Thermoelectric module and manufacture method thereof

A technology of a thermoelectric module and a manufacturing method, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, thermoelectric devices using only Peltier or Seebeck effect, etc. Sudden reduction in module service life, reliability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

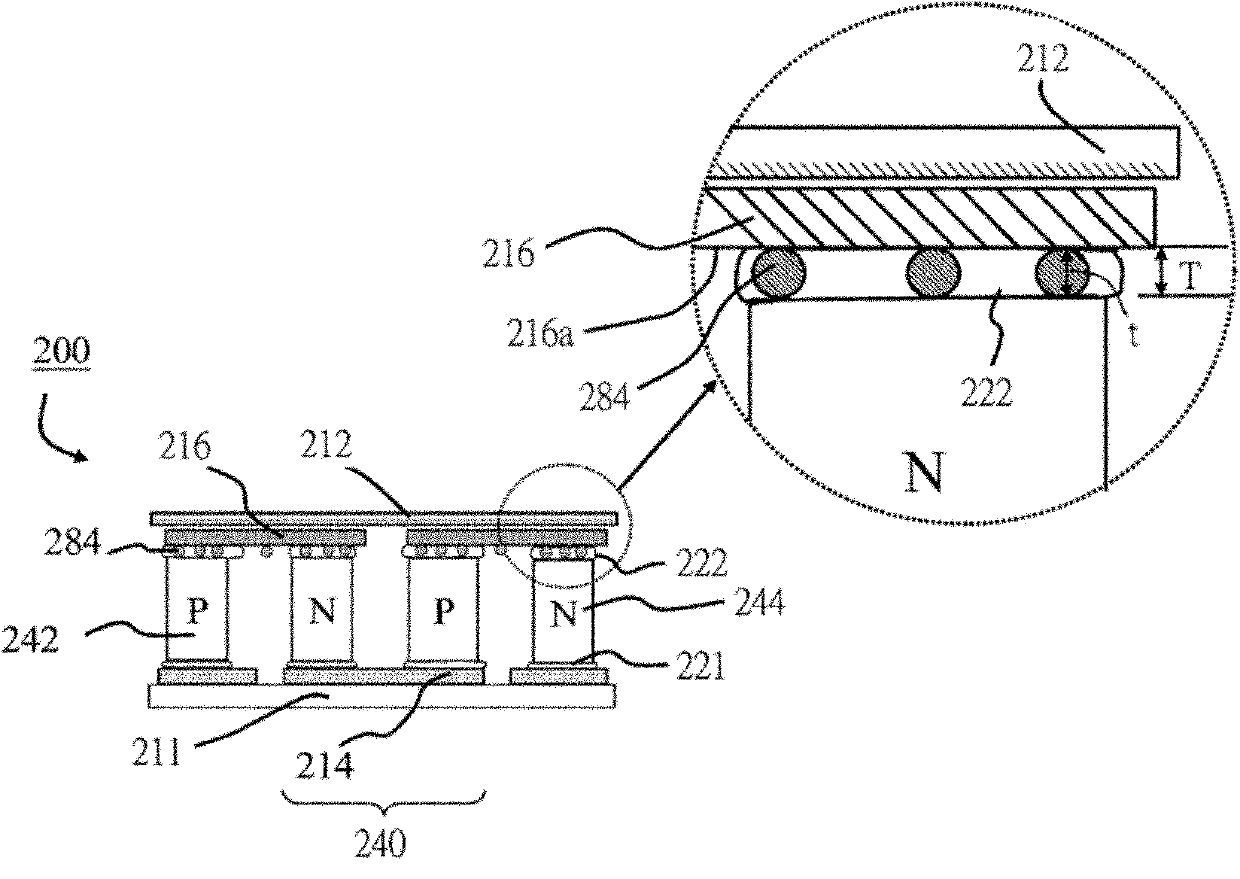

[0072] figure 2 A schematic diagram of a thermoelectric module according to a first embodiment of the present invention is shown. The thermoelectric module 200 includes a first substrate 211 and a second substrate 212 oppositely arranged, a plurality of P-type thermoelectric materials 242 and N-type thermoelectric materials 244, a plurality of first metal electrodes 214 and a second metal electrode 216, a plurality of first A solder alloy layer 221 and a second solder alloy layer 222, and supports. In this embodiment, strip supports 284 are used as supports.

[0073] Multiple pairs of thermoelectric materials 240 are disposed between the first substrate 211 and the second substrate 212, each pair of thermoelectric materials 240 includes a P-type thermoelectric material 242 and an N-type thermoelectric material 244 electrically connected, and each pair of thermoelectric materials N-type The thermoelectric material 244 is electrically connected to the P-type thermoelectric ma...

no. 2 example

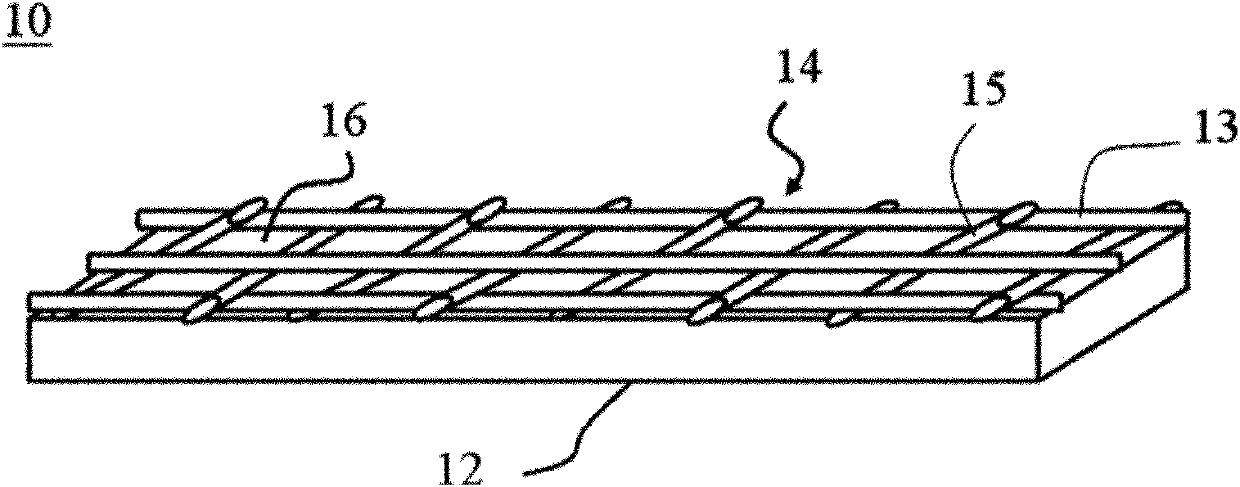

[0091] Figure 4 A schematic diagram of a thermoelectric module according to a second embodiment of the present invention is shown. Different from the thermoelectric module 200 of the first embodiment, the thermoelectric module 300 of the second embodiment uses a granular support 384 as a support. Furthermore, in the thermoelectric module 300 , the cross-arranged multi-nodal P-type thermoelectric materials 342 and multi-nodal N-type thermoelectric materials 344 are formed by bonding P1 and P2, N1 and N2 thermoelectric materials, respectively.

[0092] Figure 4 Among them, the thermoelectric module 300 includes a first substrate 311 and a second substrate 312 oppositely arranged, a plurality of nodal P-type thermoelectric materials 342 and nodal N-type thermoelectric materials 344, a plurality of first metal electrodes 314 and second metal electrodes 314 An electrode 316 , a plurality of first and second solder alloy layers 321 , 322 , and a particulate support 384 .

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com