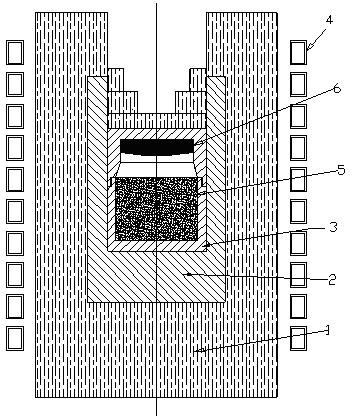

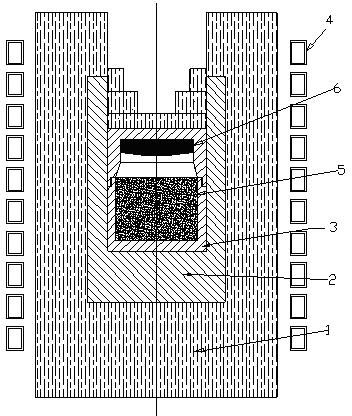

Double-crucible device for growing single crystals through induction heating physical vapor phase transfer

A technology of physical vapor transmission and induction heating, which is applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high cost, achieve the effects of prolonging service life, simplifying process and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A silicon carbide single crystal with a diameter of 6 inches was grown using the device of the present invention and the induction heating physical vapor transport method. Two sets of coaxial high-purity graphite crucibles (referred to as "double crucibles") are used. The inner diameter of the outer crucible is 200mm, the outer diameter is 250mm, the outer height is 300mm, and the inner cavity height is 250mm; the inner crucible is only used to hold raw materials (put At the bottom of the crucible) and seed crystal (installed on the inner surface of the crucible lid), the inner diameter is 160 mm, the outer diameter is 180 mm, the outer height is 160 mm, and the inner cavity height is 120 mm. The inner crucible is coaxially placed on the bottom of the outer crucible, and the inner crucible is sealed with a crucible cover, while the outer crucible does not have a crucible cover, so that the inner crucible can be taken out easily. After the growth is over, take out the in...

Embodiment 2

[0017] An aluminum nitride single crystal with a diameter of 1 inch is grown by using the device of the present invention and the induction heating physical vapor transport method. Two sets of coaxial tantalum crucibles (referred to as "double crucibles") are used. The inner diameter of the outer crucible is 41 mm, the outer diameter is 80 mm, the outer height is 80 mm, and the inner cavity height is 60 mm; the inner crucible is only used to hold raw materials (put in the crucible Bottom) and seed crystal (installed on the inner surface of the crucible lid), with an inner diameter of 30 mm, an outer diameter of 40 mm, an outer height of 50 mm, and an inner cavity height of 40 mm. The inner crucible is coaxially placed on the bottom of the outer crucible, and the inner and outer crucibles are sealed by crucible lids. After the growth is over, open the outer crucible cover, take out the inner crucible from the outer crucible, saw the inner crucible, and take out a 1-inch diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com