Water purification method capable of realizing in-situ preparation and in-situ regeneration of catalyst and catalyzing zone to oxidize organic micropollutants

A technology of organic pollutants and ozone oxidation, which is applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc. problems, to achieve excellent ability to catalyze the ozone oxidation process, good refractory organic pollutants, and avoid the deactivation of active functional groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

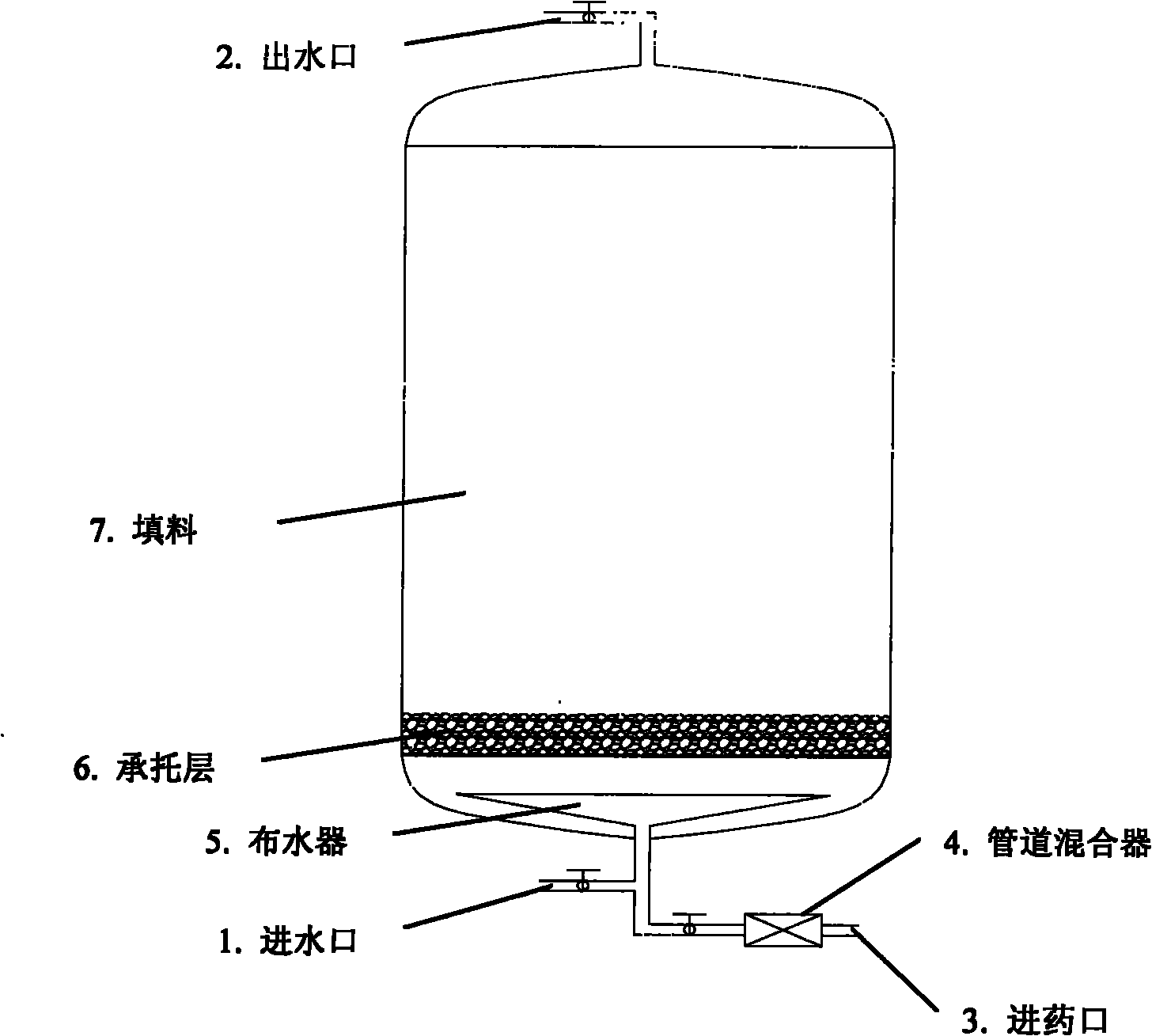

[0028] Preparation of copper-manganese composite oxide / support matrix catalyst: use diatomaceous earth as the support matrix and fill in such as figure 1 In the columnar reactor shown; prepare 0.075mol / L CuCl solution; prepare 0.050mol / LNaOH and 0.025mol / L KMnO 4 mixed solution. Mix an equal flow of CuCl solution and an equal flow of NaOH and KMnO 4 The mixed solution is pumped into the figure 1 For the reactor shown, ensure that the load substrate is completely submerged. Then pump clean water into the reactor and let it flow out slowly until the concentration of copper and manganese in the effluent is lower than the national drinking water quality standard.

Embodiment 2

[0030] Preparation of copper-manganese composite oxide / loaded matrix catalyst: use quartz sand as the loaded matrix to fill in such as figure 1 In the column reactor shown; prepare 0.075mol / L CuSO 4 Mixed solution with 0.075mol / L CuCl; prepare 0.20mol / L KOH and 0.025mol / L KMnO 4mixed solution. equal flow of CuSO 4 and CuCl mixed solution and equal flow of KOH and KMnO 4 The mixed solution is pumped into the figure 1 For the reactor shown, ensure that the load substrate is completely submerged. Then pump clean water into the reactor and let it flow out slowly until the concentration of copper and manganese in the effluent is lower than the national drinking water quality standard.

Embodiment 3

[0032] Preparation of copper-manganese composite oxide / supported substrate catalyst: use ceramsite as the loaded substrate and fill in such as figure 1 In the columnar reactor shown; prepare 0.075mol / L MnSO 4 Mixed solution with 0.075mol / L CuCl; prepare 0.175mol / L KOH and 0.050mol / L KMnO 4 mixed solution. MnSO 4 and CuCl mixed solution and equal flow of KOH and KMnO 4 The mixed solution is pumped into the figure 1 For the reactor shown, ensure that the load substrate is completely submerged. Then pump clean water into the reactor and let it flow out slowly until the concentration of copper and manganese in the effluent is lower than the national drinking water quality standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com