Waterproof synergistic agent and method for improving textile water-proof finish

A synergist and textile technology, applied in the direction of textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of inability to use, achieve the effect of low price, reduce surface tension, and good self-emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

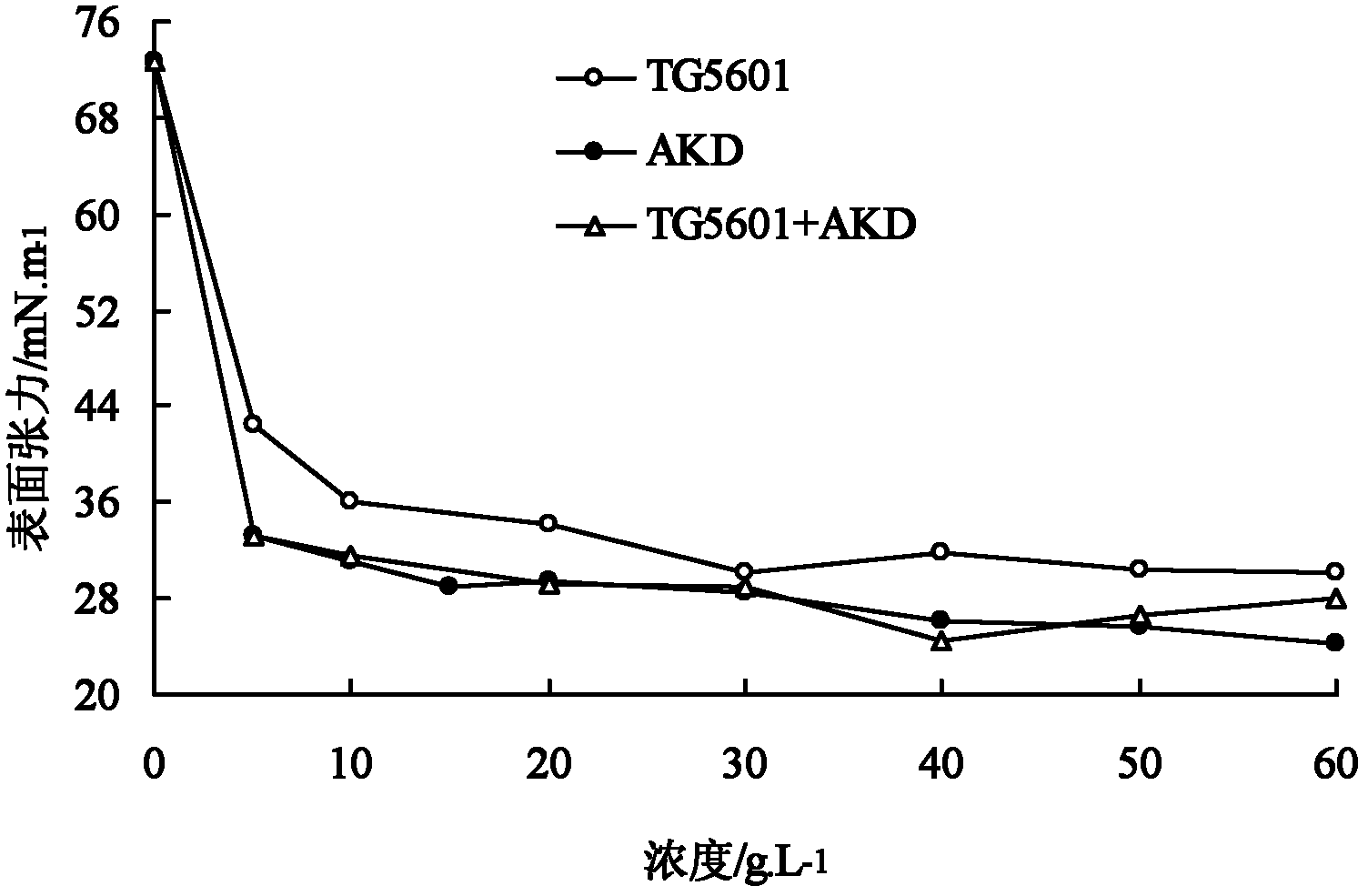

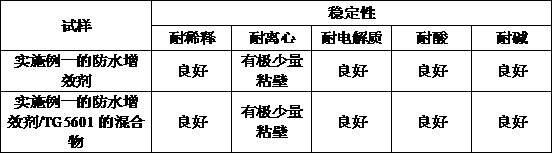

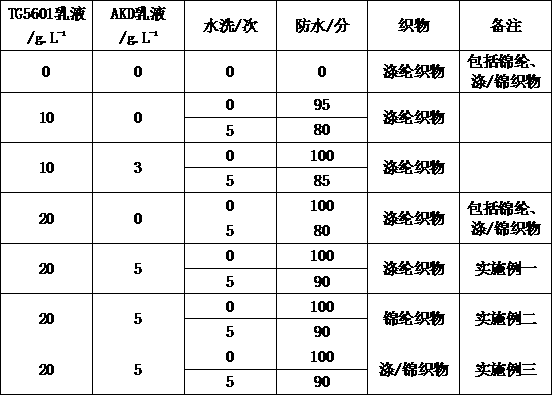

[0027] Add 1.27Kg of octadecyl dimethyl hydroxyethyl quaternary ammonium salt, 0.78Kg of secondary alcohol polyoxyethylene ether (8), 0.26 Kg of paraffin emulsifier and 90Kg of water into a 500Kg reaction kettle, and heat up while stirring to 60~65℃, then slowly add 7.69KgC which has been preheated at 60~65℃ 16-18 Advanced alkyl ketene dimer, fully stirred to get 10% concentration of waterproof synergist.

[0028] Take 0.5Kg of the above-mentioned waterproof synergist, and 2.0 Kg of commercially available TG5601 (C 6 Perfluoroacrylic acid waterproofing agent) mixed, added to 97.5Kg of water, prepared waterproofing agent solution. Then, pad the polyester fabric with the above water-repellent agent solution, and the excess rate is 55-60%, and then dry and treat it at high temperature (170°C) for 3 minutes on a hot-air stenter setting machine to obtain a polyester fabric with waterproof function.

Embodiment 2

[0030] Add 0.67Kg octadecyl dimethyl hydroxyethyl quaternary ammonium salt, 0.50Kg secondary alcohol polyoxyethylene ether (8), 0.16 Kg paraffin emulsifier and 92Kg water into a 500Kg reaction kettle, and heat up while stirring to 60-65°C, then slowly add 6.67KgC preheated at 60-65°C 16-18 Advanced alkyl ketene dimer, fully stirred to get 8% concentration of waterproof synergist.

[0031] According to the method of embodiment one, handle polyamide fiber, obtain the nylon fabric with waterproof function.

Embodiment 3

[0033]Add 1.48Kg of octadecyl dimethyl hydroxyethyl quaternary ammonium salt, 0.99Kg of secondary alcohol polyoxyethylene ether (8), 0.33 Kg of paraffin emulsifier and 85Kg of water into a 500Kg reaction kettle, and heat up while stirring to 60~65℃, then slowly add 11.20KgC which has been preheated at 60~65℃ 16-18 Advanced alkyl ketene dimer, fully stirred to get 14% concentration of waterproof synergist.

[0034] According to the method of Example 1, the polyester / polyamide ultrafine composite fiber is processed to obtain a polyester / brocade fabric with waterproof function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com