Preparation method of graphene material

A graphene and graphite technology, applied in the field of graphene material preparation, can solve the problems of long chemical methods, troublesome graphene, etc., achieve high-quality preparation and overcome many defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

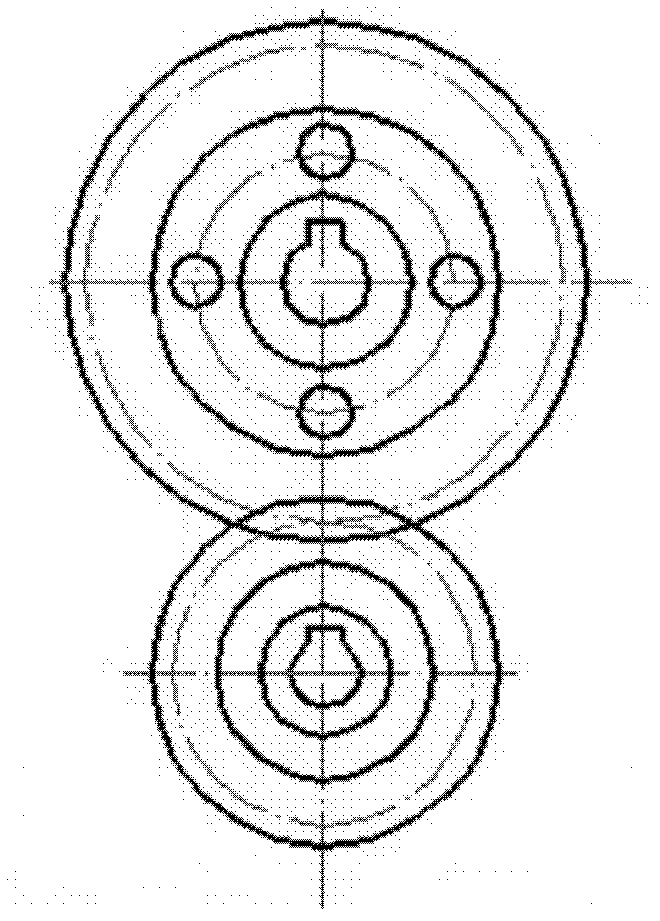

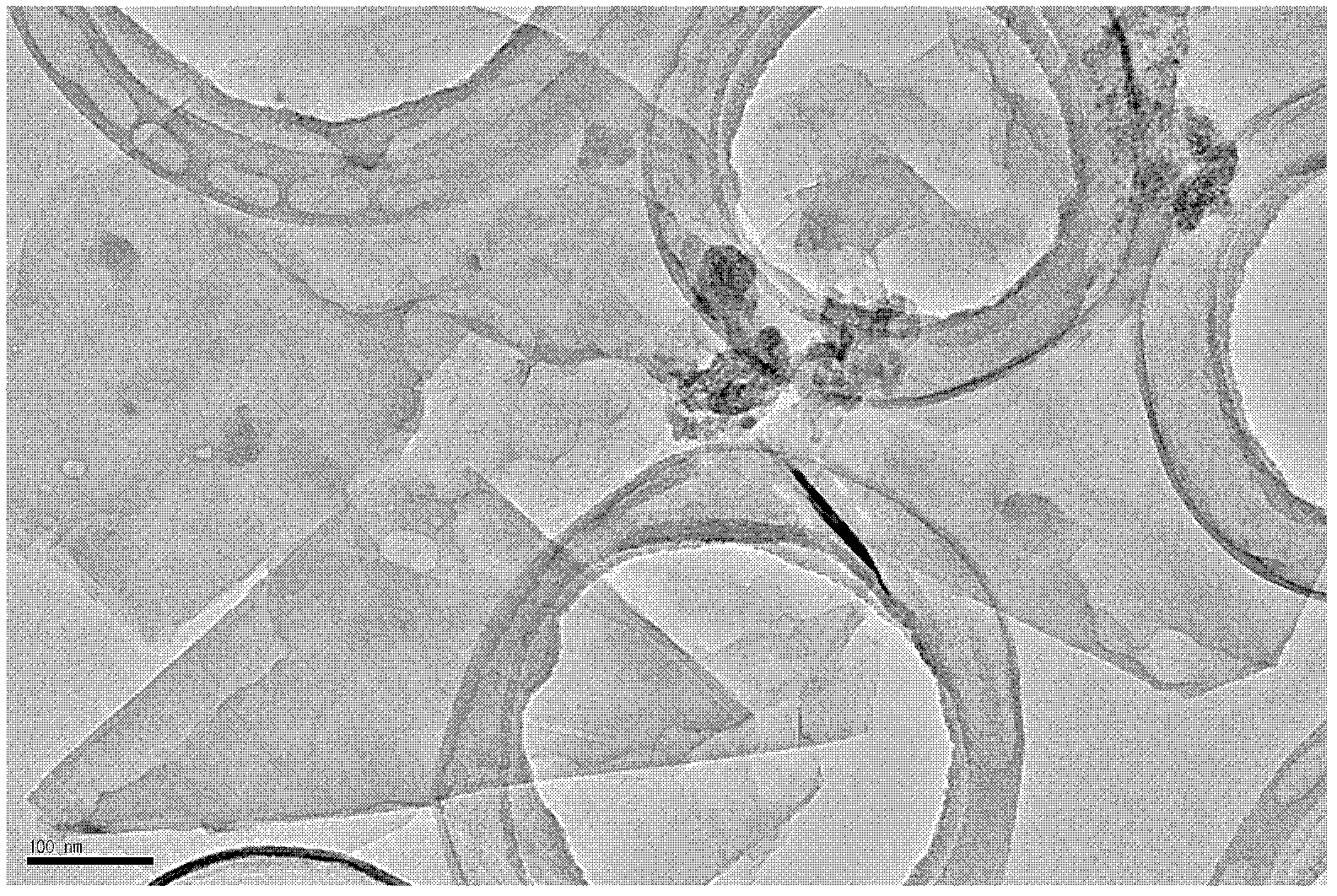

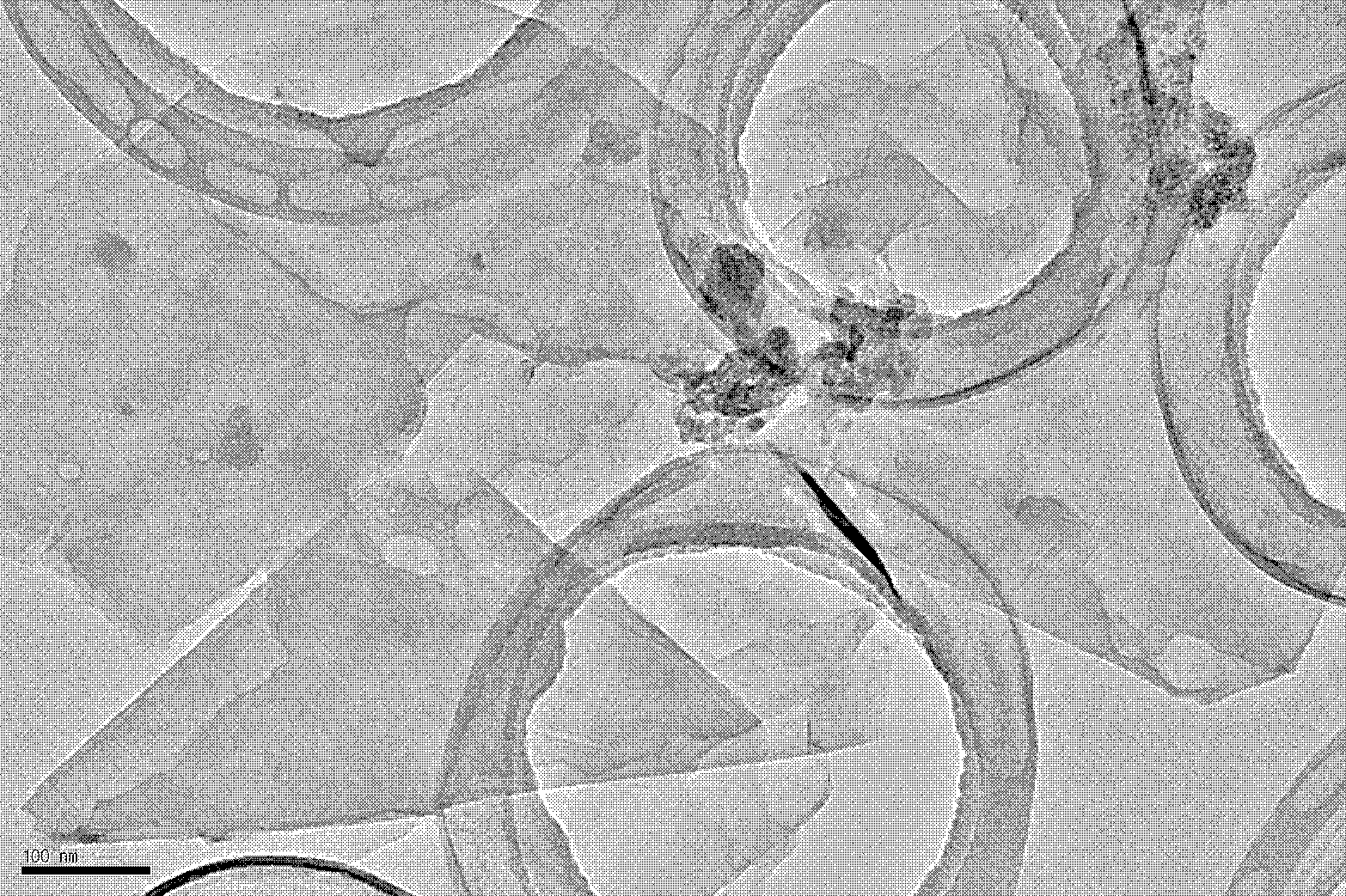

[0018] Embodiment: Graphite powder and benzaldehyde are formed suspension according to the solubility of 2mg / ml, put into the container that gear set is installed, gear speed is about 50 revolutions, rotate 5 hours, take out slurry, ultrasonic treatment 0.5 hour, carry out Centrifuge at a high speed at 4000 rpm for 5 minutes, so that the unstripped and torn graphite particles and graphite flakes are precipitated at the bottom of the centrifuge tube or centrifuge cylinder by centrifugation, and the upper layer solution is the single-layer graphene and multi-layer graphene solution. Graphene in the obtained upper layer solution is carried out transmission electron microscope scanning, figure 2 TEM pictures of prepared graphene. figure 1 It is a schematic diagram of the gear set used in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com