Purifying method for high-purity silica sol

A silica sol, high-purity technology, applied in the direction of silicon oxide, silicon dioxide, etc., to achieve the effect of good sedimentation performance, good water solubility, and short purification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

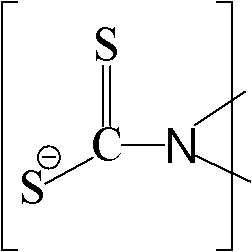

[0043] Strong-acid cation exchange resins have exchange groups -SO on the resin skeleton 3 The cation exchange resin for H is Dowex 50W; the strong base anion exchange resin has an exchange group -N on the resin skeleton. + (CH 3 ) 3 Cl - or -N + (CH 3 ) 3 C 2 h 4 OHCl - Anion exchange resin, choose Dowex 1.

[0044] The silicon dioxide content in the silica sol to be purified is 20%, the particle diameter is 40nm, the metal ion content is about 3000ppm, and the anion content is about 300ppm. The purification method steps of high-purity silica sol are as follows:

[0045] (1) Regenerate the strong acid type cation exchange resin and the strong base type anion exchange resin respectively;

[0046] (2) Mix the regenerated strong acid type cation exchange resin and the strong base type anion exchange resin in a volume ratio of 10:1 to obtain a strong acid and strong base mixed resin, and pack into a container with cooling, heating and stirring;

[0047] (3) adding the...

Embodiment 2

[0052] Strong-acid cation exchange resins have exchange groups -SO on the resin skeleton 3 The cation exchange resin for H is Amberlite IR-120; the strong base anion exchange resin has an exchange group -N on the resin skeleton. + (CH 3 ) 3 Cl - or -N + (CH 3 ) 3 C 2 h 4 OHCl - Anion exchange resin, choose AmberliteIRA-400.

[0053] The silicon dioxide content in the silica sol to be purified is 40%, the particle size is 30nm, the metal ion content is about 2000ppm, and the anion content is about 650ppm. The purification method steps of high-purity silica sol are as follows:

[0054] (1) Regenerate the strong acid type cation exchange resin and the strong base type anion exchange resin respectively;

[0055] (2) Mix the regenerated strong acid type cation exchange resin and the strong base type anion exchange resin in a volume ratio of 3:1 to obtain a strong acid and strong base mixed resin, and pack into a container with cooling, heating and stirring;

[0056] (3)...

Embodiment 3

[0061] Strong-acid cation exchange resins have exchange groups -SO on the resin skeleton 3 The cation exchange resin of H is Amberlyst 15; the strong base anion exchange resin has an exchange group -N on the resin skeleton. + (CH 3 ) 3 Cl - or -N + (CH 3 ) 3 C 2 h 4 OHCl - The anion exchange resin used is Amberlite IRA-410.

[0062] The silicon dioxide content in the silica sol to be purified is 30%, the particle size is 10nm, the metal ion content is about 3000ppm, and the anion content is about 600ppm. The purification method steps of high-purity silica sol are as follows:

[0063] (1) Regenerate the strong acid type cation exchange resin and the strong base type anion exchange resin respectively;

[0064] (2) mix the regenerated strong acid type cation exchange resin and the strong base type anion exchange resin in a volume ratio of 5:1 to obtain a strong acid and strong base mixed resin, and pack into a container with cooling, heating and stirring;

[0065] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com