A kind of tamsulosin sustained-release pellets and preparation method thereof

A technology of sustained-release pellets and tamsulosin, applied in the field of sustained-release pellets and its preparation for changing the release behavior of tamsulosin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 Tamsulosin sustained-release pellets and tablets (1000 preparation units)

[0016] The prescription of preparation and preparation method thereof are:

[0017] prescription

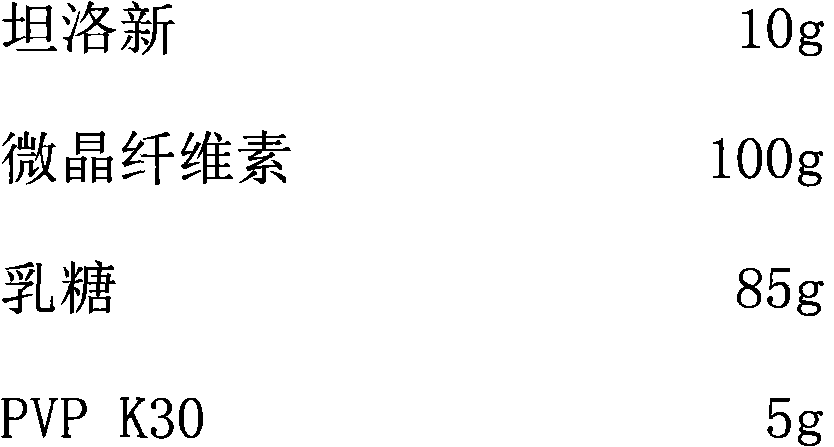

[0018] Pill heart:

[0019]

[0020] Coating:

[0021] Carbomer 8g

[0022] Ethylcellulose 9g

[0023] Triethyl citrate 3g

[0024] Preparation:

[0025] Take povidone and add 80% ethanol to dissolve, and use it as a binder for later use; put the components in other pellet formulations in an extrusion spheronizer, add a binder to prepare a pellet core, and dry it in a fluidized bed at 60°C;

[0026] Take the core of the ball, put it in the coating pan, spray the coating ingredients dissolved in acetone for coating, and dry for 1 hour after coating. Then dry at 40° C. for 12 hours to obtain sustained-release pellets.

[0027] Put the desustained-release pellets into capsules.

[0028] Or add microcrystalline cellulose and magnesium stearate to the above-mentioned pellets, mi...

Embodiment 2

[0030] Embodiment 2 Tamsulosin sustained-release pellets and tablets (1000 preparation units)

[0031] The prescription of preparation and preparation method thereof are:

[0032] prescription

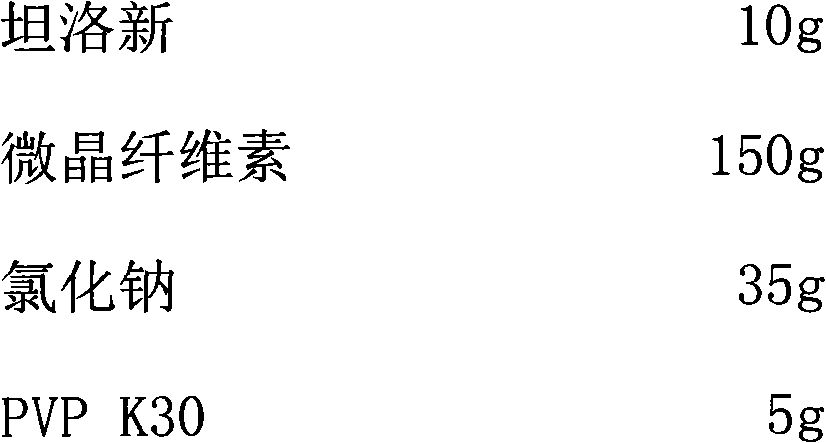

[0033] Pill heart:

[0034]

[0035] Coating:

[0036] Sodium alginate 15g

[0037] Ethyl cellulose 29g

[0039] Preparation:

[0040] Take povidone and add 80% ethanol to dissolve, and use it as a binder for later use; put the components in other pellet formulations in an extrusion spheronizer, add a binder to prepare a pellet core, and dry it in a fluidized bed at 60°C;

[0041] Take the core of the ball, put it in the coating pan, spray the coating ingredients dissolved in acetone for coating, and dry for 1 hour after coating. Then dry at 40° C. for 12 hours to obtain sustained-release pellets.

[0042] Put the desustained-release pellets into capsules.

[0043] Or add microcrystalline cellulose and magnesium stearate to the above-mentioned...

Embodiment 3

[0045] Embodiment 3 Tamsulosin sustained-release pellets and tablets (1000 preparation units)

[0046] The prescription of preparation and preparation method thereof are:

[0047] prescription

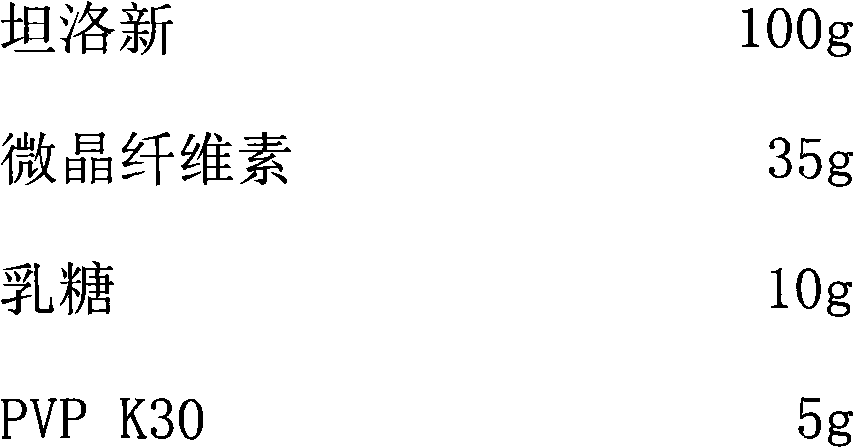

[0048] Pill heart:

[0049]

[0050] Coating:

[0051]

[0052] Preparation:

[0053] Take povidone and add 80% ethanol to dissolve, and use it as a binder for later use; put the components in other pellet formulations in an extrusion spheronizer, add a binder to prepare a pellet core, and dry it in a fluidized bed at 60°C;

[0054] Take the core of the ball, put it in the coating pan, spray the coating ingredients dissolved in acetone for coating, and dry for 1 hour after coating. Then dry at 40° C. for 12 hours to obtain sustained-release pellets.

[0055] Put the desustained-release pellets into capsules.

[0056] Or add microcrystalline cellulose and magnesium stearate to the above-mentioned pellets, mix, and press into tablets of suitable size.

[0057] The release ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com