Selective catalytic reduction (SCR) denitrification device with heat pipe type air pre-heater

An air preheater, tubular technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the constraints of sustainable economic and social development, high investment, management and operating costs, and large operating conditions. problems, to achieve the effect of reducing flue gas ash accumulation, reducing system pressure loss, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

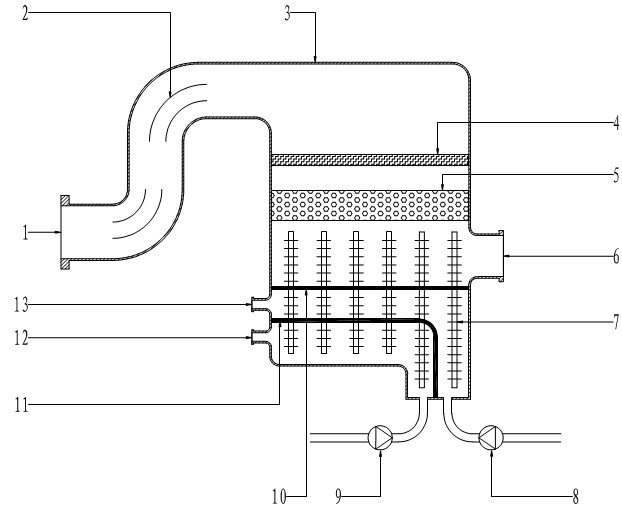

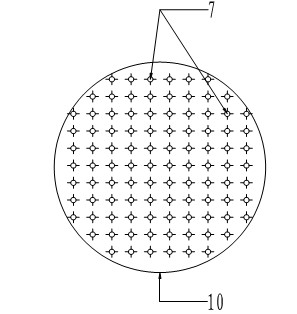

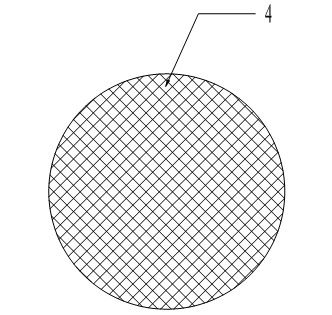

[0020] Such as figure 1 The shown SCR denitrification device with a heat pipe type air preheater includes a deflector 2 and a rectifier 4 placed in the SCR denitrification reactor 3 , and a catalyst layer 5 arranged at the lower part of the rectifier 4 . A plurality of heat pipes 7 are arranged below the catalyst layer 5 in the SCR denitration reactor 3, and the heat pipes 7 are evenly distributed on the support plate 10 of the SCR denitration reactor 3, and are fixed in the SCR denitration reactor 3 by the support plate 10. At the same time, the support plate 10 and the wind zone partition 11 separate the SCR denitrification reactor 3 into an upper reaction zone, a primary wind zone, and a secondary wind zone. A flue gas outlet 6 is provided on the upper side of the SCR denitration reactor 3 opposite to the flue gas inlet 1 .

[0021] The lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com