Coating composition dispersion, aqueous composite-particle dispersion, and process for producing aqueous composite-particle dispersion

A technology for water-based composite particles and coating compositions, which can be used in coatings, latex paints, etc., and can solve the problems of poor dispersion stability and cohesion of mixed compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

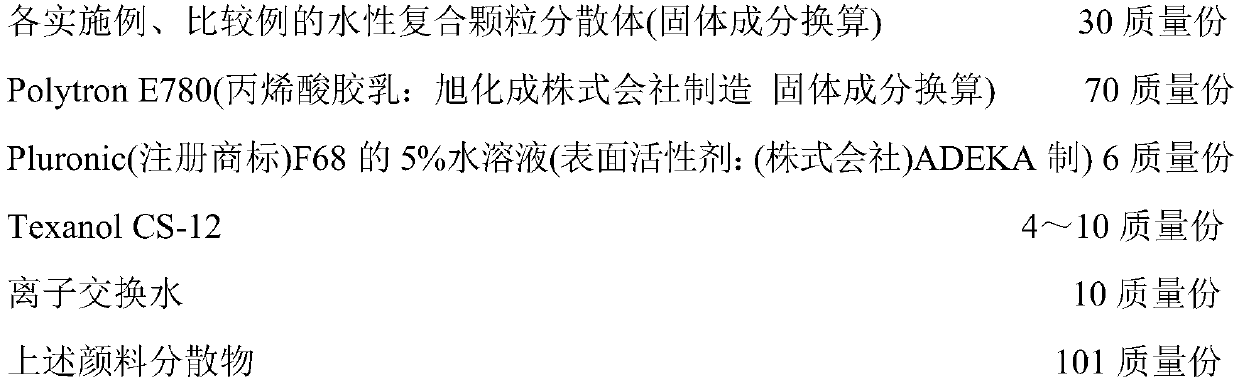

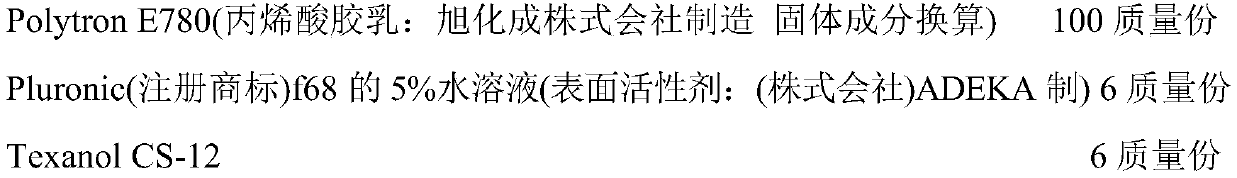

[0533] [Examples 1-13] [Comparative Examples 1-3]

[0534] The measurement methods and raw materials used in Examples and Comparative Examples are shown below.

[0535] [Quantitative Analysis Method of Mass of Phosphorus Atoms Relative to Total Mass of Composite Particles]

[0536] Quantification of phosphorus atoms relative to the total mass of composite particles is carried out by dialyzing a desired latex sample while maintaining alkalinity, followed by freeze-drying, and performing ICP emission analysis on the obtained sample. .

[0537] The detailed procedure is as follows.

[0538] (1) Dialysis and drying of latex samples

[0539] Dilute the aqueous composite particle dispersion with 0.001 equivalent NaOH (1.0mM NaOH aqueous solution) to 20 times, and filter it on multiple ultrafiltration membranes (Vivaspin 6, molecular weight cut-off: 100,000 (100K), membrane material: PES, manufactured by Sartorius StedimBiotech Gmbh) An appropriate volume of the diluted aqueous c...

Synthetic example 1

[0652] [Synthesis Example 1 (Synthesis of High Molecular Polymer Particles (A))]

[0653] Aquaron (registered trademark) KH-10 (polyoxyethylene-1-(alkyloxymethyl) with concentration adjusted to 15% by mass was added to a reaction vessel equipped with a stirrer, a reflux cooler, a dropping tank, and a thermometer. Base) Alkyl ether ammonium sulfate, manufactured by Daiichi Kogyo Sangyaku Co., Ltd.) 40 g, the temperature in the reaction vessel was raised to 78° C. under a nitrogen atmosphere, and then 15 g of a 2% aqueous solution of ammonium persulfate was added.

[0654] After 5 minutes, a mixture of the following substances, 50 g of 2% aqueous solution of ammonium persulfate and 700 g of ion-exchanged water was flowed into the reactor for 180 minutes: 185 g of methyl methacrylate, 300 g of cyclohexyl methacrylate, methacrylic acid Butyl 200g, 2-ethylhexyl acrylate 250g, 2-hydroxyethyl methacrylate 50g, methacrylic acid 10g, acrylic acid 5g, PPME (2-methacryloxyethyl phosphate...

Embodiment 1

[0659] After adjusting the aqueous dispersion of the high molecular polymer particle (A) of the above [Synthesis Example 1] to pH 9.5 with ammonia, water was added to adjust the concentration to 40.0% by mass, and 250.0 g of it was dropped into a reflux cooler, dripping In the reactor of the liquid tank, the thermometer and the stirring device, the temperature was raised to 60°C.

[0660] Aquaron (registered trademark) KH-10 (30 g) adjusted to a concentration of 10% by mass was slowly added thereto.

[0661] After raising the temperature of the dispersion in the reactor to 70° C. under a nitrogen atmosphere, 45 g of ammonium persulfate (2% aqueous solution) was added.

[0662] After 5 minutes, 3.2 g of methyl methacrylate, 4.8 g of cyclohexyl methacrylate, 7.76 g of butyl acrylate and PPME (methacryloyloxy ethyl phosphate, Toho Chemical Industry Co., Ltd.) 0.24g, Neopelex (registered trademark) G-15 (aqueous solution of sodium dodecylbenzenesulfonate, manufactured by Kao Corp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com