Detection method of free chlorine ions in polyisobutylene

A technology of polyisobutylene and detection method, which is applied in the chemical industry to achieve the effects of simple operation, low cost and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

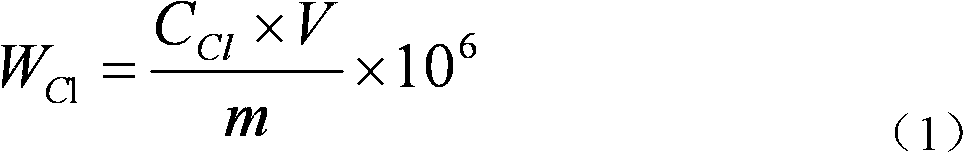

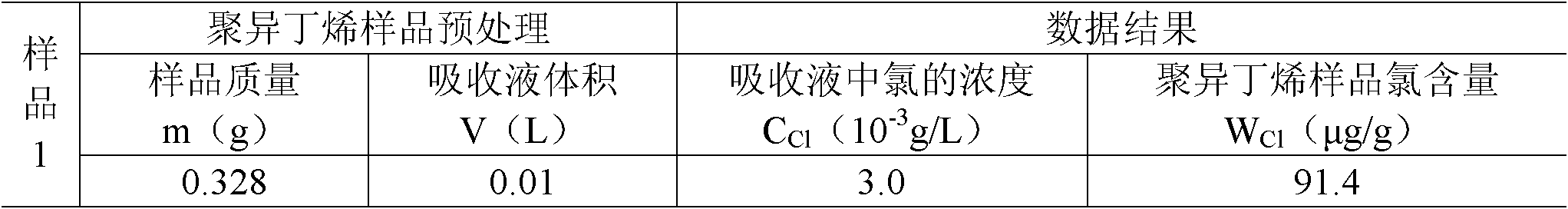

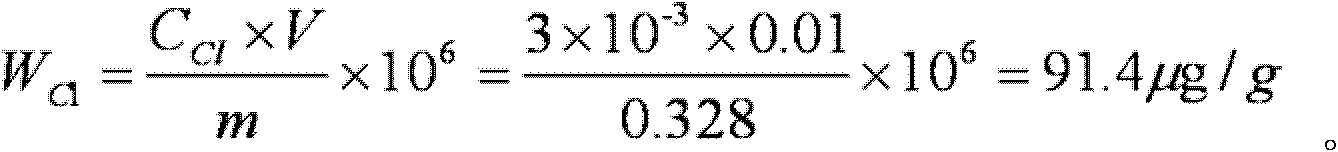

[0032] (1) Dissolution of polyisobutylene: Weigh 0.328 g of polyisobutylene (sample 1, weight average molecular weight M w = 100,000) was dissolved in 50 mL of tetrahydrofuran to make a homogeneous solution;

[0033] (2) Extraction of chloride ions in polyisobutylene: under stirring conditions, the homogeneous solution prepared in step (1) was slowly added dropwise to 100 mL of ultrapure water, and after the polyisobutylene was precipitated from the water, the solution was subjected to high-speed Centrifugal separation, time 15min, rotating speed 4500rpm; pour out the supernatant liquid; wash the precipitated polyisobutene with 10mL ultrapure water twice, combine the supernatant liquid and washing solution; evaporate the tetrahydrofuran and water in the extraction solution; add 10mL ultrapure water; Wash with pure water to extract chloride ions, shake repeatedly, so that the chloride ions on the inner wall of the container are completely dissolved in the aqueous solution to ob...

Embodiment 2

[0040] (1) Dissolution of polyisobutylene: Weigh 0.791 g of polyisobutylene (sample 2, weight average molecular weight M w = 67,000) was dissolved in 50 mL of tetrahydrofuran to make a homogeneous solution;

[0041] (2) Extraction of chloride ions in polyisobutylene: under stirring conditions, the homogeneous solution prepared in step (1) was slowly added dropwise to 100 mL of ultrapure water, and after the polyisobutylene was precipitated from the water, the solution was subjected to high-speed Centrifugal separation, time 20min, rotating speed 4600rpm; pour out the supernatant liquid; wash the precipitated polyisobutene with 10mL ultrapure water twice, combine the supernatant liquid and washing solution; evaporate the tetrahydrofuran and water in the extraction solution; add 10mL ultrapure water; Wash with pure water to extract chloride ions, shake repeatedly, so that the chloride ions on the inner wall of the container are completely dissolved in the aqueous solution to obt...

Embodiment 3

[0048] (1) Dissolution of polyisobutylene: Weigh 0.324 g of polyisobutylene (sample 3, weight average molecular weight M w = 149,000) was dissolved in 50 mL of tetrahydrofuran to make a homogeneous solution;

[0049] (2) Extraction of chloride ions in polyisobutylene: under stirring conditions, the homogeneous solution prepared in step (1) was slowly added dropwise to 100 mL of ultrapure water, and after the polyisobutylene was precipitated from the water, the solution was subjected to high-speed Centrifugal separation, time 20min, rotating speed 4600rpm; pour out the supernatant liquid; wash the precipitated polyisobutene with 10mL ultrapure water twice, combine the supernatant liquid and washing solution; evaporate the tetrahydrofuran and water in the extraction solution; add 10mL ultrapure water; Wash with pure water to extract chloride ions, shake repeatedly, so that the chloride ions on the inner wall of the container are completely dissolved in the aqueous solution to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com