Removing method of high undissolved substances and low-grade solid potassium ore undissolved substances

A solid potash ore, low-grade technology, applied in potash fertilizers, alkali metal chlorides, inorganic fertilizers, etc., can solve the problems of difficulty in large-scale development and utilization of resources, difficult separation of minerals and insolubles, poor economic benefits, etc. The amount of resources that can be processed and utilized, the effect of improving the degree of development and utilization, and improving the utilization rate of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

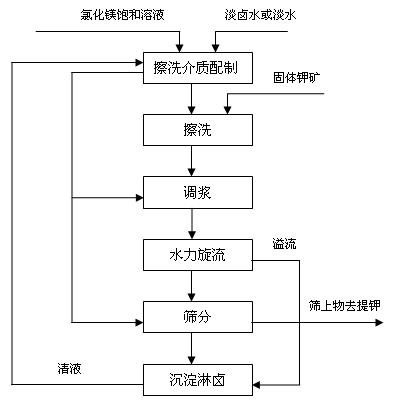

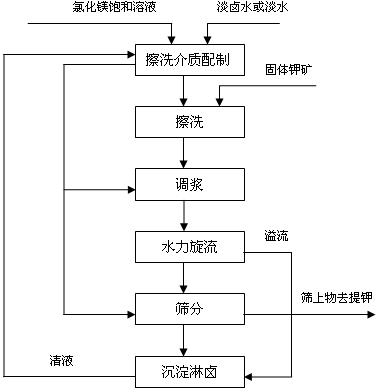

[0006] Embodiment 1: get 100 tons of high insoluble matter solid potash ore, its mass component is potassium chloride 4.14%, insoluble matter is 49.59%, sodium chloride etc. 46.27%; With magnesium chloride saturated solution and light brine with weight ratio 1: The ratio of 0.05 is mixed at normal temperature and normal pressure for 5Min, and 150 tons of scrubbing medium is prepared; the solid potassium ore is mixed with the scrubbing medium prepared, and the slurry weight percentage concentration after mixing is 40%, and the mixed material is mixed at 40 rpm. The rotation speed of Min is forced to stir and scrub, and the scrubbing time is 20min; the slurry that has been scrubbed is adjusted to 20% by weight with a prepared scrubbing medium; Cyclone separation, the pressure at the inlet of the cyclone is controlled at 0.10Mpa; the bottom flow slurry of the cyclone is adjusted to 20% by weight with the prepared scrubbing medium, and then pumped into a multi-layer vibrating scree...

Embodiment 2

[0007] Embodiment 2: Get 100 tons of high insoluble solid potassium ore, its mass components are potassium chloride 3.51%, insoluble matter is 60.12%, sodium chloride etc. 36.37%; Use magnesium chloride saturated solution and fresh water with weight ratio 1:0.1 The ratio is mixed at normal temperature and pressure for 5Min to prepare 43 tons of scrubbing medium; the solid potassium ore is mixed with the prepared scrubbing medium, and the mixed slurry weight percentage concentration is 70%, and the mixed material is 120 turns / Min The speed of rotation is forced to stir and scrub, and the scrubbing time is 90min; the slurry that has been scrubbed is adjusted to 50% by weight with the scrubbing medium prepared; flow separation, the pressure at the inlet of the cyclone is controlled at 0.20Mpa; use the prepared scrubbing medium to adjust the concentration of the slurry weight percentage to 50%, and then pump it into a multi-layer vibrating screen for screening and separation. 32 t...

Embodiment 3

[0008] Embodiment 3: get 100 tons of high insoluble matter solid potash ore, its quality component is potassium chloride 6.5%, insoluble matter is 40.3%, sodium chloride etc. 53.2%; Use magnesium chloride saturated solution and fresh water with weight ratio 1:0.08 The ratio is mixed at normal temperature and pressure for 5Min, and 100 tons of scrubbing medium is prepared; the solid potassium ore is mixed with the scrubbing medium prepared, and the mixed slurry weight percentage concentration is 50%, and the mixed material is 80 rpm / Min The speed of rotation is forced to stir and scrub, and the scrubbing time is 60 minutes; the scrubbed slurry is adjusted to 30% by weight with the prepared scrubbing medium; the slurry after slurry is spun in a cyclone For flow separation, the pressure at the inlet of the cyclone is controlled at 0.15Mpa; the bottom flow slurry of the cyclone is adjusted to 40% by weight with the prepared scrubbing medium, and then pumped into a multi-layer vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com