Tundish covering flux

A technology of covering agent and tundish, which is applied in the field of tundish covering agent, which can solve the problems of poor spreadability and heat preservation, increase the granularity of covering agent, reduce the density of covering agent, etc., and achieve improved purity, suitable melting point and good spreading sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

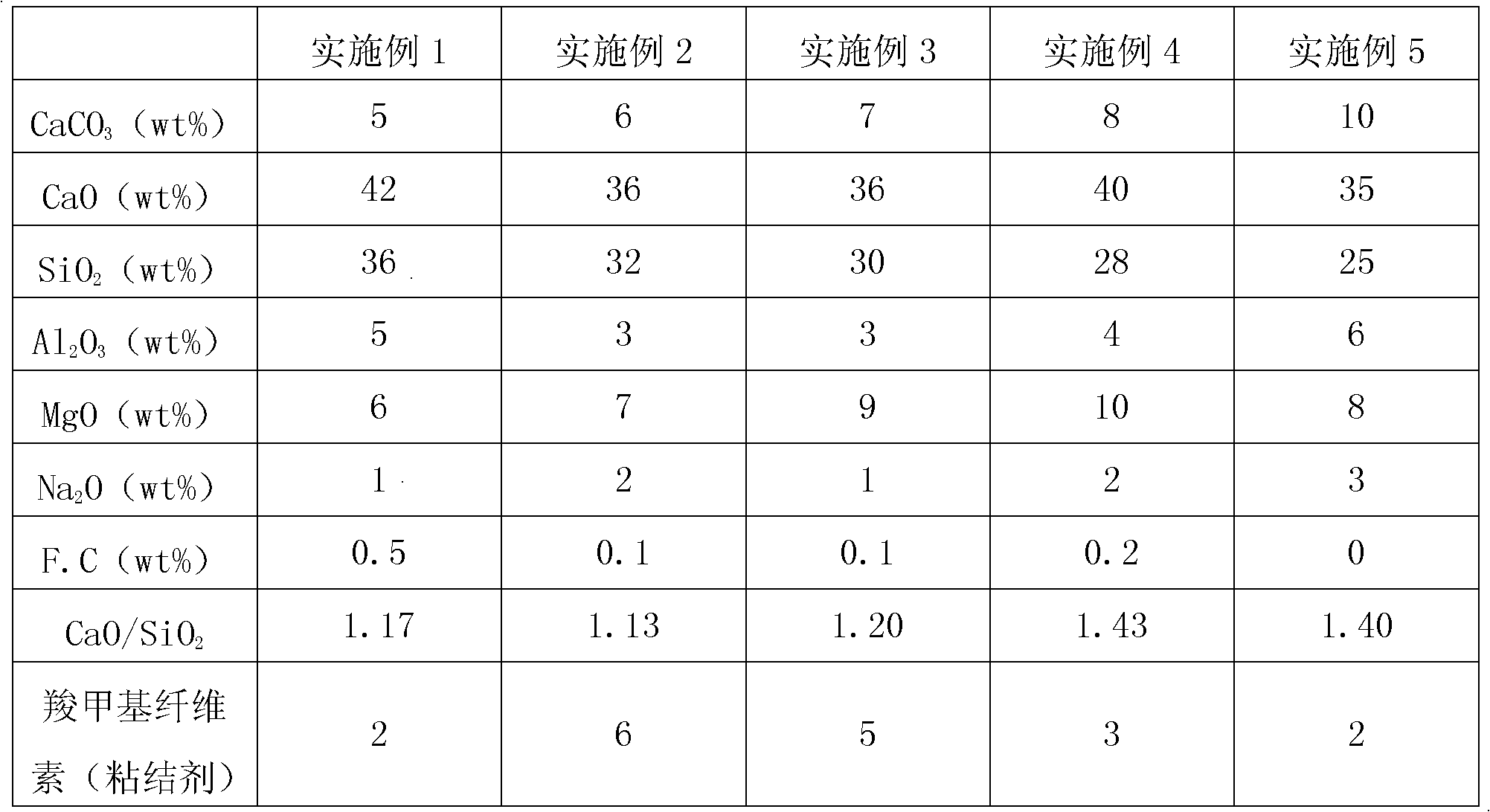

[0033] See Table 3 for the mass percentage distribution of each component of the tundish covering agent of Examples 1-5 of the present invention.

[0034] Table 3. (The balance is unavoidable impurities)

[0035]

[0036]

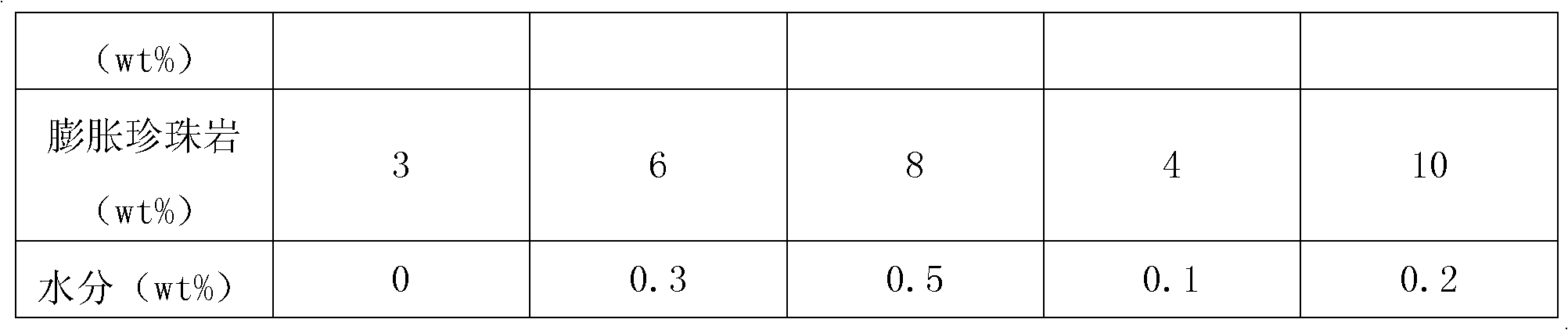

[0037] The physical performance parameters of the tundish covering agents of Examples 1-5 of the present invention are shown in Table 4.

[0038] Table 4.

[0039] Example

Melting point (°C)

Viscosity (Pa.S)

Bulk density (g / cm 3 )

Granularity (mm)

1

1270

1.10

0.96

0.5mm

2

1290

1.19

0.85

0.4mm

3

1300

1.25

0.73

0.3mm

4

1305

1.33

0.62

0.2mm

5

1311

1.50

0.50

0.1mm

[0040] In the above-mentioned Examples 1-5, when the first continuous casting furnace is poured and the tundish is 35 tons, the tundish covering agent is dropped into the two preheating holes and the castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com