High precision titanium alloy resistance heating furnace

A technology of resistance heating and titanium alloy, which is applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of high scrap rate, poor thermal characteristics, and inability to meet the needs of titanium alloy heating or heat treatment, so as to reduce scrap rate and increase temperature The effect of fast speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

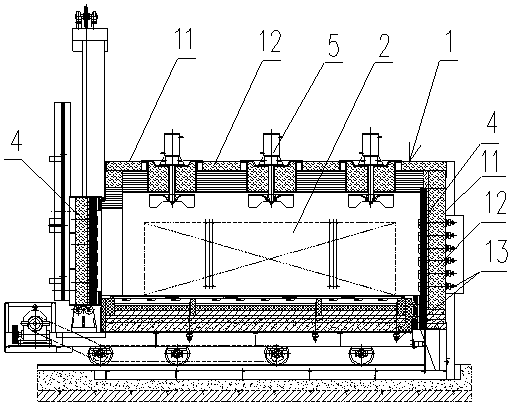

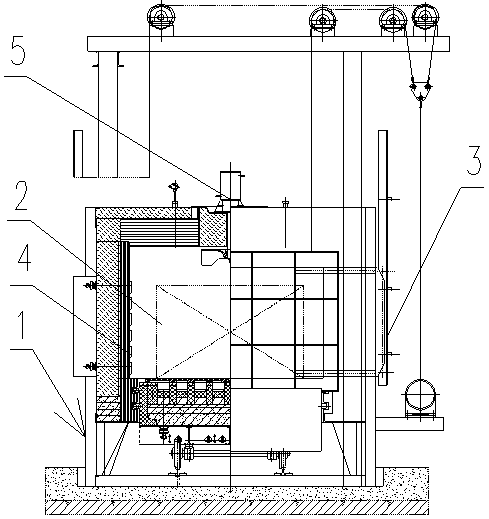

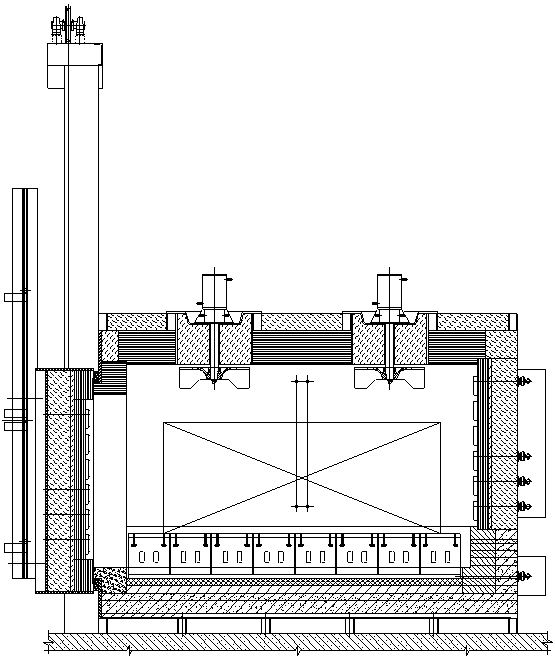

[0021] like figure 1 , 2 Among them, the high-precision titanium alloy resistance heating furnace of the present invention is used for conventional forging heating of titanium alloys, high-temperature forging heating, and annealing, solid solution and aging heat treatment of different grades of titanium alloys, including a furnace body 1 and a heating controller. Furnace body 1 composed of six side panels above, below, left, right, front and rear, the cavity in the middle forms a furnace 2, and a movable furnace door 3 is arranged on at least one of the side panels. The device drives down to rotate or move up and down to cooperate with the furnace mouth door opening on the side panel of the body of heater 1 to close.

[0022] On the inside of the six side panels of the furnace body 1, electric heaters 4 are provided, which generate heat to heat the furnace chamber 2 after being energized, and the heating controller controls the power on or off of the electric heater 4, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com