Microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and preparation steps, which is applied in the field of ultra-low temperature sintered microwave dielectric ceramics and its preparation, and can solve problems such as high sintering temperature, high absolute value of the temperature coefficient of resonance frequency, and inability to co-fire low-melting point electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

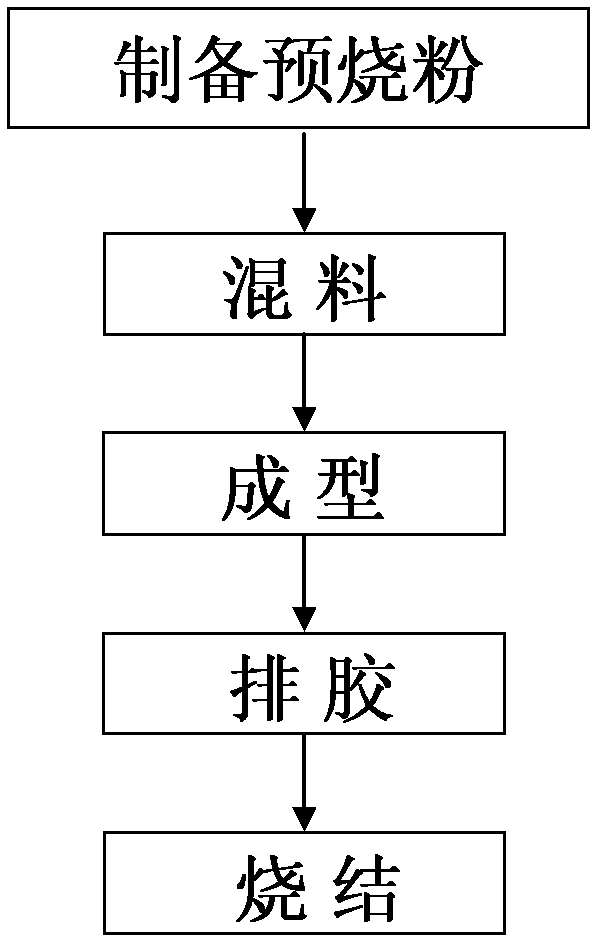

Method used

Image

Examples

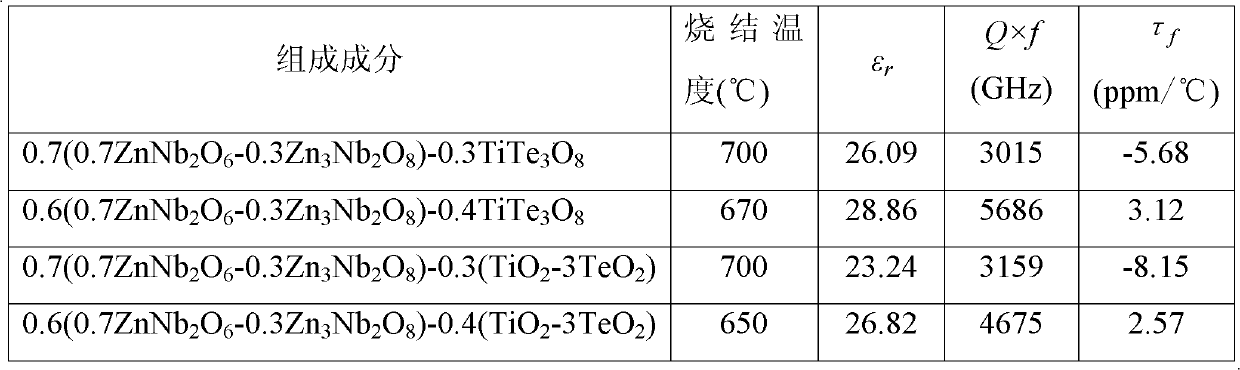

Embodiment 1

[0018] This embodiment is a microwave dielectric ceramic. The microwave dielectric ceramic is based on analytically pure ZnNb 2 o 6 , 99.9% ZnO and Nb 2 o 5 and TiO with a purity of 99.8% and 99.9% respectively 2 and TeO 2 As the starting material, according to (1-x)(0.7ZnNb 2 o 6 -0.3Zn 3 Nb 2 o 8 )-xTiTe 3 o 8 (where x = 0.3) stoichiometric formulation.

[0019] This embodiment also proposes a method for preparing the microwave dielectric ceramic, and its specific preparation steps are:

[0020] Step 1, prepare Zn 3 Nb 2 o 8 Burnt powder. ZnO and Nb 2 o 5 , Weighed in a molar ratio of 3:1. The weighed ZnO powder and Nb 2 o 5 The powder is placed in a polyethylene ball mill jar. Add absolute ethanol according to the mass ratio of powder and ethanol in the range of 1:1 to 2:1, and ball mill on a ball mill for 12 hours. The ball-milled wet material was placed in an oven, and dried at 100° C. for 6 hours to obtain a dry powder. Grind the dry powder into a...

Embodiment 2

[0028] This embodiment is a microwave dielectric ceramic. The microwave dielectric ceramic is based on analytically pure ZnNb 2 o 6 , 99.9% ZnO and Nb 2 o 5 and TiO with a purity of 99.8% and 99.9% respectively 2 and TeO 2 As the starting material, according to (1-x)(0.7ZnNb 2 o 6 -0.3Zn 3 Nb 2 o 8 )-xTiTe 3 o 8 (where x = 0.4) stoichiometric formulation.

[0029] This embodiment also proposes a method for preparing the microwave dielectric ceramic, and its specific preparation steps are:

[0030] Step 1, prepare Zn 3 Nb 2 o 8 Burnt powder. ZnO and Nb 2 o 5 , Weighed in a molar ratio of 3:1. The weighed ZnO and Nb 2 o 5Put it in a polyethylene ball mill jar, add absolute ethanol according to the mass ratio of powder to ethanol in the range of 1:1 to 2:1, and mill on a ball mill for 16 hours. The ball-milled wet material was placed in an oven, and dried at 80° C. for 8 hours to obtain a dry powder. Grind the dry powder into a powder in an agate mortar. T...

Embodiment 3

[0038] This embodiment is a microwave dielectric ceramic. The microwave dielectric ceramic is based on analytically pure ZnNb 2 o 6 , 99.9% ZnO and Nb 2 o 5 and TiO with a purity of 99.8% and 99.9% respectively 2 and TeO 2 As the starting material, according to (1-x)(0.7ZnNb 2 o 6 -0.3Zn 3 Nb 2 o 8 )-x(TiO 2 -3TeO 2 ) (wherein x=0.3) stoichiometric dosage ratio batching.

[0039] This embodiment also proposes a method for preparing the microwave dielectric ceramic, and its specific preparation steps are:

[0040] Step 1, prepare Zn 3 Nb 2 o 8 Burnt powder. ZnO and Nb 2 o 5 , Weighed in a molar ratio of 3:1. The weighed ZnO and Nb 2 o 5 Put it in a polyethylene ball mill jar, add absolute ethanol according to the mass ratio of powder to ethanol in the range of 1:1 to 2:1, and mill on a ball mill for 20 hours. The ball-milled wet material was placed in an oven, and dried at 60°C for 10 hours to obtain a dry powder. Grind the dry powder into a powder in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com