Detection device for surface-shape errors of solar trench type curved surface reflector

A surface error and detection device technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of cumbersome and time-consuming detection process, complex image processing, not suitable for fast, online detection, etc. Simple, low-cost image processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

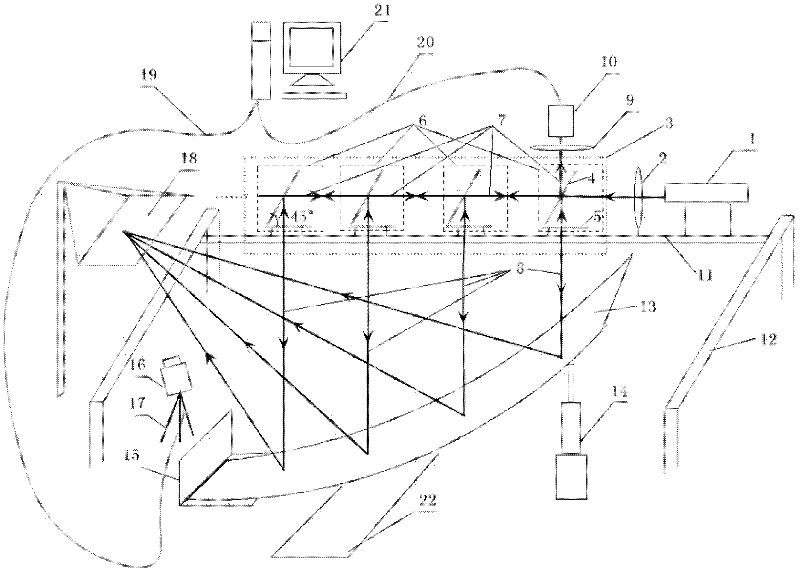

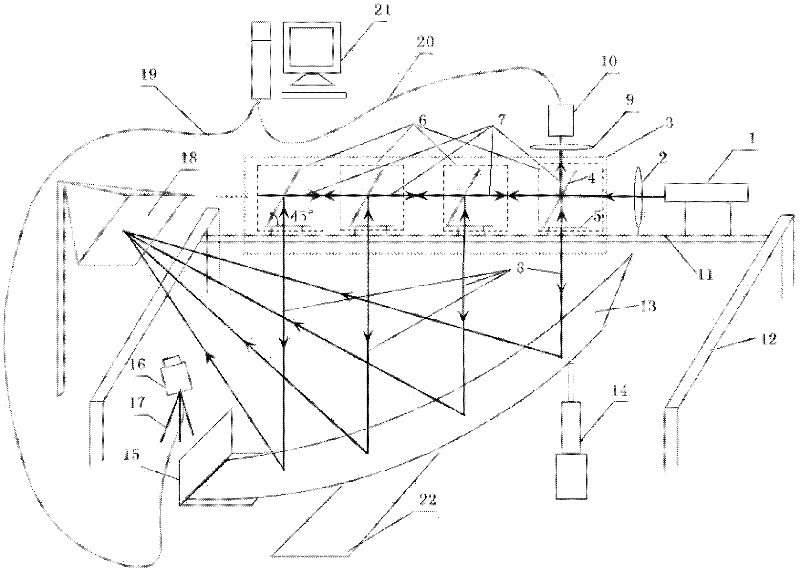

[0011] Specific implementation mode 1. Combination figure 1 In this embodiment, the device for detecting the surface error of the solar trough curved reflector includes a light source device, a self-calibration device, and an image acquisition and processing device.

[0012] Described light source device comprises laser 1, beam expander mirror 2 and beam splitting mirror group 3; Described beam splitting mirror group 3 is made up of a series of beam splitting mirror units 6, and each beam splitting mirror unit 6 is made up of two pieces Beam mirror composition (tilt beam splitter 4 and horizontal beam splitter 5), the angle between the two beam splitters is 45°.

[0013] The beam expander 2 expands and collimates the laser beam emitted by the laser 1, divides it into a series of test beams 8 with approximately equal energy and parallel to each other through the beam splitter group 3, and projects them onto the curved mirror 13 under test. The position and inclination of each ...

specific Embodiment approach 2

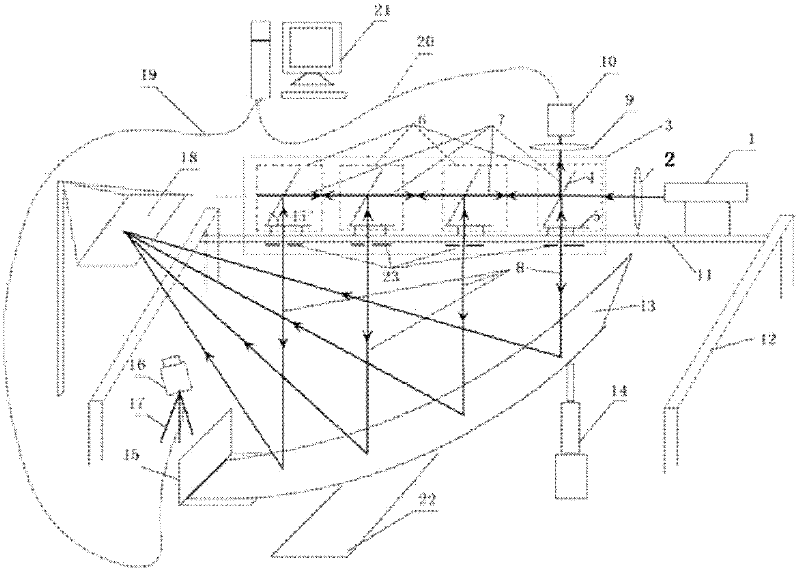

[0018] Specific embodiment two, combine figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that this embodiment adds a shutter 23 to each beam splitter unit 6 on the basis of the first embodiment. 13 surface error is tested, it is necessary to add a shutter 23 in each beam splitter unit. When the surface error detection is performed on the measured curved surface mirror 13, when the light spot projected on the light screen deviates from the ideal position, it can be Close all the shutters 23, and open the shutters 23 in turn from left to right, then the measured point corresponding to the deviated spot can be found, and the normal direction of the measured point can be obtained from the deviation of the light spot and the coordinate information of the measured point The deviation from the ideal normal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com