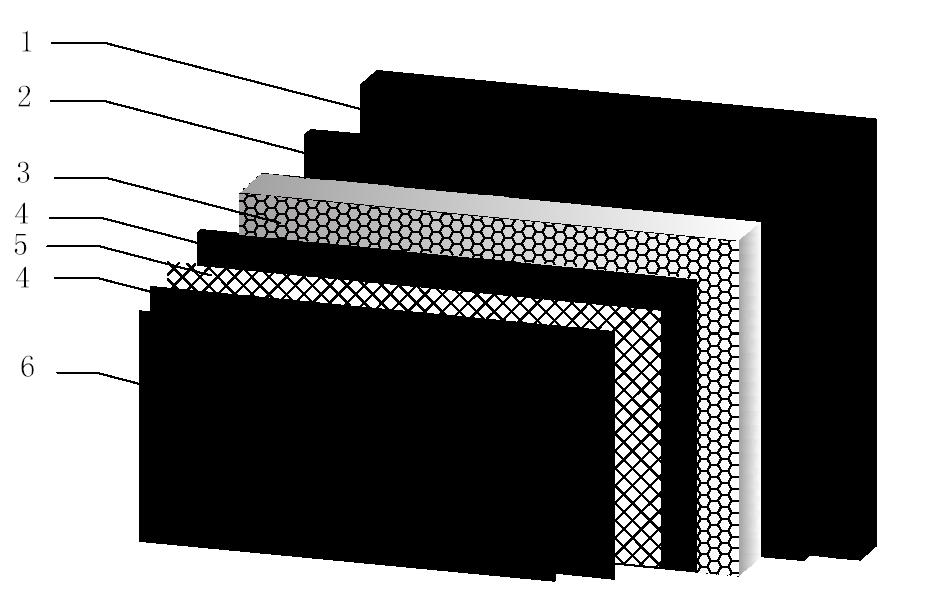

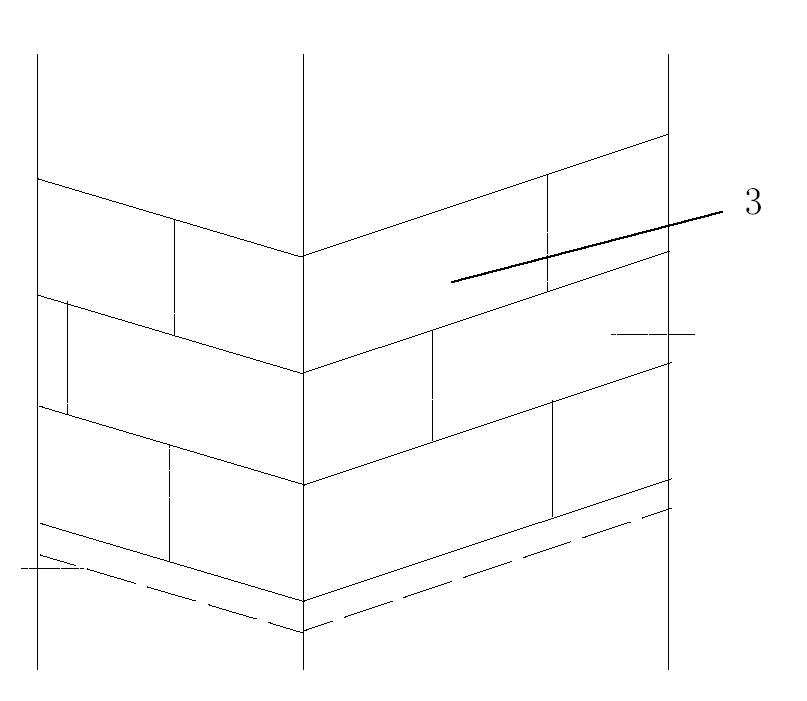

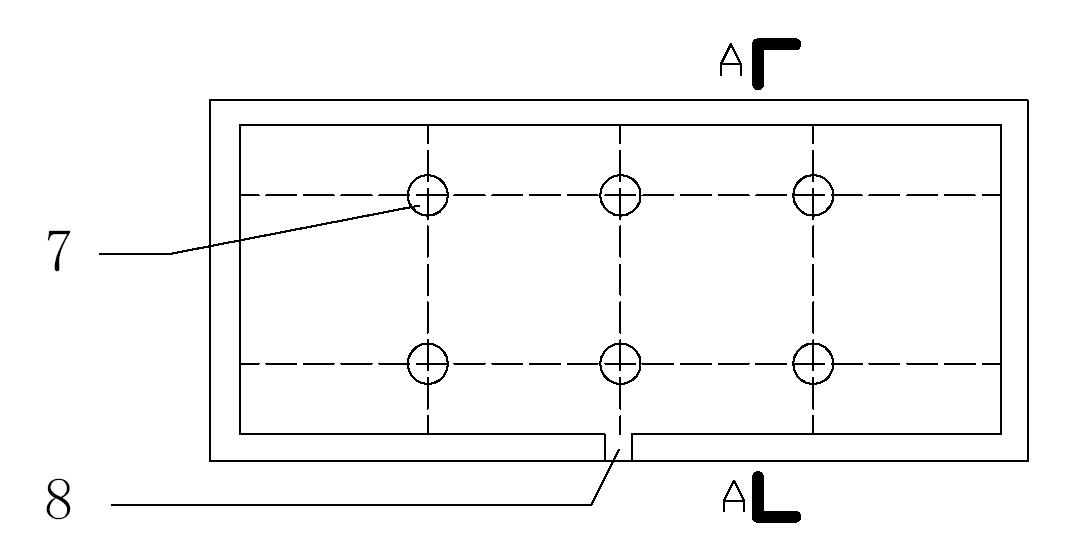

[0064] figure 1 It is a schematic diagram of the external wall insulation structure of the embodiment of the present invention.

[0065] a. Concrete wall base 1 cleaning, including:

[0066] 1) Clean up the residual floating ash on the concrete wall, the release agent oil and sundries;

[0067] 2) Remove the concrete of the structural column protruding from the wall, the mortar blocks on the masonry wall, and the remaining floating ash;

[0068] 3) Remove the split concrete blocks, inclusions, and hollows at the joints of the shear wall, and repair and fill various external wall openings;

[0069] 4) The deviation of the flatness of the wall surface pasted with XPS board 3 does not exceed 4mm. If it exceeds, polish the protruding wall, and make repairs to the recessed parts (if the thickness exceeds 6mm, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com