Flame-retardant high-toughness carbon fiber composite material for overhead transmission conductor

A technology for overhead power transmission wires and composite materials, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, rayon manufacturing, etc., and can solve the problems of limited toughness improvement of carbon fiber composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

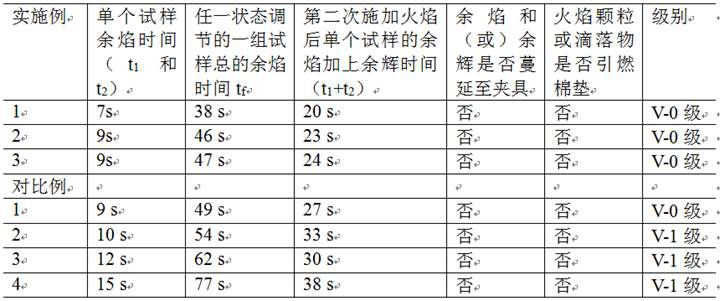

Examples

Embodiment 1

[0033] A flame-retardant high-toughness carbon fiber composite material for overhead power transmission wires, made of the following components by weight: 55 parts of polyacrylonitrile, 23 parts of single-layer graphene powder, 10 parts of bacterial cellulose, and 6 parts of methyl methacrylate , 8 parts of 1,6-dibromohexane, 35 parts of thermosetting resin, 3 parts of nano-magnesium hydroxide, and 5 parts of nano-aerogel.

[0034] The thermosetting resin is epoxy resin, F46, from Shanghai Resin Factory Co., Ltd.

[0035] The curing agent is hexamethylenetetramine.

Embodiment 2

[0037] A flame-retardant high-toughness carbon fiber composite material for overhead transmission wires, made of the following components by weight: 50 parts of polyacrylonitrile, 20 parts of single-layer graphene powder, 8 parts of bacterial cellulose, and 5 parts of methyl methacrylate , 5 parts of 1,6-dibromohexane, 30 parts of thermosetting resin, 1 part of nano-magnesium hydroxide, and 3 parts of nano-aerogel.

[0038] The thermosetting resin is phenolic resin.

[0039] The curing agent is hexamethylenetetramine.

Embodiment 3

[0041] A flame-retardant high-toughness carbon fiber composite material for overhead transmission wires, made of the following components by weight: 60 parts of polyacrylonitrile, 30 parts of single-layer graphene powder, 15 parts of bacterial cellulose, and 10 parts of methyl methacrylate , 10 parts of 1,6-dibromohexane, 40 parts of thermosetting resin, 5 parts of nano-magnesium hydroxide, and 6 parts of nano-aerogel.

[0042] The thermosetting resin is epoxy resin.

[0043] The curing agent is polyetheramine D230.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com