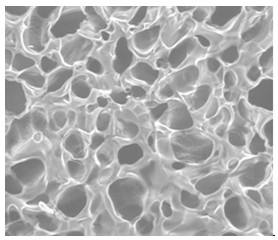

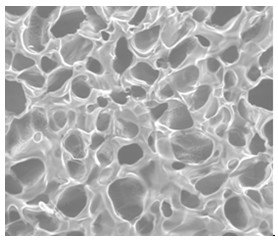

Method for preparing porous chitosan scaffold

A technology of porous scaffold and chitosan, applied in the field of preparation of chitosan porous scaffold, can solve problems such as poor connectivity, and achieve the effects of improving porosity, simple operation and enhancing connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of chitosan porous support, comprises the steps:

[0032] (1) Preparation of solution

[0033] Preparation is dissolved with the chitosan acid solution of 0.15g ammonium acetate:

[0034] First measure 1ml of acetic acid and add it to a 100ml volumetric flask to make up the volume to make a 1% (V / V) acetic acid solution;

[0035] Weigh 0.15g of ammonium acetate and add it to 1% (V / V) acetic acid solution, then weigh 3g of chitosan, and add 0.15g of ammonium acetate to the 1% (V / V) acetic acid solution;

[0036] To prepare a 1% (v / v) glutaraldehyde solution:

[0037] Measure 1ml of pure glutaraldehyde and add distilled water to make up to 100ml, store at 4°C for later use;

[0038] (2), Freeze drying

[0039] Weigh 0.2ml of the 1% (v / v) glutaraldehyde solution obtained in step (1), and add it into the chitosan acid solution in which 0.15g of ammonium acetate is dissolved in step (1), after stirring for 15min, put The stirred solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com