Particulate water absorbent and method for producing same

A manufacturing method and granular technology, applied in chemical instruments and methods, absorbent pads, other chemical processes, etc., can solve problems such as difficult performance and insufficiency, and achieve odorless urine resistance, excellent coloration prevention performance over time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

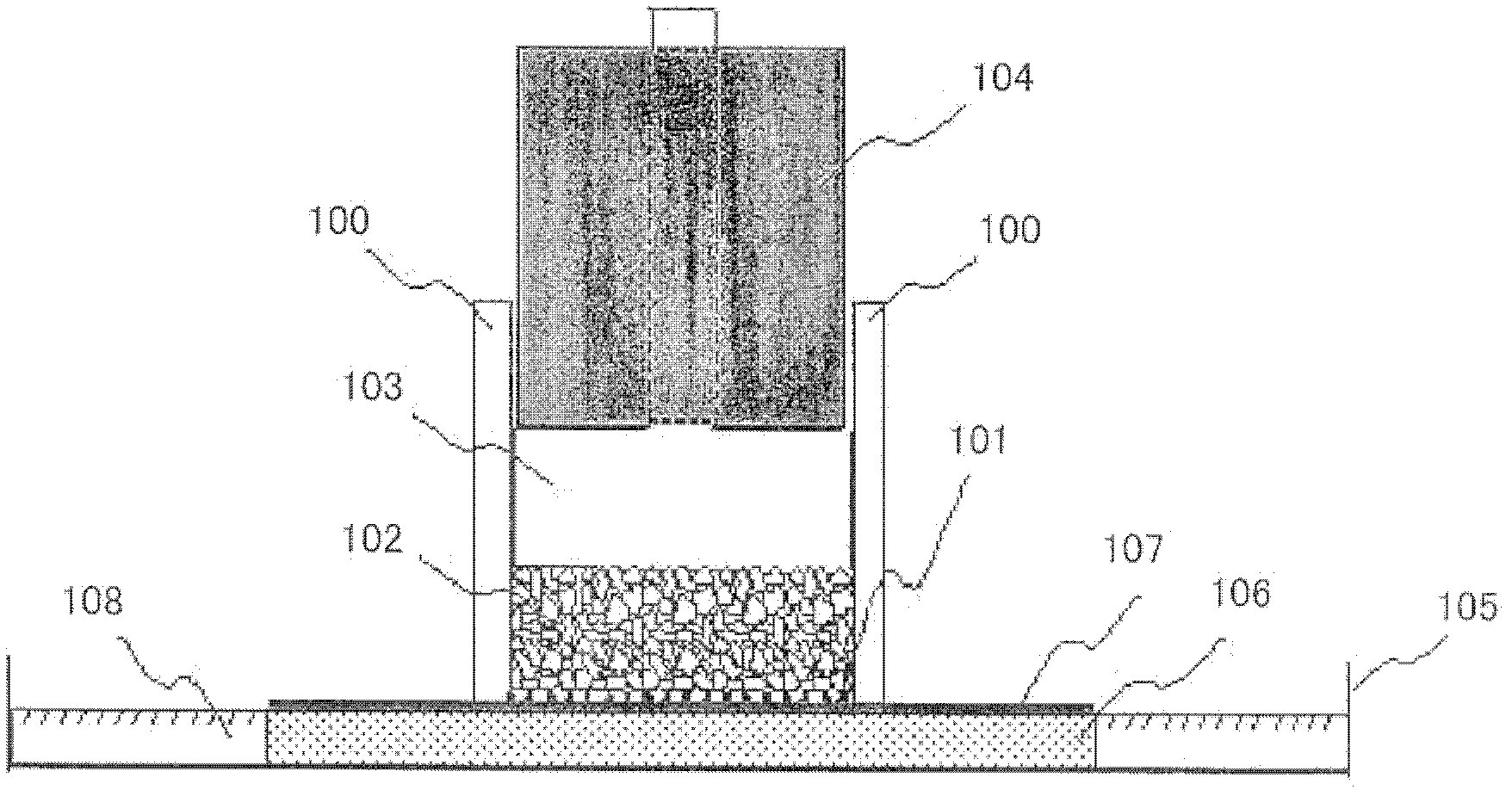

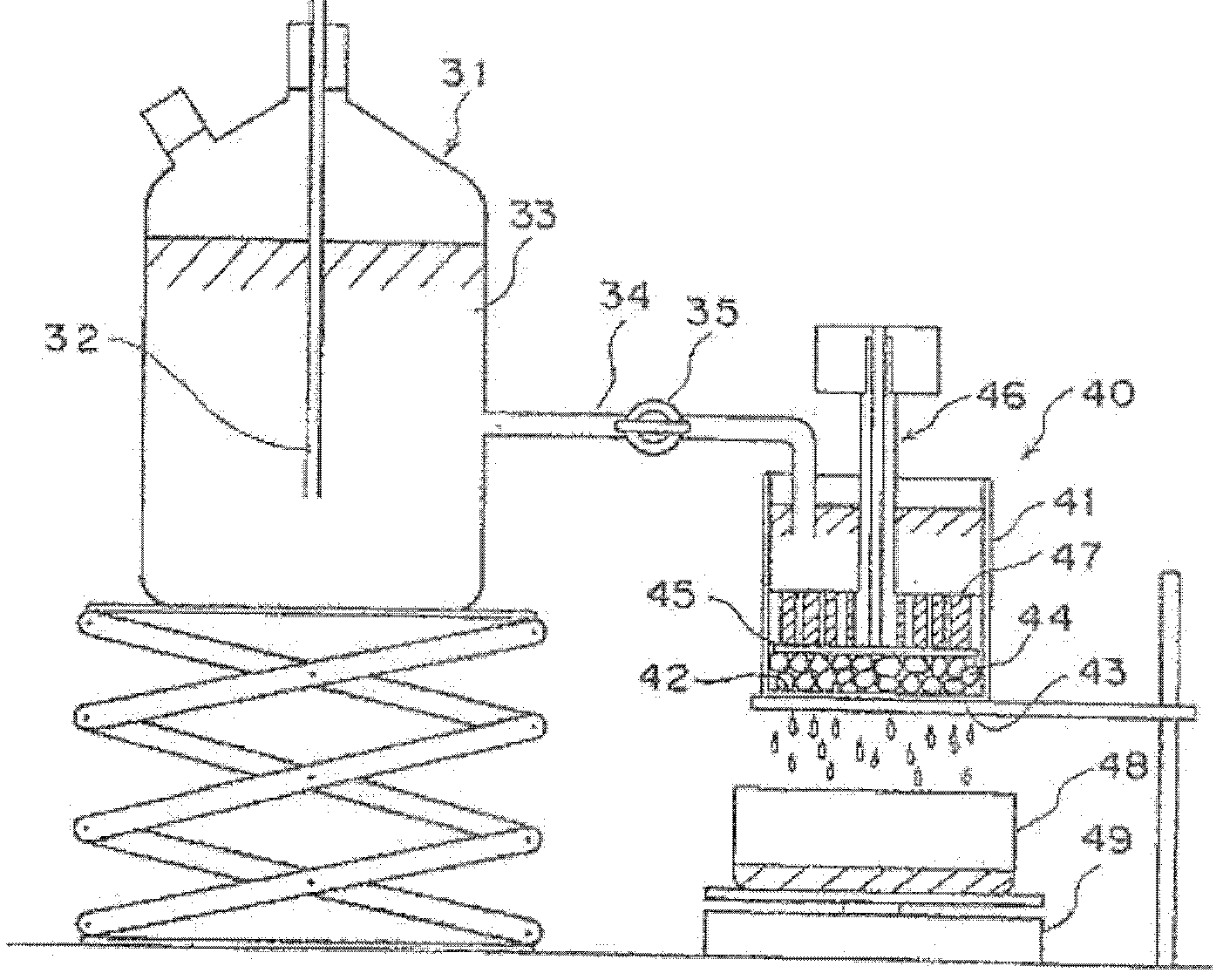

[0520] Using the method described in US Patent No. 7,265,190 image 3 In the shown device, a hydrogel-like cross-linked polymer was produced according to the following method.

[0521] First, an aqueous monomer solution (1-1) was prepared comprising: 35.2 parts by weight of acrylic acid adjusted to 70 ppm of p-methoxyphenol content, 11.7 parts by weight of a 48% by weight aqueous sodium hydroxide solution, polyethylene glycol diacrylic acid 0.23 parts by weight of an ester (average number of ethylene oxide units: n=9), 0.22 parts by weight of an aqueous solution of 1% by weight of trisodium diethylenetriaminepentaacetate (abbreviation: DTPA·3Na) as a chelating agent, and 33.6 parts by weight of deionized water parts by weight.

[0522] Next, the monomer aqueous solution (1-1) adjusted to 40° C. was continuously supplied to the polymerization step using a metering pump. 177 parts by weight of a 48% by weight sodium hydroxide aqueous solution (0.7 ppm of iron content (with res...

Embodiment 1-2

[0528] Except that the addition amount of the 30% by weight sodium bisulfite aqueous solution described in Example 1-1 was changed from 1.66 parts by weight to 3.33 parts by weight, the granular water-absorbing agent (1-1) was obtained in the same manner as Example 1-1. 2). Table 1 describes the physical properties of the obtained particulate water-absorbing agent (1-2).

Embodiment 1-3

[0530]Except that the addition amount of the 30% by weight sodium bisulfite aqueous solution described in Example 1-1 was changed from 1.66 parts by weight to 0.166 parts by weight, a water-absorbing agent was obtained in the same manner as in Example 1-1. To 100 parts by weight, 0.6 parts by weight of a 50% by weight sodium lactate aqueous solution was further added and mixed to obtain a particulate water-absorbing agent precursor (1-3). Next, the obtained particulate water-absorbing agent precursor (1-3) was placed in a hot air dryer at 60°C for 30 minutes, and then passed through a JIS standard sieve with a mesh size of 710 μm to obtain a granular water-absorbing agent precursor (1-3). agent (1-3). The water content of the obtained particulate water-absorbing agent (1-3) was 2.0% by weight. The physical properties of the obtained particulate water-absorbing agent (1-3) are described in Table 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com