MBBR (Moving Bed Biofilm Reactor) packing material negative pressure and positive pressure conveying method and device

A negative pressure and air pressure technology is applied in the field of realizing bladeless MBBR packing conveying device, which can solve the problems of packing crushing, microbes on the packing surface falling off, unable to play the role of propulsion and conveying, etc., so as to improve efficiency and function. Good effect, the effect of improving aerobic biochemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

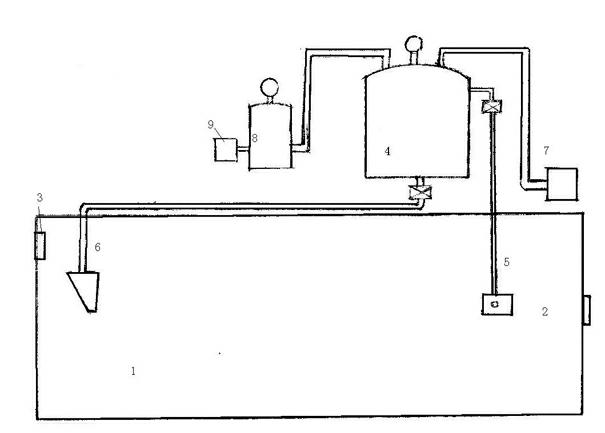

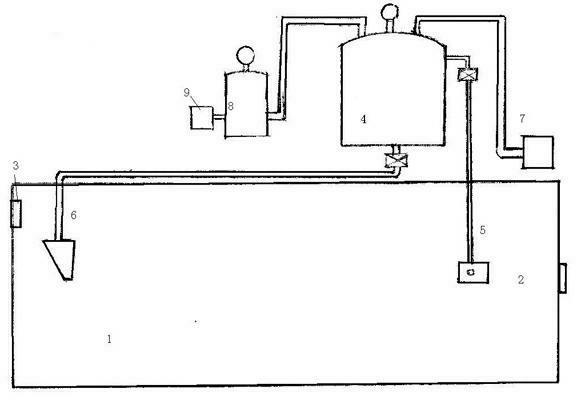

[0015] The use of the present invention makes the filler flow orderly in water, which is an important factor for the success of the MBBR process. The traditional paddle-type underwater propulsion and agitator are difficult to complete. It is not easy to meet the technical requirements of evenly distributing the filler in the pool when it is transported at the water end. The invention proposes the principle of negative pressure lifting, pressurized water blowing and conveying: the filler is sucked into the vacuum tank by using the negative pressure principle, and then the water and filler are blown out of the vacuum tank together by compressed air or pressurized into the tank and transported to a distant place through the pipeline.

[0016] During the specific implementation of the present invention, the collection cover is connected with the vacuum tank through the pipeline, the vacuum degree of the vacuum tank is generally 60-80Kpa, the vacuum tank is connected with the air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com