Automatic laser engraving and code reading equipment for oil spraying nozzle

A technology of laser engraving and fuel injectors, applied in engraving, decorative art, processing models, etc., can solve the problem that mass production cannot be monitored effectively in real time, the model, specification and production information cannot be well controlled, and cannot be one-to-one Correspondence and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

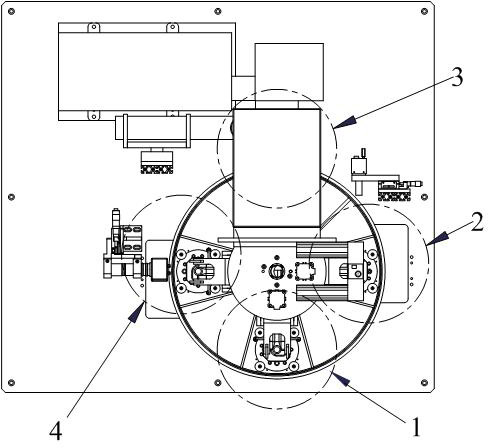

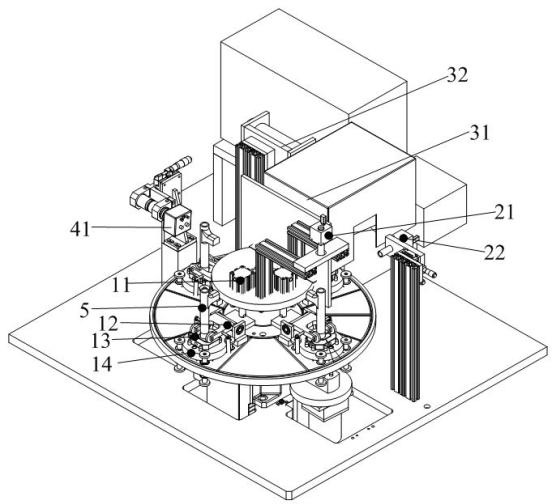

[0016] like figure 1 As shown, the automatic laser engraving and code reading equipment for fuel injectors includes a frame and an index plate installed on the frame. The index plate is equipped with a loading and unloading station device 1, an ID identification station device 2, Laser engraving station device 3 and two-dimensional code detection station device 4, such as figure 2 As shown, the loading and unloading station device 1 includes a clamping mechanism 12, a cylinder 11 and a fixed block 13, the piston rod of the cylinder 11 is connected to the clamping mechanism 12, and the fixed block 13 is arranged under the clamping mechanism 12, and the fixed block 13 passes The positioning rotation axis is installed on the lifting rotating platform 14, and the lifting rotating platform 14 is installed on the lifting platform lifting device;

[0017] The ID identification station device 2 includes a CCD camera 21 located directly above and a CCD camera 22 located on the side; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com