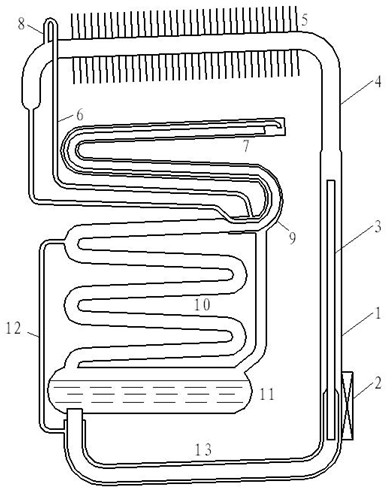

Evaporator with absorption type core filled with carbon fibers or materials with high water absorbability

An evaporator and water absorption technology, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of manufacturing cost or processing difficulty, and cannot further improve the refrigeration performance of the core, and achieve a large heat transfer temperature difference. , Effective use, the effect of improving evaporation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] In this embodiment, the outer tube of the evaporator adopts a steel pipe with an outer diameter of 25 mm and an inner diameter of 22 mm (wall thickness 1.5 mm);

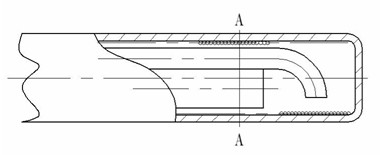

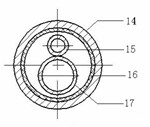

[0024] Production of carbon fiber filler: First, the inner mold of the carbon fiber layer mold is made by car, the size is as follows Figure 4 Shown: the carbon fiber flat fiber strip (non-woven fabric), twisted into a cylindrical fiber strip, the diameter is about 1mm thick. In the process of twisting carbon fiber strips, the frame is driven to wind the fiber strips on the inner mold, and the outer diameter is controlled to match the inner diameter of the above-mentioned steel pipe. After reaching a sufficient length, it is cut off and the end is fixed. Since carbon fiber is composed of multiple fibers, the outer diameter of winding can be determined by the tightness of twisting when forming a strip and the tightness of winding to the mold rod. After the size basically meets the requirements, the surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com