Malodorous gas treatment system and method thereof

A malodorous gas and treatment system technology, which is applied in the direction of separation methods, chemical instruments and methods, and air quality improvement, can solve the problems of unsuitable high-concentration malodorous gas purification treatment, etc., and achieves compact structure, simple operation and maintenance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

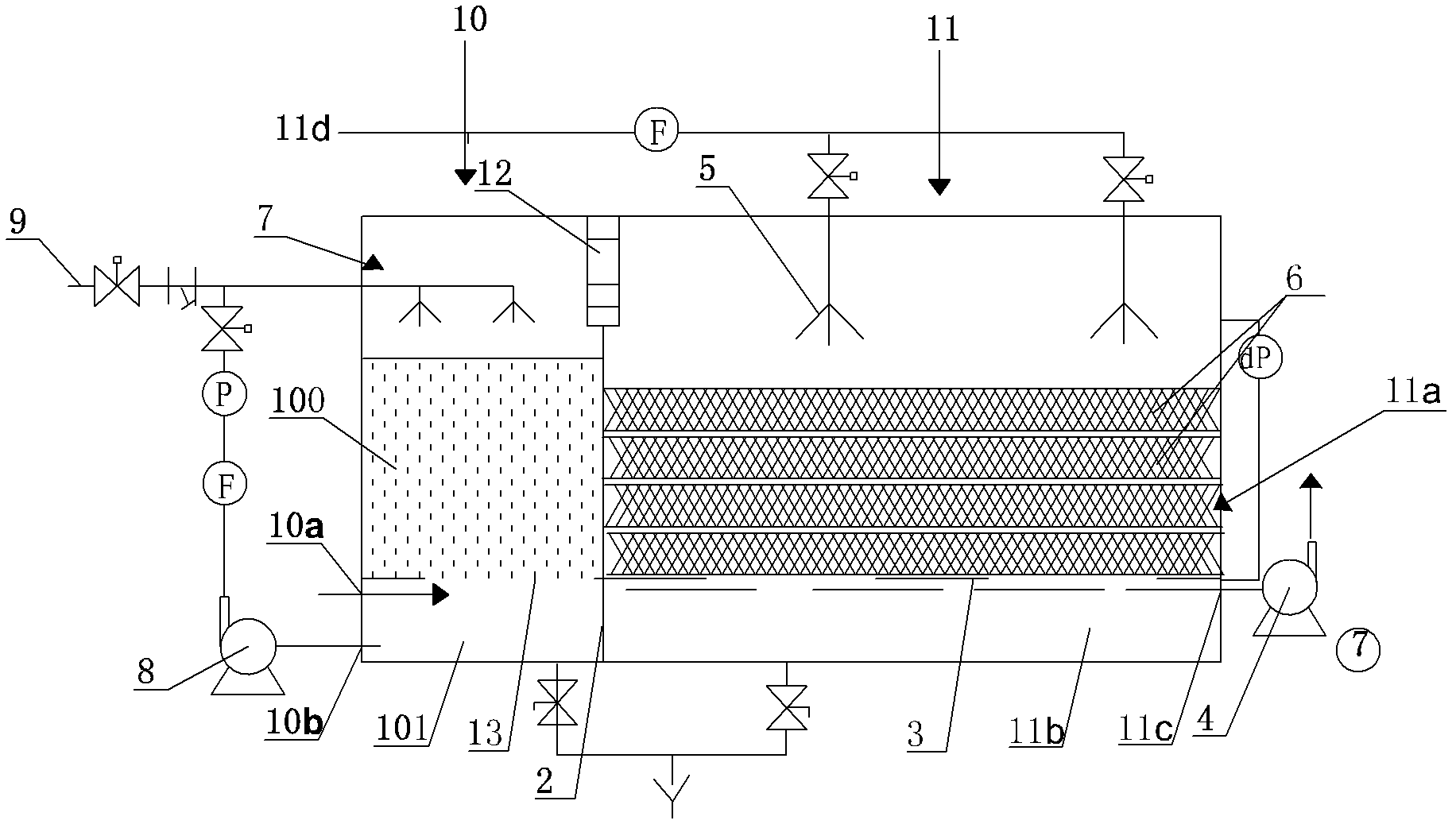

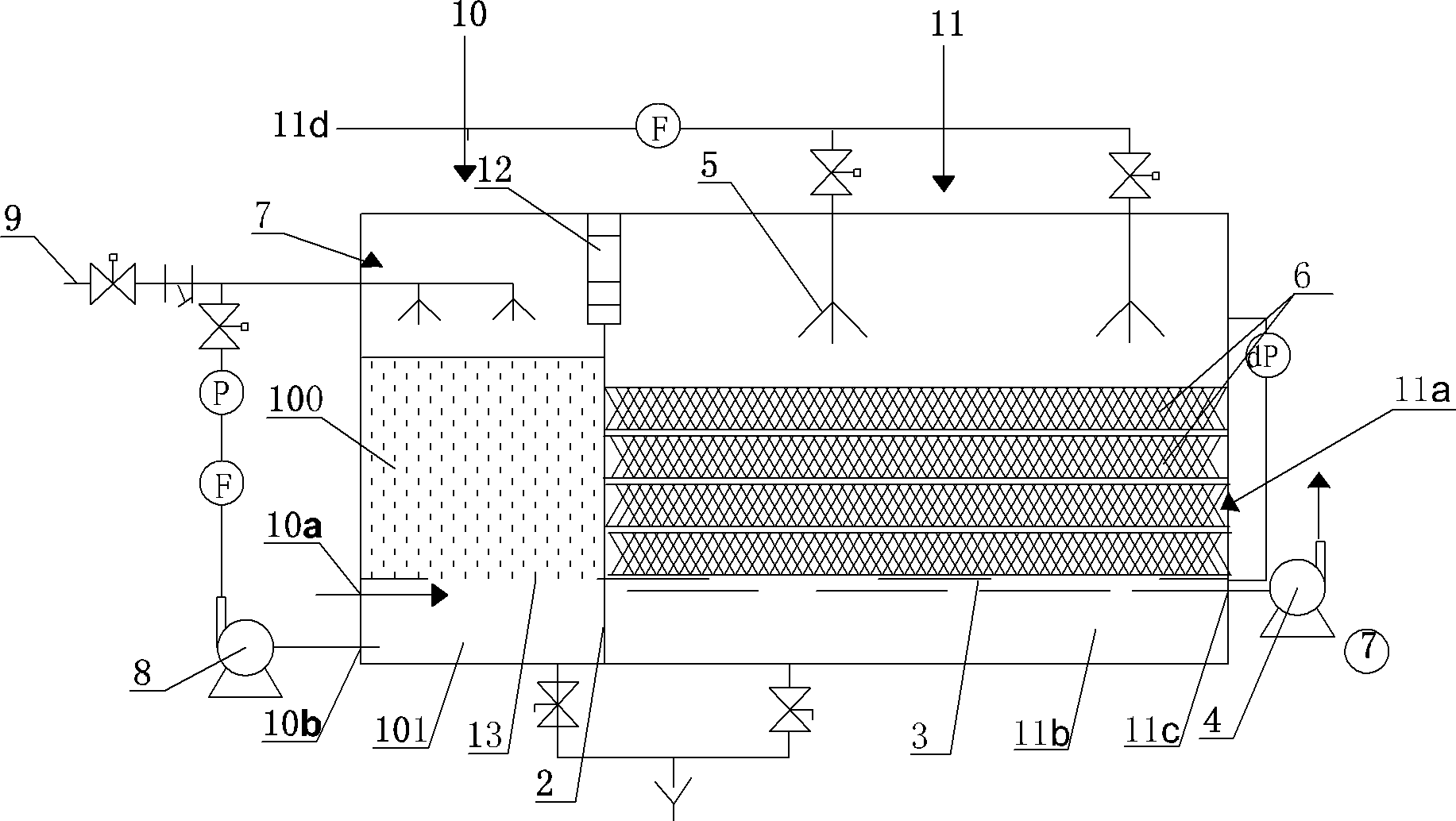

[0033] This embodiment provides a malodorous gas treatment system. Such as figure 1 As shown, the malodorous gas treatment system mainly includes a reaction vessel, which is divided into a first reaction chamber 10 and a second reaction chamber 11 side by side by a partition plate 2 placed therein, at the top of the partition plate 2 and the reaction vessel There is a gap 12 connecting the first reaction chamber 10 and the second reaction chamber 11 therebetween.

[0034] The first reaction chamber 10 is provided with a porous plate 13 , which divides the first reaction chamber 10 into a chemical washing humidity control area 100 located above and a detergent storage area 101 located below. A waste gas inlet 10a is provided on the upper part of the side wall of the first reaction chamber 10 where the detergent storage area 101 is located, and a detergent outlet 10b is provided below the waste gas inlet 10a. The malodorous gas treatment system of this example also includ...

Embodiment 2

[0039] This embodiment provides a method for applying the malodorous gas treatment system of Embodiment 1 to process malodorous gas containing hydrogen sulfide and ethanethiol.

[0040] The malodorous gas containing hydrogen sulfide and ethanethiol enters the upper part of the detergent storage area 101 through the waste gas inlet 10a, and enters the chemical washing humidity control area 100 through the perforated plate 13. The detergent in the detergent storage area 101 is sprayed on the upper part of the chemical washing humidity control area 100 through the detergent circulation pump 8, and the detergent is a weakly alkaline agent. The upward exhaust gas is mixed with the downward detergent, most of the hydrogen sulfide in the exhaust gas is removed, and the humidity is adjusted. The humidity-adjusted exhaust gas directly enters the biological reaction zone 11 a through the gap 12 . In the biological reaction zone 11a, after the waste gas passes through multi-layers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com