A storage-resistant epoxy carbon fiber prepreg and preparation method thereof

A technology of carbon fiber prepreg and epoxy resin, which is applied in the field of polymer materials, can solve the problems affecting the use of carbon fiber prepreg and short storage period, and achieve improved thermal oxygen resistance and ultraviolet radiation resistance, good stability, easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

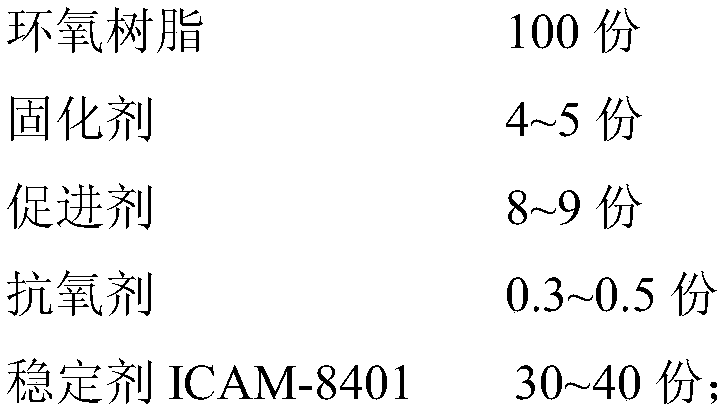

Method used

Image

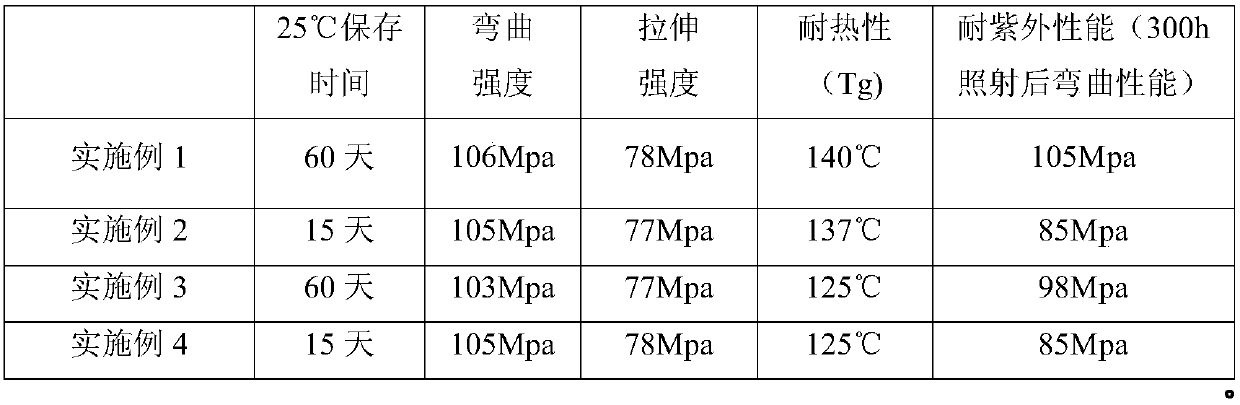

Examples

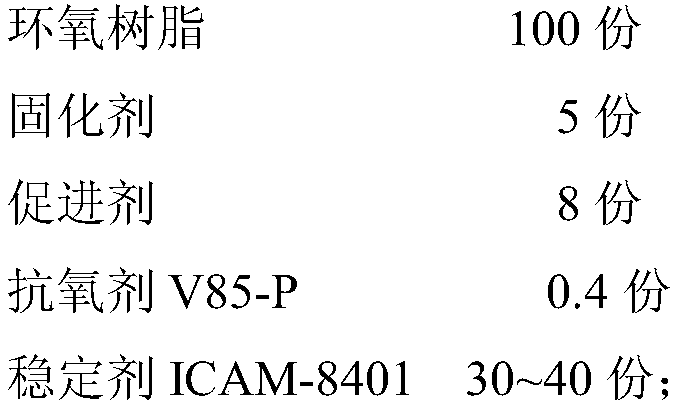

Embodiment 1

[0031] 1) Put 670 grams of solid epoxy resin 901 and 330 grams of liquid epoxy resin in a 2000 ml glass flask with a vacuum device, and stir at 120°C for 30 minutes to obtain solution A, which is directly used in the next reaction;

[0032] 2) Add 50 grams of curing agent dicyandiamide 100S to solution A in the previous step, and stir at 70°C for 30 minutes to obtain mixture B.

[0033] 3) Add 8 grams of accelerator UR500 to the mixture B in the previous step, and stir at 70°C for 10 minutes to obtain mixture C.

[0034] 4) Put the mixture C of the previous step, 30 grams of stabilizer ICAM-8401 and 4 grams of antioxidant V85-P in a 2000 ml glass flask with a vacuum device, and stir at 70°C for 20 minutes to obtain solution D;

[0035] Put the solution D in the gluing machine at 70°C, detect the thickness of the film or the surface density of the film with an infrared instrument, and lower the temperature of the film through the cooling plate to reduce its curing degree to pre...

Embodiment 2

[0037] No stabilizer ICAM-8401 was added, and the rest were the same as in Example 1.

[0038] 1) Put 670 grams of solid epoxy resin 901 and 330 grams of liquid epoxy resin in a 2000 ml glass flask with a vacuum device, and stir at 120 ° C for 30 minutes to obtain solution A, which is directly used in the next reaction;

[0039] 2) Add 50 grams of curing agent dicyandiamide 100S to solution A in the previous step, and stir at 70°C for 30 minutes to obtain mixture B.

[0040] 3) Add 8 grams of accelerator UR500 to the mixture B in the previous step, and stir at 70°C for 10 minutes to obtain mixture C.

[0041] 4) Put the mixture C of the previous step and 4 grams of antioxidant V85-P in a 2000 ml glass flask with a vacuum device, and stir at 70°C for 20 minutes to obtain solution D;

[0042] Put the solution D in the gluing machine at 70°C, detect the thickness of the film or the surface density of the film with an infrared instrument, and lower the temperature of the film thr...

Embodiment 3

[0044] No antioxidant V85-P was added, and the rest were the same as in Example 1.

[0045] 1) Put 670 grams of solid epoxy resin 901 and 330 grams of liquid epoxy resin in a 2000 ml glass flask with a vacuum device, and stir at 120 ° C for 30 minutes to obtain solution A, which is directly used in the next reaction;

[0046] 2) Add 50 grams of curing agent dicyandiamide 100S to solution A in the previous step, and stir at 70°C for 30 minutes to obtain mixture B.

[0047] 3) Add 8 grams of accelerator UR500 to the mixture B in the previous step, and stir at 70°C for 10 minutes to obtain mixture C.

[0048] 4) Put the mixture C of the previous step and 40 grams of stabilizer ICAM-8401 in a 2000 ml glass flask with a vacuum device, and stir at 70°C for 20 minutes to obtain solution D;

[0049] Put the solution D in the gluing machine at 70°C, detect the thickness of the film or the surface density of the film with an infrared instrument, and lower the temperature of the film th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com