Manufacturing method of machine parts excellent in rolling fatigue life

一种滚动疲劳寿命、机械部件的技术,应用在发动机元件、抗离心力的转动部件、机械设备等方向,能够解决破损、短寿命、不能够充分实现机械部件和装置等问题,达到提高滚动疲劳寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] As an example of the present invention, conditions and obtained results will be described. First, Table 1 shows the component composition of the test material used as the steel type of the ring-shaped base material 2 .

[0037] Table 1

[0038] Components of the test material (unit is mass %)

[0039]

[0040] In this example, the test materials of the steel types shown in Table 1 were implemented. First, the molten steel is oxidized and refined in an arc melting furnace, then reduced and refined in a ladle refining furnace (LF), and degassed by a circular vacuum degasser (RH) to reduce the oxygen content in the molten steel , the molten steel is manufactured into steel ingots by continuous casting. This steel ingot is hot-rolled as usual to form a steel material, and after that, a steel pipe is formed by a three-roll mill, and a conventional heat treatment for spheroidizing is prepared.

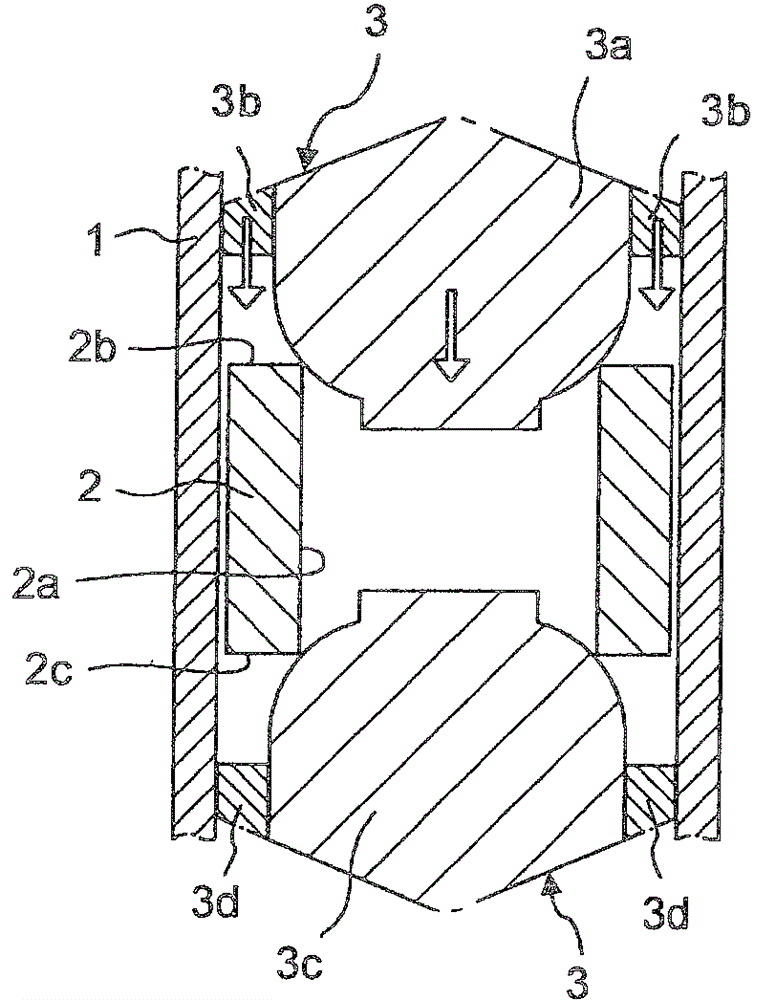

[0041] Cut the steel pipe composed of the test material shown in Ta...

Embodiment 2

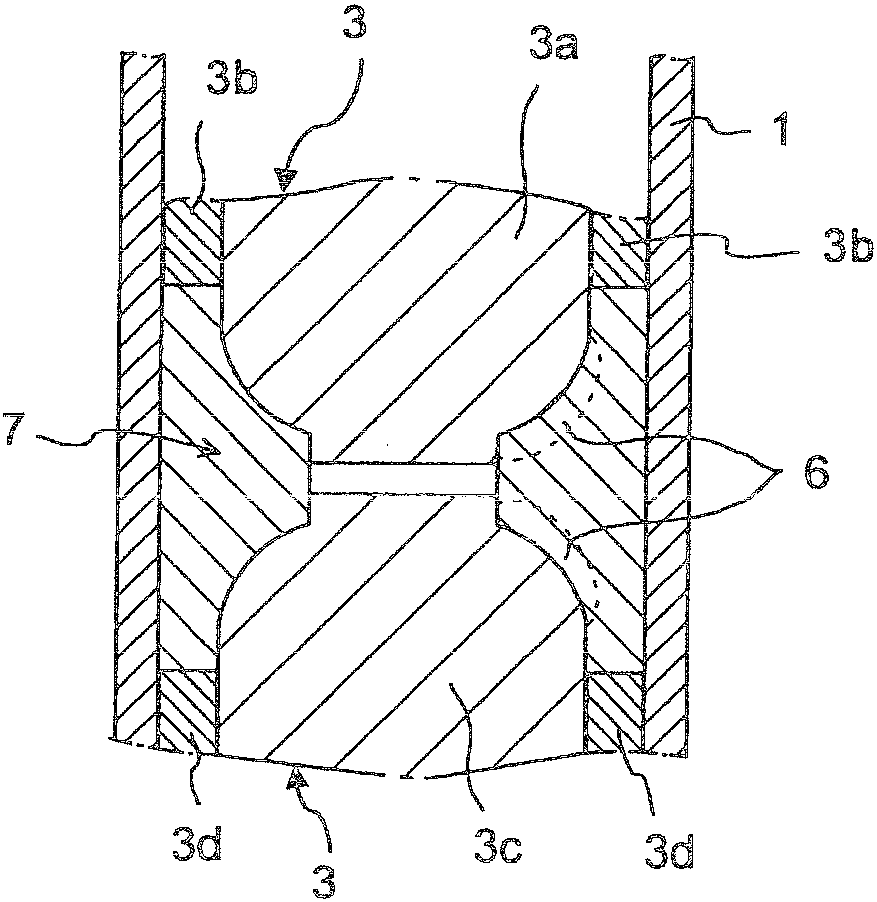

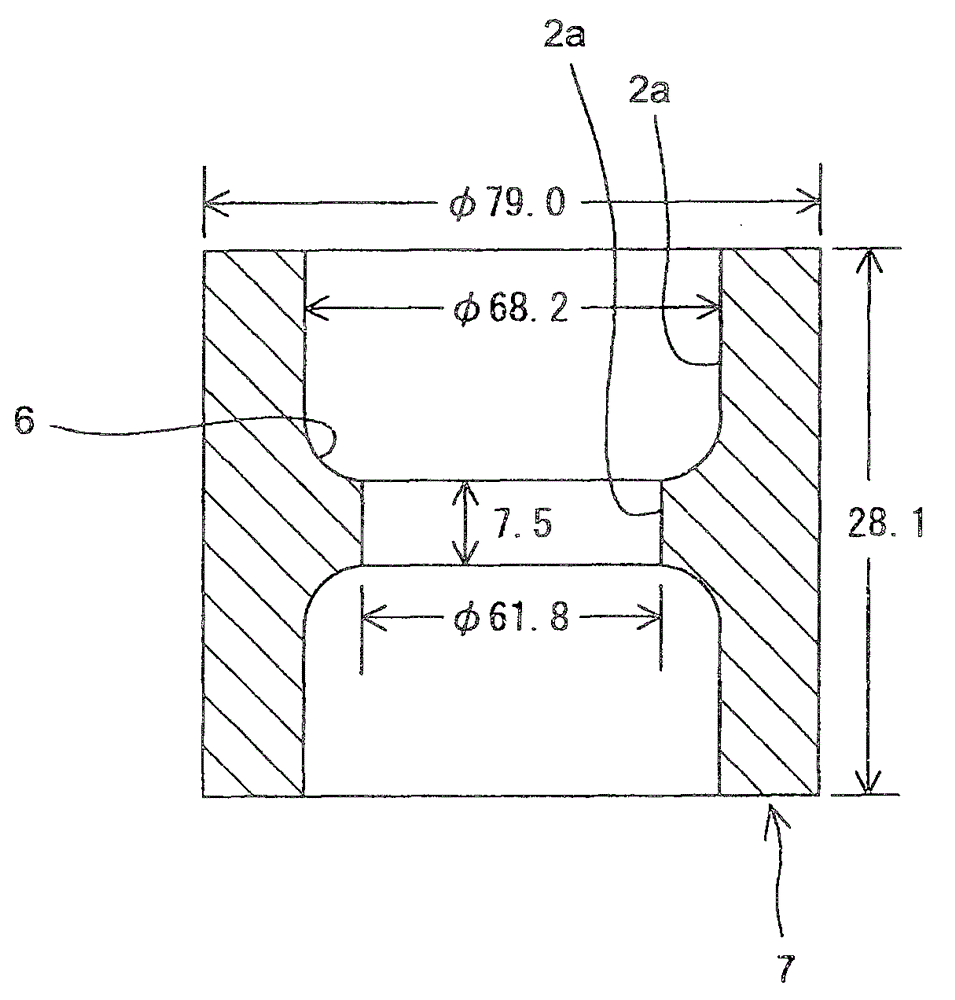

[0054] A test piece was produced in the same manner as in Example 1 except that a hot forged ring was produced instead of the steel pipe. The method of making the hot forging ring is as follows. First, the molten steel is oxidized and refined in an arc melting furnace, then reduced and refined in a ladle refining furnace (LF), and degassed by a circular vacuum degasser (RH) to reduce the oxygen content in the molten steel , Through the molten steel, steel ingots are manufactured by continuous casting. The steel ingot is hot-rolled as usual to form a steel material, and after that, the sheared billet is made into a hot forging ring with an outer diameter of φ80mm, a wall thickness of 8.7mm, and a width of 27.2mm by hot forging, and then the conventional spheroidizing heat is applied to them. Handling ready for hot forging rings. The outer and inner diameters of the hot-forged rings obtained as described above and composed of the test materials shown in Table 1 were machined t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com